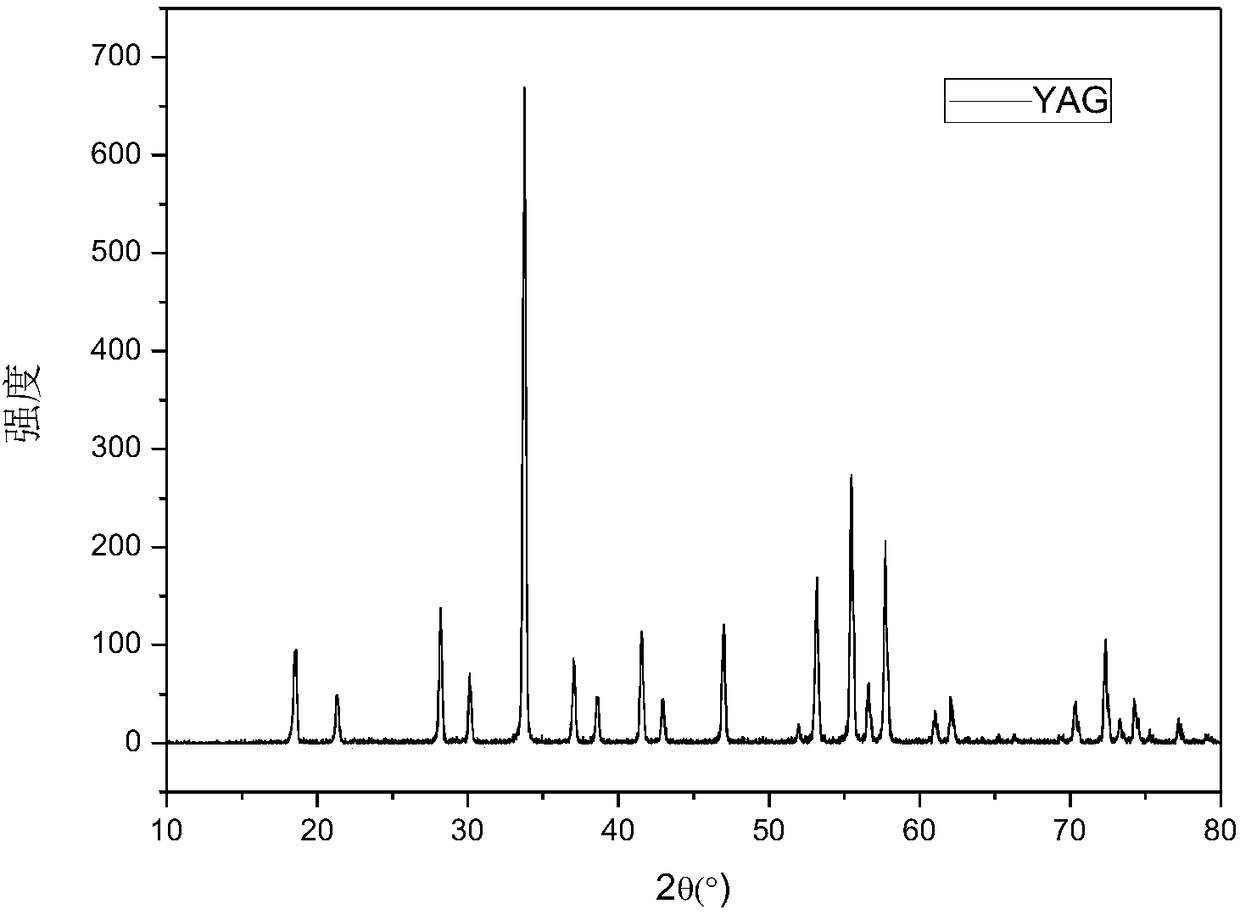

YAG fluorescent ceramic as well as preparation method and application thereof

A technology of fluorescent ceramics and luminescent centers, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve problems such as poor thermal conductivity, high color temperature, and reduced luminous efficiency, so as to facilitate industrial production, promote densification, and avoid light Fading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

