Conductive heat-conducting foam adhesive tape and production method thereof

A technology of electric conduction and heat conduction and production method, which is applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problems of tape conduction and heat conduction efficiency reduction, graphite layer cracking, peeling, etc., to avoid heat conduction effect reduction, improve electrical conductivity, Guaranteed uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

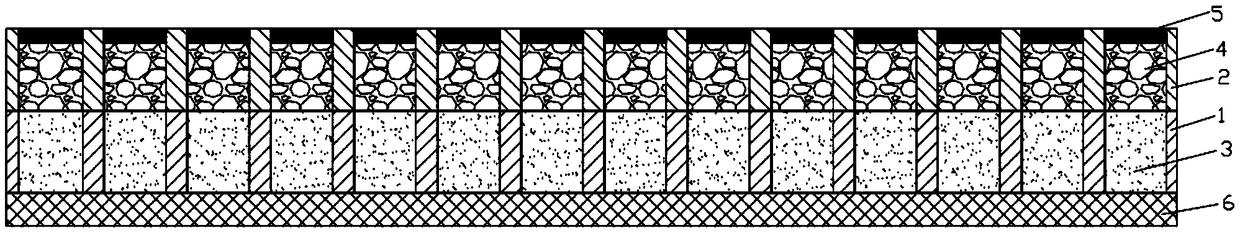

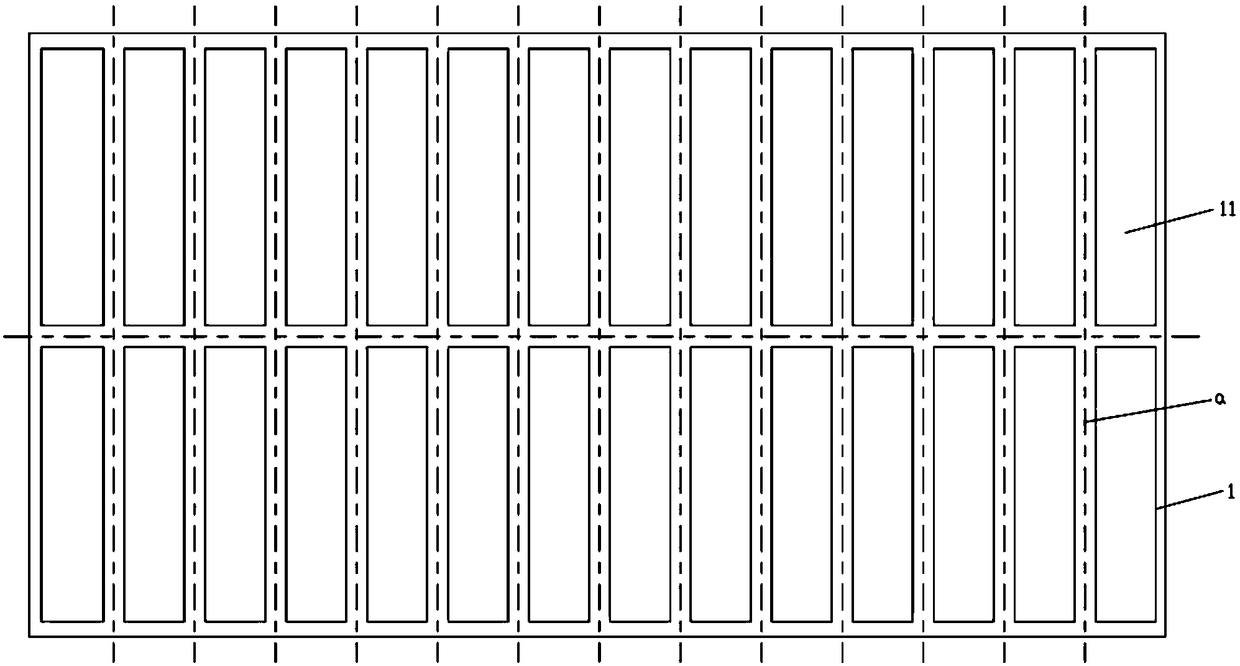

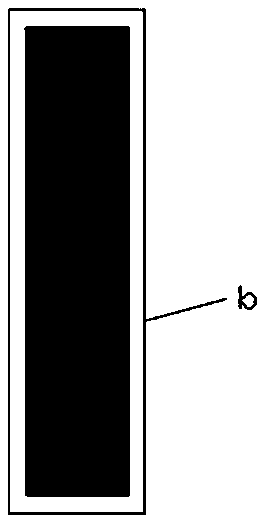

[0034] see Figure 1-2 As shown, a preferred embodiment of the present invention discloses a conductive and heat-conducting foam adhesive tape, including a frame structure, the frame structure has a plurality of evenly distributed grid through holes, and each grid through hole is sequentially arranged from bottom to top. The conductive adhesive layer 3 and foam 4 containing conductive and heat-conducting particles, the bottom end surface of the through hole of the lower grid is provided with a release paper 6 bonded to the conductive adhesive layer 3, and the conductive and heat-conducting ink layer 5 is attached to the foam 4, which is electrically conductive. The top surface of the thermally conductive ink layer 5 is flush with the top surface of the grid through holes.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com