Three-dimensional swing ball type tuned mass damper

A tuned mass damping and ball-type technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as no vibration damping function of the bracket, damage to precision electronic circuits, collapse of the bracket, and driving safety, etc., to achieve Avoid lightning strikes or conduction, high adaptability, and reduce vertical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

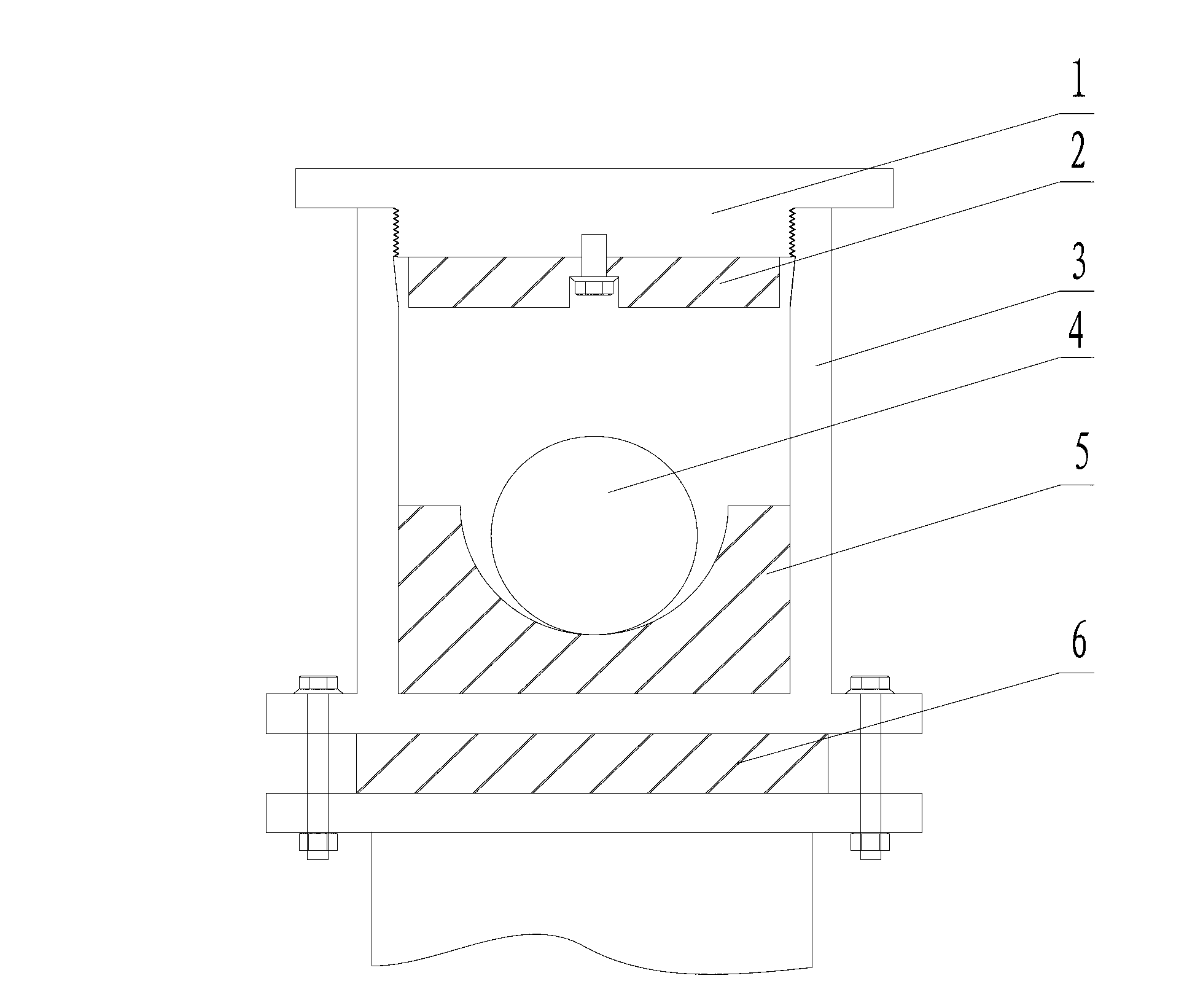

[0019] by figure 1 It can be seen that the three-dimensional pendulum ball type tuned mass damper of this embodiment is formed by connecting the top cover 1, the buffer layer 2, the protective tube 3, the pendulum ball 4, the rubber spherical base 5, and the buffer pad 6.

[0020] In this embodiment, the protective cylinder 3 is a cylindrical shape with an open upper end and a bottom plate at the lower end. The insulating cylinder made of epoxy resin has good stability and high durability.

[0021] The upper end of the protective cylinder 3 is covered with a connecting top cover 1 made of epoxy resin, and screw holes are machined on the connecting top cover 1 to facilitate the installation of precision equipment through threaded fasteners and the connecting top cover 1 can close the protective cylinder. 3. The diameter of the upper end of the connecting cap 1 is larger than the diameter of the lower end, and the lower end of the connecting cap 1 is processed with external threads, ...

Embodiment 2

[0025] In this embodiment, a hemispherical groove is machined on the center of the top surface of the rubber spherical base 5. The radius of the spherical groove is 6cm, the minimum thickness of the spherical base is 1cm, and a pendulum is arranged in the spherical groove. The ball 4 and the pendulum ball 4 are steel balls with a geometric shape of a round ball, with a radius of 5 cm, which is smaller than the radius of the spherical groove. The other components and their connection relationship are the same as in the first embodiment.

Embodiment 3

[0027] In this embodiment, a hemispherical groove is machined on the center of the top surface of the rubber spherical base 5. The radius of the spherical groove is 7.5 cm, the minimum thickness of the spherical base is 2.5 cm, and the spherical groove is provided with A pendulum ball 4, the pendulum ball 4 is a steel ball with a geometric shape of a round ball, with a radius of 5 cm, which is smaller than the radius of the spherical groove. The other components and their connection relationship are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com