Oven

A technology of an oven and a baking basket, applied in the field of ovens, can solve the problems of large size of fixtures, prone to scalds, inconvenient storage, etc., and achieves the effects of simple and reasonable design, prevention of scalding accidents, and easy access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

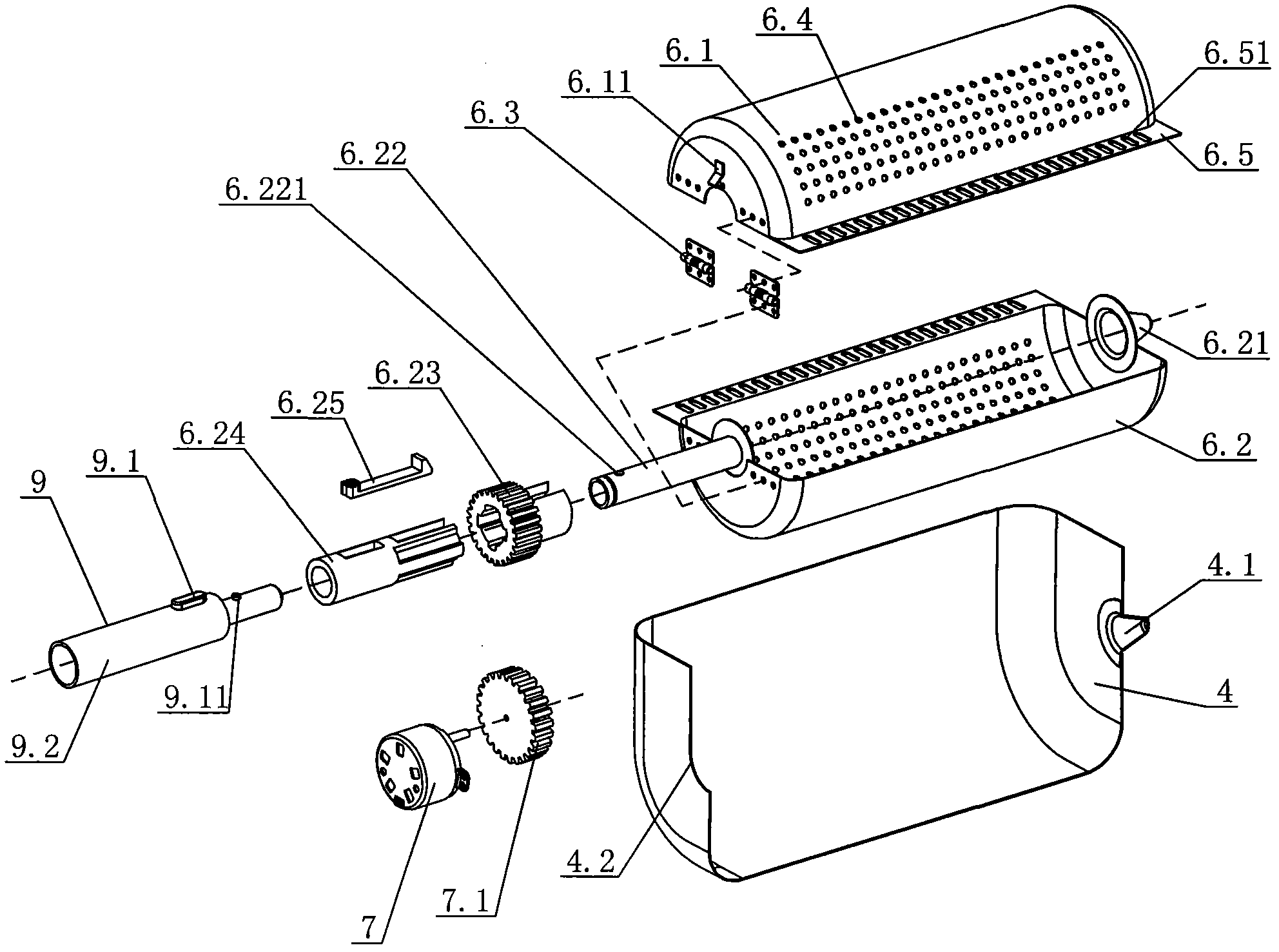

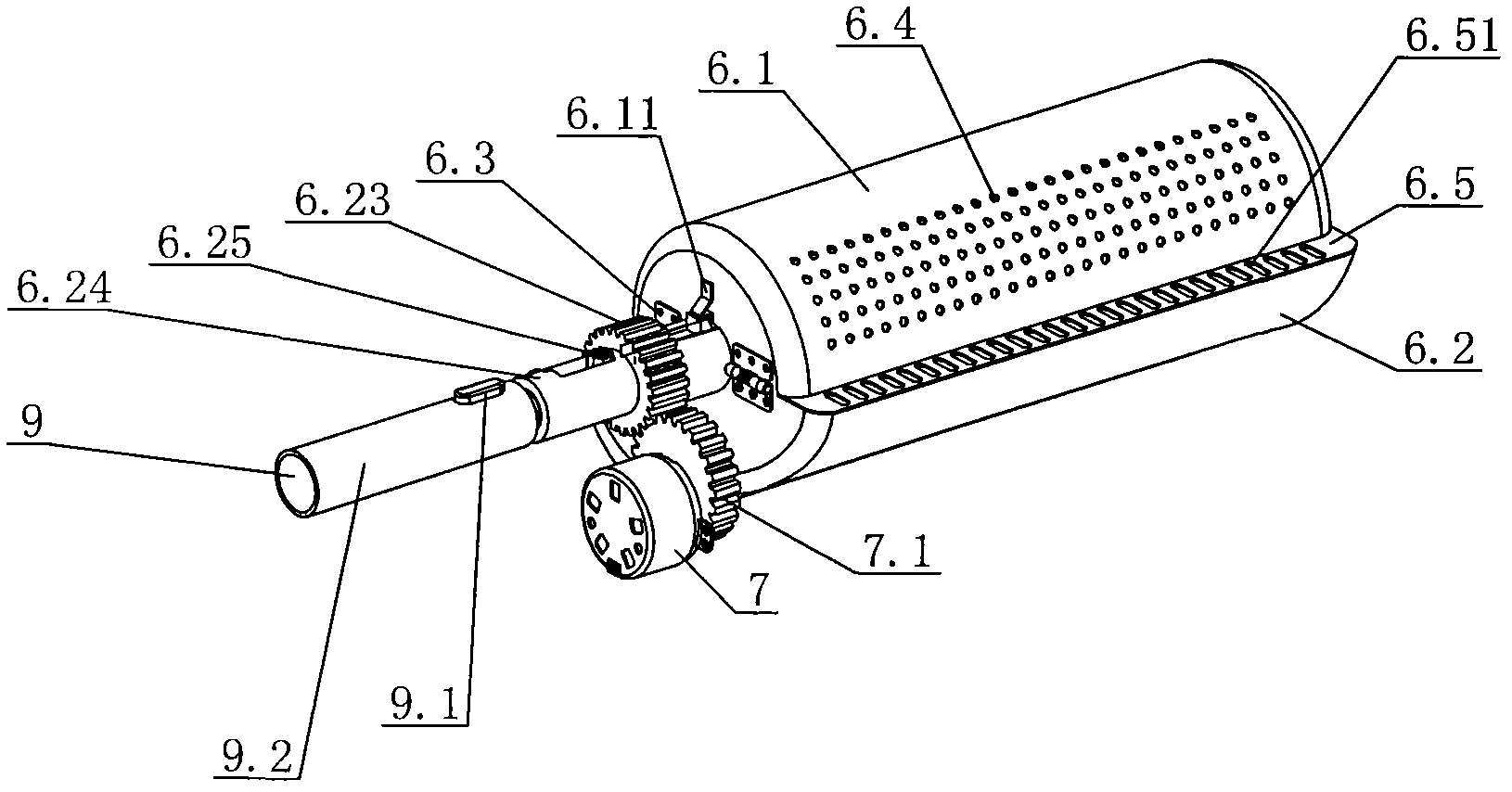

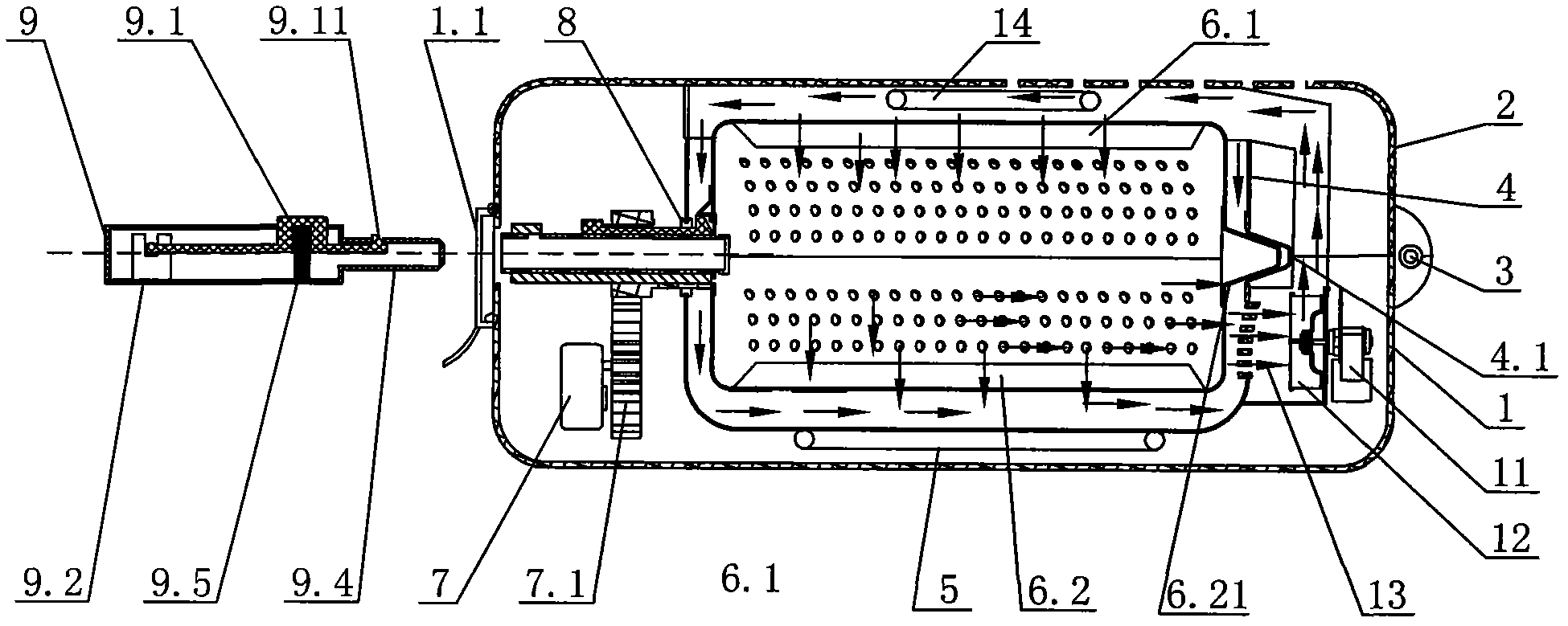

[0026] see Figure 1-Figure 9 , this oven includes a main body 1 provided with an inner container 4, and a drum-type baking basket assembly 6 that can be rotated by a drive motor 7 is installed in the inner container 4, and the drum-type baking basket assembly 6 includes an upper and lower opening and closing connection The upper baking basket 6.1 and the lower baking basket 6.2, the drum-type baking basket assembly 6 is provided with a rotating shaft 6.22 coupled with the drive motor 7, the drum-type baking basket assembly 6 is detachably connected with a handle assembly 9, and the inner container 4 is provided with Internal recirculation airflow assembly.

[0027] see figure 1 , figure 2 , the upper baking basket 6.1 and the lower baking basket 6.2 are in the shape of a semi-cylindrical, one end of the round bottom of the two is opened and closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com