Manufacturing method for array substrate for liquid crystal display device

A technology for liquid crystal display devices and array substrates, applied in nonlinear optics, instruments, optics, etc., which can solve problems such as overheating, decreased storage stability, and no longer conforming to users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

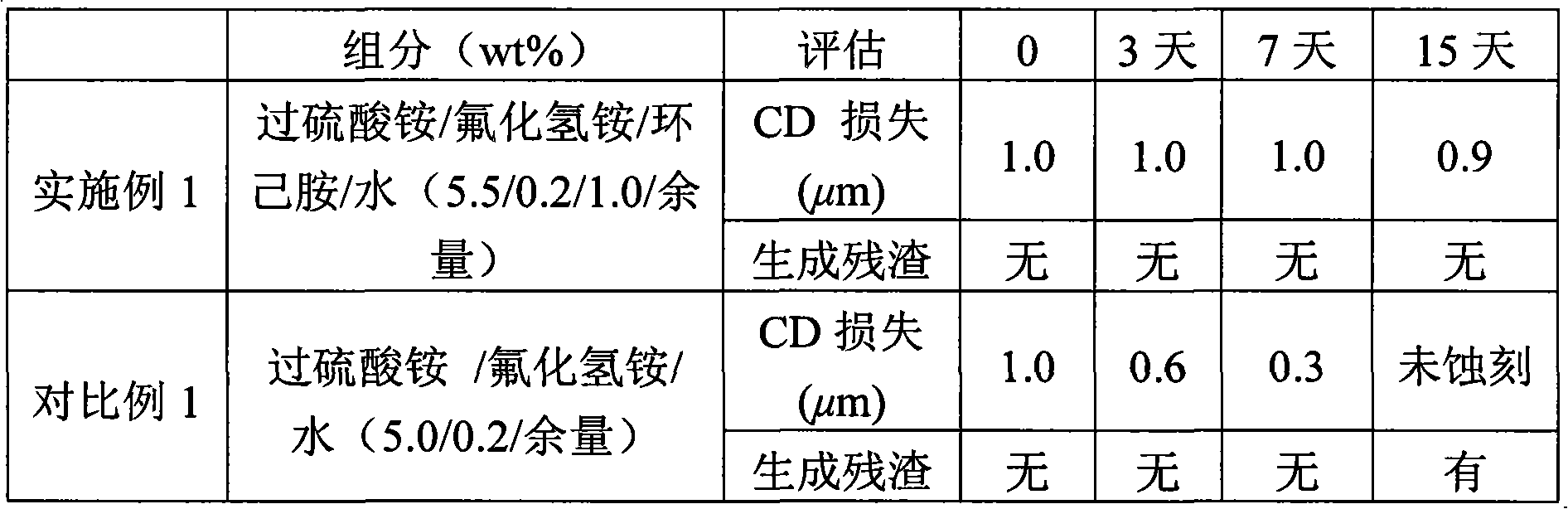

[0038] Example 1 and Comparative Example 1: Preparation of etching solution composition and evaluation of etching performance

[0039] The etching solution compositions of Example 1 and Comparative Example 1 were prepared using the amounts of the components shown in Table 1 below. Additionally, they are used to etch Cu / Ti bilayers.

[0040]

[0041] The etching solution compositions of each of Example 1 and Comparative Example 1 were put into a spray etching machine (model name: ETCHER (TFT), obtained from SEMES Corporation), and then heated at a set temperature of 25°C. Subsequently, an etching process is performed at 30±0.1°C. Subsequently, the test samples were placed in a spray etcher, and each solution was sprayed for etching. After the etching was completed, the test sample was taken out from the etching machine, cleaned with deionized water, dried with a hot air dryer, and then the photoresist was removed with a photoresist stripper. After cleaning and drying, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com