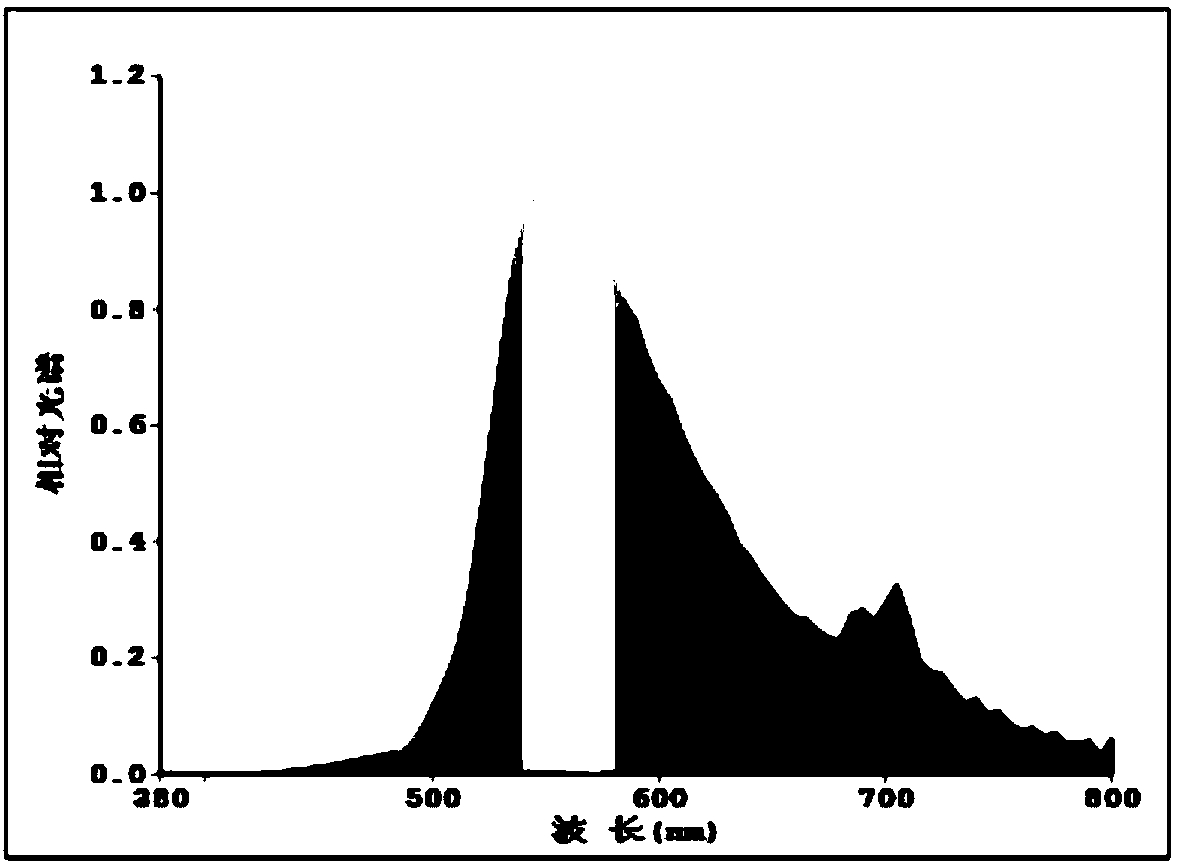

Embodiment 1

[0094] α-alumina (α-Al 2 o 3 ), yttrium oxide (Y 2 o 3 ), cerium oxide (CeO 2 ), chromium trioxide (Cr 2 o 3 ) is the reaction raw material, with magnesium oxide (MgO) and tetraethyl orthosilicate (TEOS) as the sintering aid; according to (Y 1-0.02 Ce 0.02 ) 3 (Al 1- 0.0003 Cr 0.0003 ) 5 o 12 Strictly calculate the mass required for each raw material and accurately weigh a total of 10g of mixed powder raw materials, and add sintering aids 0.05wt% MgO (the total mass of mixed powder raw materials is the base) and 0.5wt% TEOS (mixed powder The total mass of bulk raw materials is the base number). Using absolute ethanol (mass ratio EtOH: mixed powder raw material = 1:1) as the medium, use alumina ball milling, dry the slurry (rotary evaporator first evaporates to remove the organic solvent, and then moves to 80 ° C for drying Keep drying in the box for 5h), sieve (the mesh number of the sieve is 200 mesh) to obtain the mixed powder. After dry pressing (15MPa), the ...

