Graphene/cyanate composite material and preparation method and application thereof

A composite material and graphene technology, applied in the field of materials, can solve problems such as damage to graphene structure, decrease in electrical conductivity and thermal conductivity, and achieve the effects of reducing costs, reducing thermal expansion coefficient, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

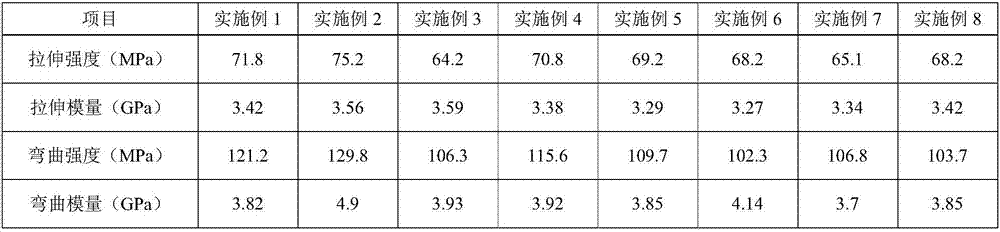

Embodiment 1

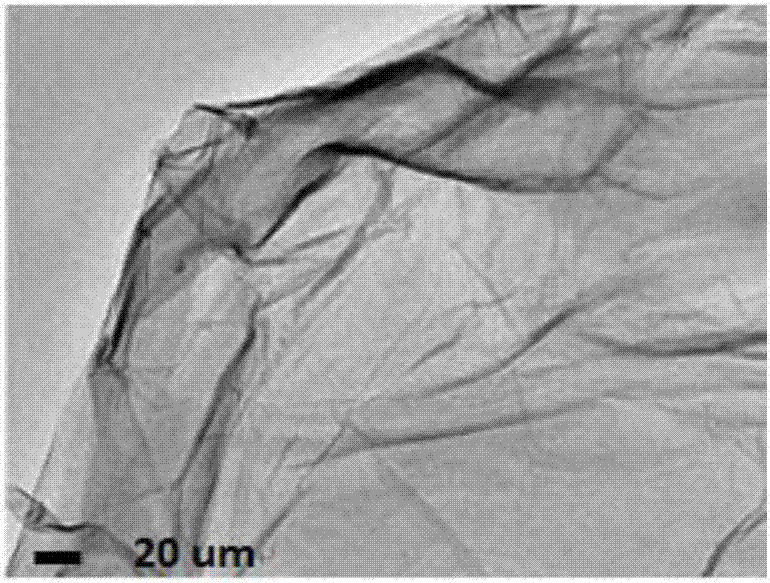

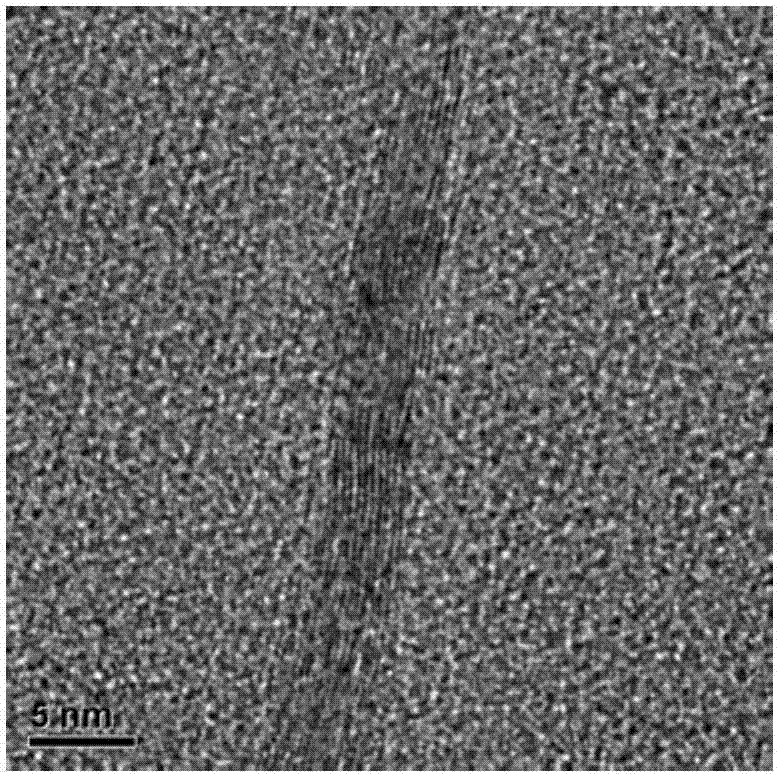

[0044] (1) According to the mass ratio of graphene: graphene microchips: π-π conjugated small molecules: deionized water = 0.5:10:0.5:89, after mixing, use a high-speed mixer and a three-roll mill for pre-dispersion ; Among them π-π conjugated small molecule is 1-pyridine acid succinimidyl ester;

[0045] (2) Place the pre-dispersed aqueous solution in an ice bath environment, use an ultrasonic cell pulverizer to disperse again, use the ultrasonic cell pulverizer to sonicate for 30 minutes at a power of 800W, and then place the obtained dispersion in liquid nitrogen. Cool down quickly, and place it in a freeze dryer after being completely frozen to remove the water to obtain foamed pre-dispersed graphene-graphene microchips;

[0046] (3) Mix the foamed pre-dispersed graphene-graphene microchips with the cyanate ester resin, and then disperse the graphene-graphene microchips in the cyanate ester resin through high-speed stirring and three-roll milling. The mass percentage of pre-di...

Embodiment 2

[0049] (1) Formulated according to the mass ratio of graphene: graphene microchips: π-π conjugated small molecules: deionized water = 1:9:0.5:89.5, after mixing, use a high-speed mixer and a three-roll mill for pre-dispersion ; Among them π-π conjugated small molecule is 1-pyridine acid succinimidyl ester;

[0050] (2) Place the pre-dispersed aqueous solution in an ice bath environment, use an ultrasonic cell pulverizer to disperse again, use the ultrasonic cell pulverizer to sonicate at a power of 500W for 25 minutes, and then place the obtained dispersion in liquid nitrogen. Cool down quickly, and place it in a freeze dryer after being completely frozen to remove the water to obtain foamed pre-dispersed graphene-graphene microchips;

[0051] (3) Mix the foamed pre-dispersed graphene-graphene microchips with the cyanate ester resin, and then disperse the graphene-graphene microchips in the cyanate ester resin through high-speed stirring and three-roll milling. The mass percentage...

Embodiment 3

[0054] (1) According to the mass ratio of graphene: graphene microchips: π-π conjugated small molecules: deionized water = 5:10:1:84, after mixing, use a high-speed mixer and a three-roll mill for pre-dispersion ; Among them π-π conjugated small molecule is 1-pyridine acid succinimidyl ester;

[0055] (2) Place the pre-dispersed aqueous solution in an ice bath environment, use an ultrasonic cell pulverizer to disperse again, use the ultrasonic cell pulverizer to sonicate 40 minutes at a power of 400W, and then place the obtained dispersion in liquid nitrogen. Cool down quickly, and place it in a freeze dryer after being completely frozen to remove the water to obtain foamed pre-dispersed graphene-graphene microchips;

[0056] (3) Mix the foamed pre-dispersed graphene-graphene microchips with the cyanate ester resin, and then disperse the graphene-graphene microchips in the cyanate ester resin through high-speed stirring and three-roll milling. The mass percentage of pre-dispersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com