LED vehicle lamp efficient cooling module

A technology of LED lights and heat dissipation modules, which is applied in the direction of motor vehicles, road vehicles, vehicle parts, etc., can solve the problems of general heat dissipation, increased volume and weight, and easy aging, so as to improve heat conduction efficiency, area and quality Effect of reducing and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

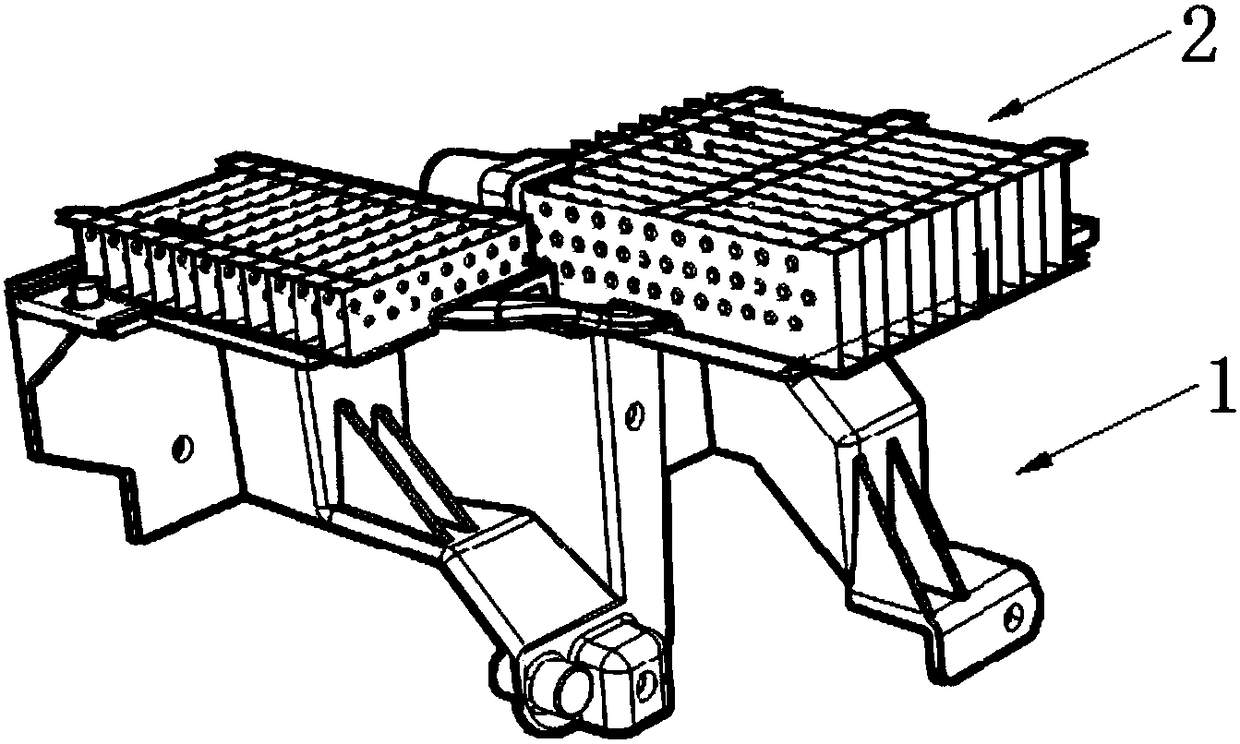

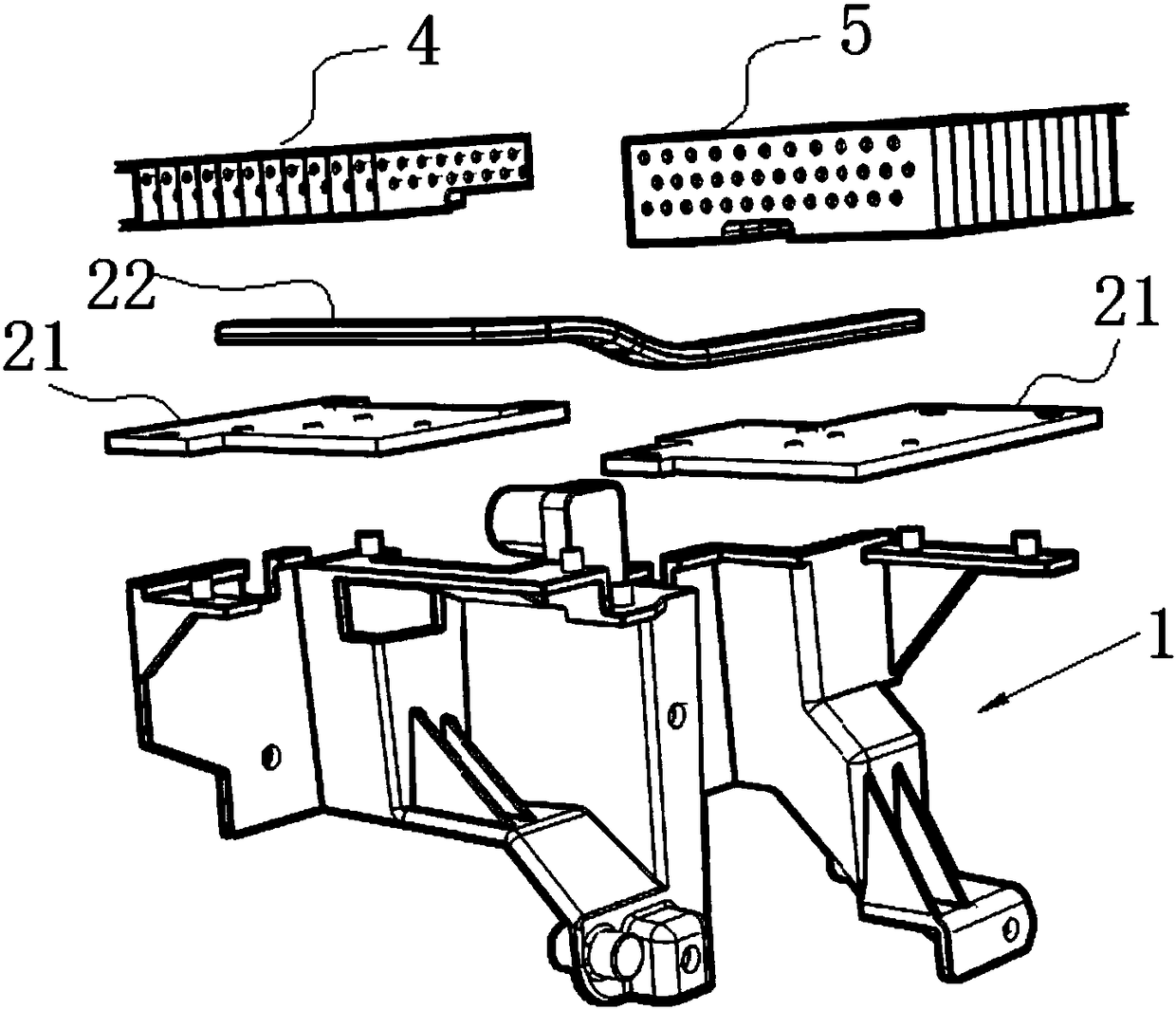

[0039] Embodiment: a kind of high-efficiency heat dissipation module of LED car lamp, such as Figure 1-Figure 5 As shown, it includes a support frame 1, a car lamp substrate (not shown in the figure) and a heat dissipation structure 2. The heat dissipation structure 2 includes a heat dissipation substrate 21, a heat pipe 22 and a fin structure, and the heat pipe 22 is fixed on the heat dissipation substrate 21 and the fin structure. Between the fin structures, the heat dissipation substrate 21 is fixed above the support frame 1 , and the lamp substrate is fixed below the heat dissipation substrate 21 ;

