Battery charging preheating device and system

A battery charging and preheating device technology, applied in secondary battery charging/discharging, secondary battery, secondary battery repair/maintenance, etc., can solve the problem of unstable current value, heat generation, slow lithium battery preheating speed, etc. problems, to achieve the effect of increasing the warm-up speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

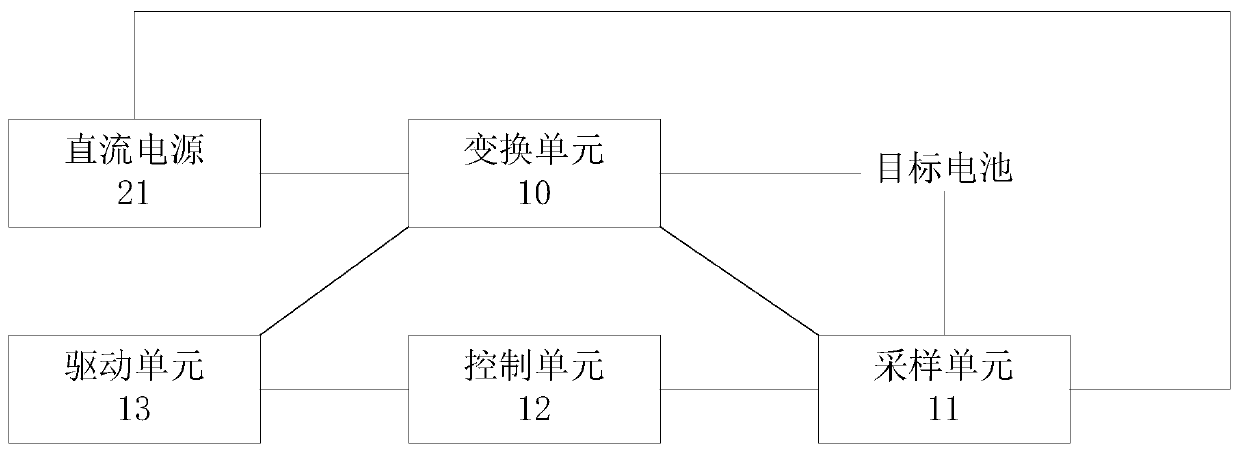

[0039] An embodiment of the present invention provides a battery charging preheating device, such as figure 1 As shown, the device includes: a transformation unit 10, a sampling unit 11, a control unit 12 and a drive unit 13;

[0040] The first input end and the second input end of the above-mentioned transformation unit 10 are respectively connected with the first output end of the DC power supply and the output end of the drive unit 13; the first output end and the second output end of the transformation unit 10 are respectively connected with the target battery The input end is connected with the first input end of the sampling unit 11; the second input end and the third input end of the sampling unit 11 are respectively connected with the second output end of the DC power supply and the output end of the target battery; the input end of the control unit 12 is connected with the output end of the target battery. The output end is respectively connected with the output end o...

