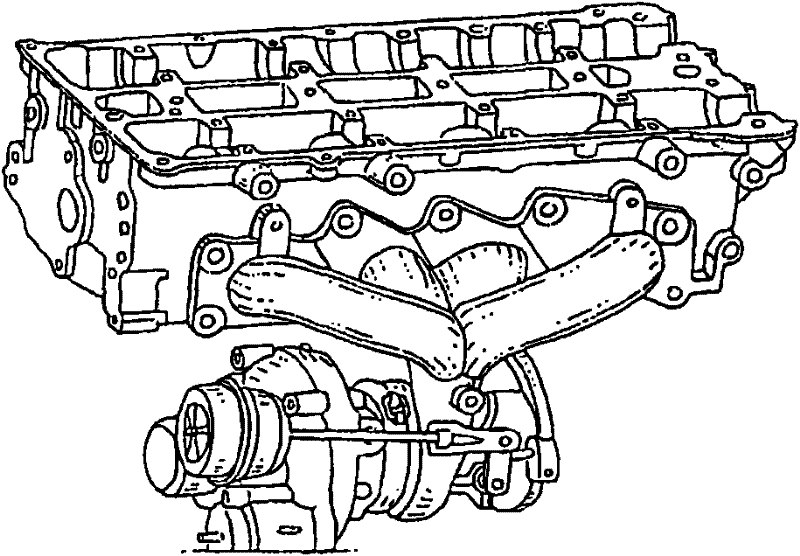

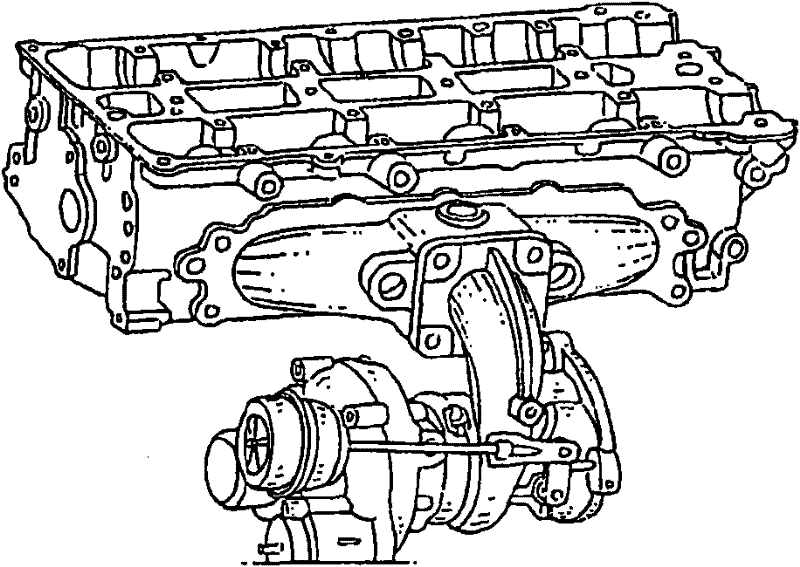

Motor arrangement with integrated exhaust gas manifold

A technology for engines and exhaust pipes, applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as increased manufacturing costs and difficulties in thermal power, and achieve the effects of saving materials, improving response characteristics, and improving fuel consumption values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

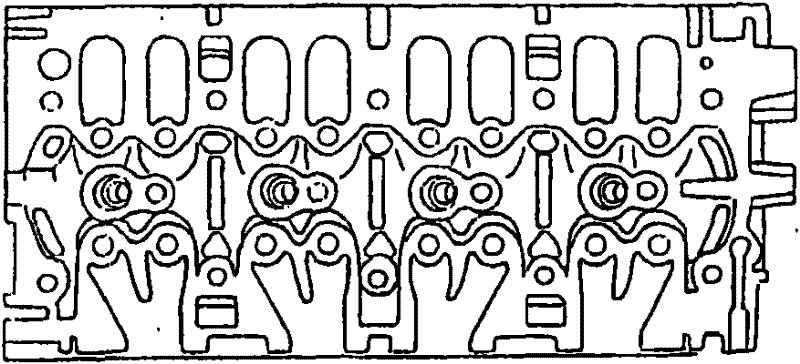

[0044] An engine device with an internal combustion engine according to the invention has a cylinder block with at least two cylinders, each of which is Figure 14 Shown is at least one exhaust opening 20 , which can be selectively closed by means of an exhaust valve, and which is used for discharging exhaust gas. The exhaust gas discharged from each exhaust port 20 is guided by an exhaust pipe 30, which is preferably merged into a total exhaust pipe 60 mainly in the cylinder head 100, wherein the exhaust passage arranged in the cylinder head 100 is provided by the exhaust pipe arranged in the cylinder head 100 The coolant channel 40 near the exhaust port is cooled by liquid cooling. The protruding area 110 integrated in the cylinder head is likewise cooled by the liquid, so that the connecting surface of the first exhaust-gas flow device can be configured in a weight-saving manner. To enhance liquid cooling, this region 110 can also protrude less and, in particular, can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com