High-temperature solar selective absorbing coating and preparation method thereof

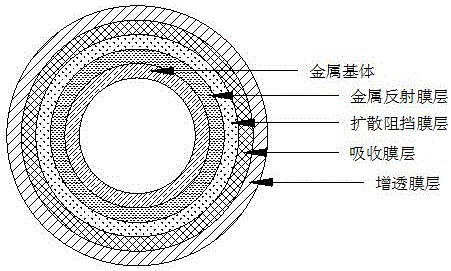

A technology that absorbs coatings and solar energy. It is applied in the field of solar energy utilization. It can solve the problems of increasing the cost of the coating, the decay of the optical properties of the coating, and the failure of the coating to achieve enhanced hardness and wear resistance, enhanced process stability, and target materials. Effect of Utilization Ratio Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

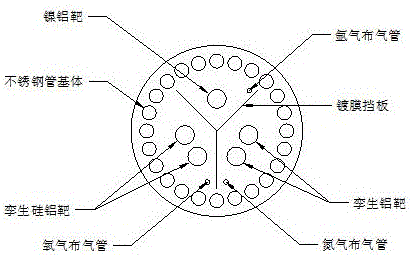

[0038] This embodiment provides a method for preparing a high-temperature solar energy selective absorption coating. The method uses an intermediate frequency and pulsed DC vacuum magnetron sputtering coating machine as the process equipment. The vacuum chamber structure of the coating machine equipment is as follows: figure 2 As shown, the substrate is fixed at the edge of the vacuum chamber, and the substrate itself can rotate around the center of the vacuum chamber. The aluminum target, nickel-aluminum target and silicon-aluminum target are cylindrical magnetrons. For the sputtering target, the distance between the aluminum target, the silicon-aluminum target and the metal substrate is 15 cm, and the distance between the nickel-aluminum target and the metal substrate is 5 cm. The magnetic field arrangement of the cylindrical magnetron sputtering target is an unbalanced magnetic field. Due to the divergence of the unbalanced magnetic field, the effective coating area of th...

Embodiment 2

[0053] This embodiment provides a method for preparing a high-temperature solar energy selective absorption coating. The method uses an intermediate frequency and pulsed DC vacuum magnetron sputtering coating machine as the process equipment. The vacuum chamber structure of the coating machine equipment is as follows: figure 2 As shown, the substrate is fixed at the edge of the vacuum chamber, and the substrate itself can rotate around the center of the vacuum chamber. The aluminum target, nickel-aluminum target and silicon-aluminum target are cylindrical magnetrons. For the sputtering target, the distance between the aluminum target, the silicon-aluminum target and the metal substrate is 25 cm, and the distance between the nickel-aluminum target and the metal substrate is 15 cm. The magnetic field arrangement of the cylindrical magnetron sputtering target is an unbalanced magnetic field. Due to the divergence of the unbalanced magnetic field, the effective coating area of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com