[0040] The upper surface of the heat pipe 22 communicates with the fin structure, and the lower surface of the heat pipe 22 communicates with the heat dissipation substrate;

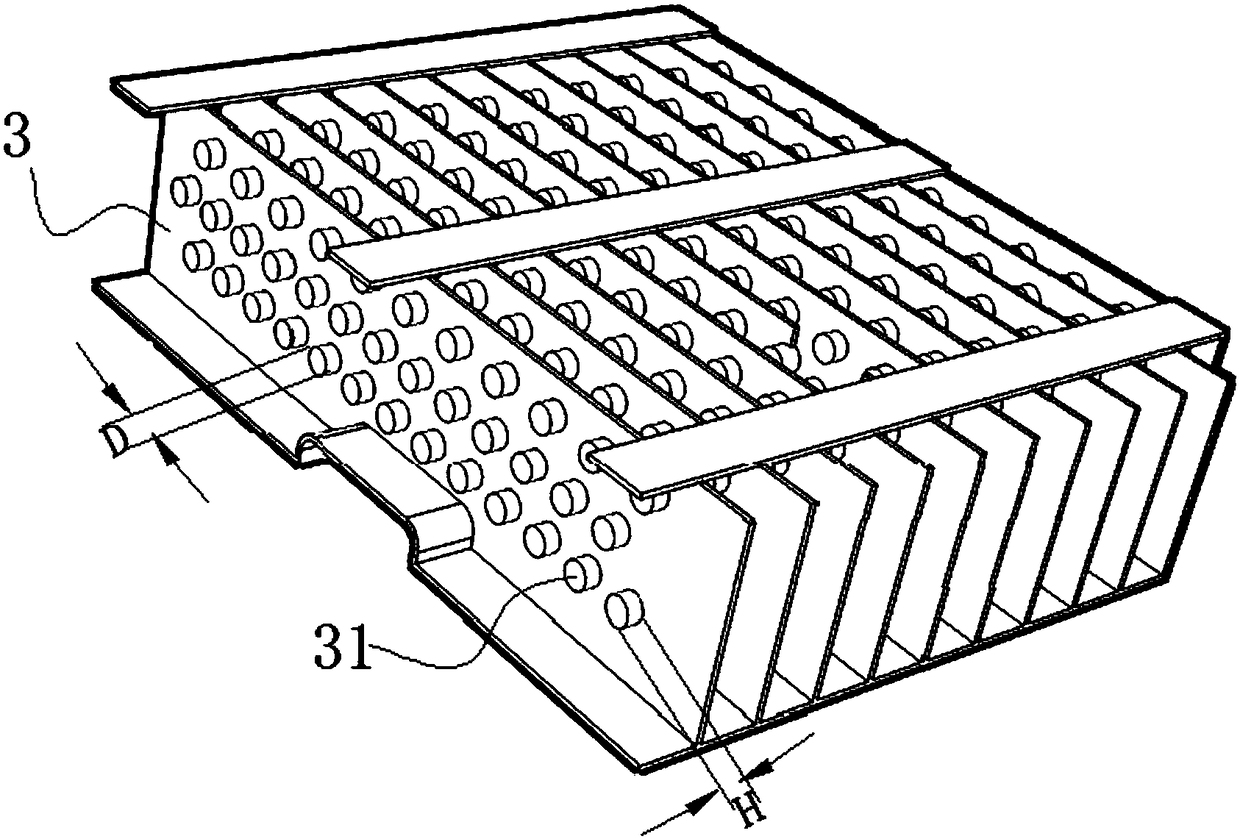

[0041] The fin structure includes a number of fins 3 distributed at equal intervals and perpendicular to the heat dissipation substrate, each side of the fin 3 is evenly distributed with several rows of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com