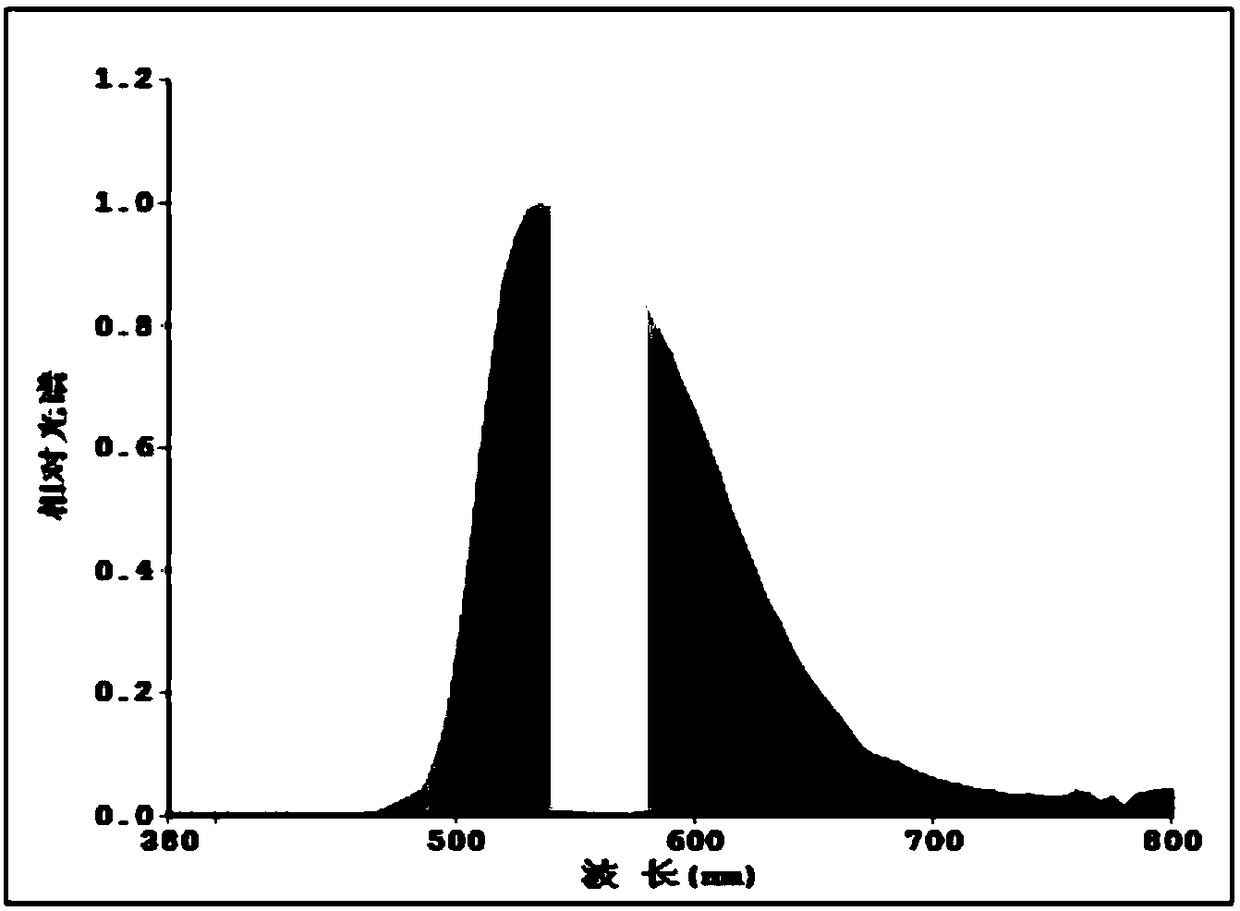

Embodiment 2

[0096] Adopt and prepare with the preparation method in embodiment 1 (Y 1-0.004 Ce 0.004 ) 3 (Al 1-0.0003 Cr 0.0003 ) 5 o 12 Fluorescent ceramics, the ceramics are marked as 2#.

Embodiment 3

[0098] Adopt and prepare with the preparation method in embodiment 1 (Y 1-0.006 Ce 0.006 ) 3 (Al 1-0.0003 Cr 0.0003 ) 5 o 12 Fluorescent ceramics, the ceramics are marked as 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com