Solid-liquid rocket engine igniter and head wire-outgoing method thereof

A solid-liquid rocket and igniter technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of small installation cable space for flight engines, troublesome wiring of igniter leads, and increased negative mass of engines, etc., to achieve The effect of avoiding wiring on the outer wall, reducing negative mass, and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

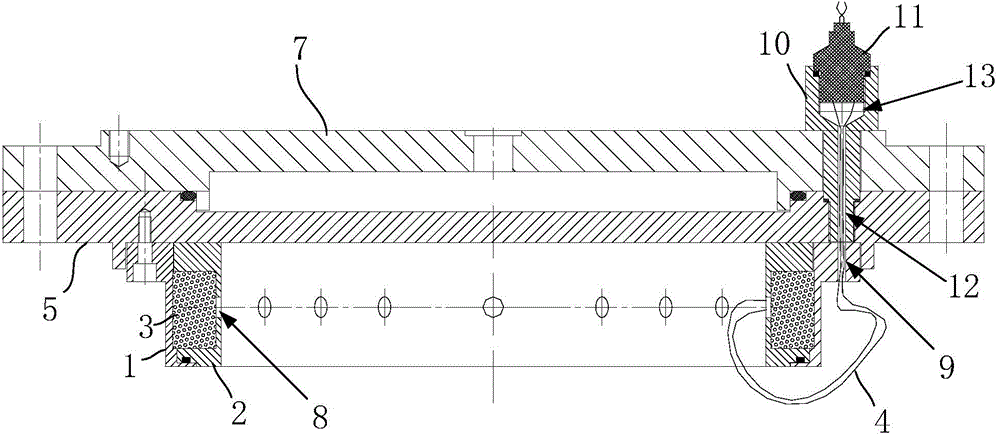

[0030] Below in conjunction with accompanying drawing, the present invention will be further described

[0031] The solid-liquid rocket engine igniter of the present invention comprises an igniter threaded ring 1, an igniter box body 2, and an ignition powder 3, is used for ignition and starting of the solid-liquid rocket engine, and is fixedly installed on the injection panel 5 of the solid-liquid rocket engine. It is located between the injection panel 5 and the grain column 6 .

[0032] Wherein, the threaded ring 1 of the igniter is an annular structure with an internal thread; the igniter box 2 is an annular structure with an external thread, and an annular groove is opened along the circumference of the outer wall of the igniter box 2 . The igniter box body 2 is nested with the igniter threaded ring 1, is located in the igniter threaded ring 1, and is threadedly connected with the external thread on the igniter box body 2 through the internal thread on the igniter threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com