Embodiment 2

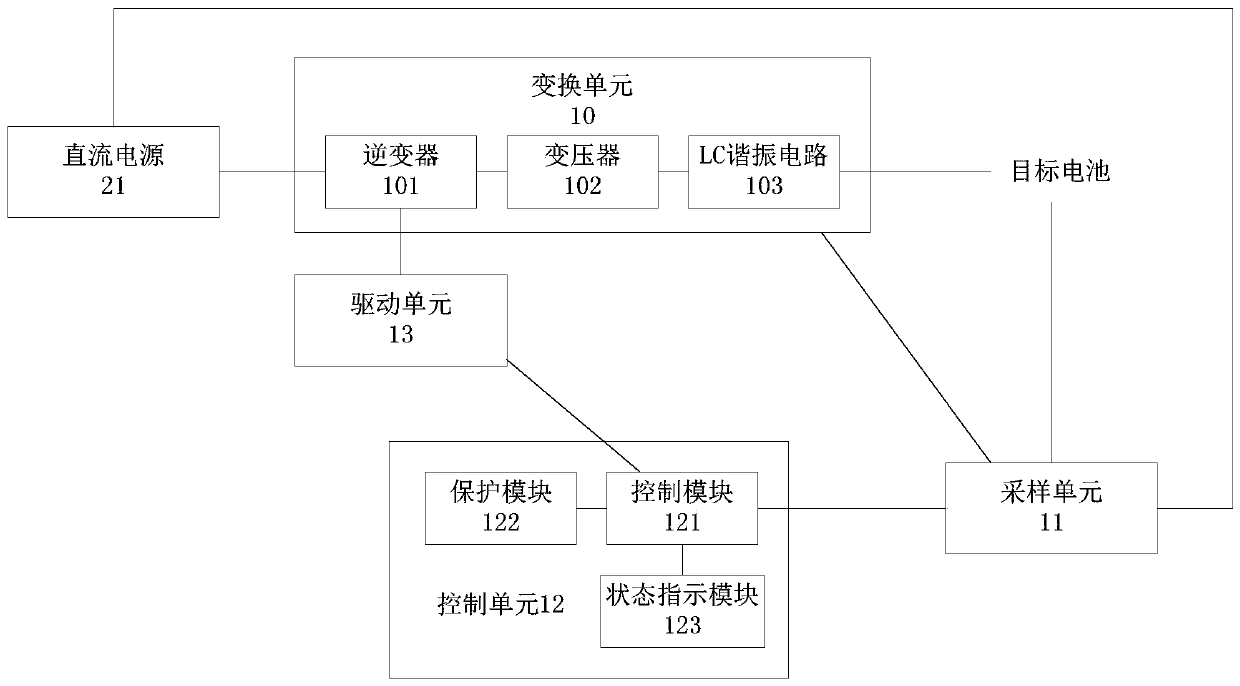

[0047] The embodiment of the present invention also provides another battery charging preheating device, which is implemented on the basis of the first embodiment, as figure 2 As shown, the conversion unit 10 includes an inverter bridge 101, a transformer 102 and an LC resonant circuit 103 connected in sequence; the control unit 12 includes a control module 121, a protection module 122 and a status indicating module 123;

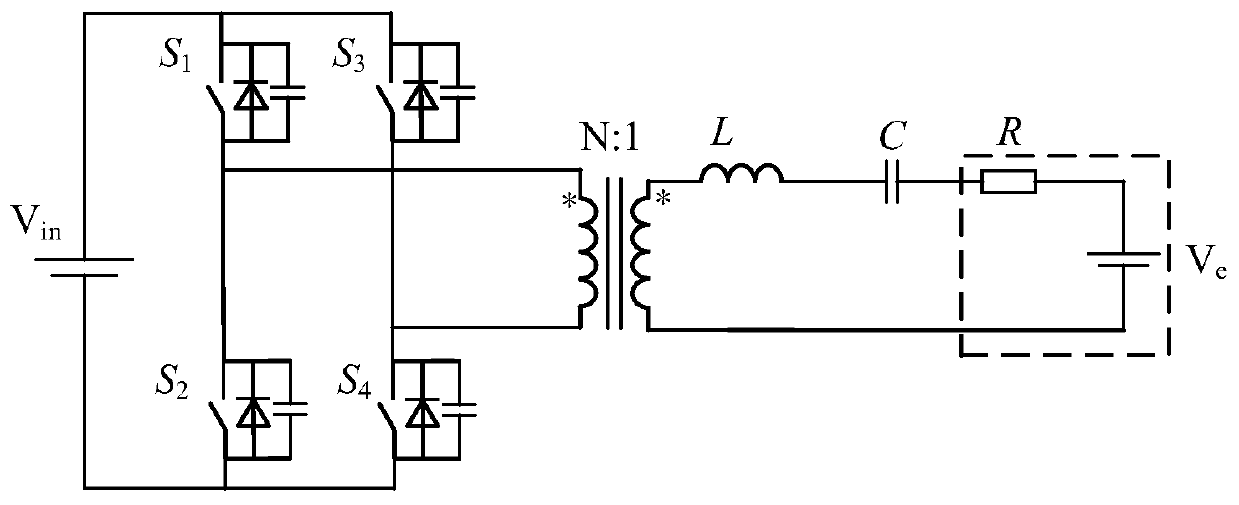

[0048] The above-mentioned transformer 102 can be a high-frequency transformer, and the ratio of the number of turns of the primary side to the number of turns of the secondary side is N:1. The transformer is connected to the primary side circuit and the secondary side circuit to play a role of safety isolation. The secondary side, and the primary side AC voltage pulse is converted to the secondary side voltage pulse according to the transformation ratio, which is used to generate resonance in the LC resonant circuit, and is used to convert the voltage value...

Embodiment 3

[0094] The embodiment of the present invention also provides a battery charging preheating system, such as Figure 13 As shown, the system includes the battery charging and preheating device 20 in Embodiment 1 or Embodiment 2, and also includes a DC power supply 21 connected to the battery charging and preheating device 20 .

[0095]The embodiment of the present invention provides a battery charging preheating device and system, the device includes: a conversion unit, a sampling unit, a control unit and a drive unit; the first input end and the second input end of the conversion unit are respectively connected to the output connected to the output end of the driving unit; the first output end and the second output end of the conversion unit are respectively connected to the input end of the target battery and the first input end of the sampling unit; the second input end of the sampling unit is connected to the output of the target battery The input terminal and the output ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com