Bidirectional-waterstop and vibration-damping elastic water seal device of down-the-hole planar gate

A technology of planar gates and water sealing devices, applied in water conservancy projects, barrage/weirs, sea area engineering, etc., can solve the problems of ineffective water stop, difficult maintenance of water sealing structure, uneconomical, etc., and achieve novel structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

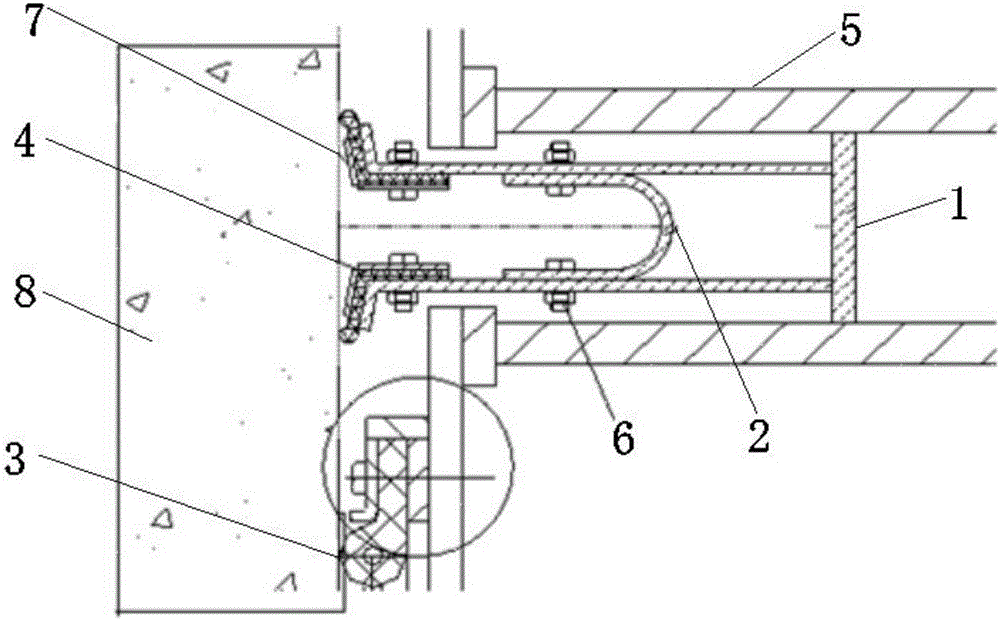

[0025] see figure 1 , the present invention provides a technical solution: an elastic water seal device for two-way water stop and vibration reduction of submersible plane gates, including structural steel 1, spring steel 2, P-shaped water seal 3 and water stop rubber 4, and structural steel 1 is fixed Set between the gate body 5, the inner side of the structural steel 1 is fixed with a spring steel 2, the spring steel 2 and the structural steel 1 are fixedly connected by bolts 6, one end of the structural steel 1 is provided with a water-stop rubber 4, and the outer side of the water-stop rubber 4 is provided with Backing plate 7, backing plate 7 is arranged on one side of door slot 8, and P-type water seal 3 is also arranged between gate body 5 and door slot 8.

[0026] In this embodiment, the shape of the spring steel 2 is a semicircle.

[0027] In this embodiment, the structure adjusts the extrusion degree between the water seal and the door slot through the deformation o...

Embodiment 2

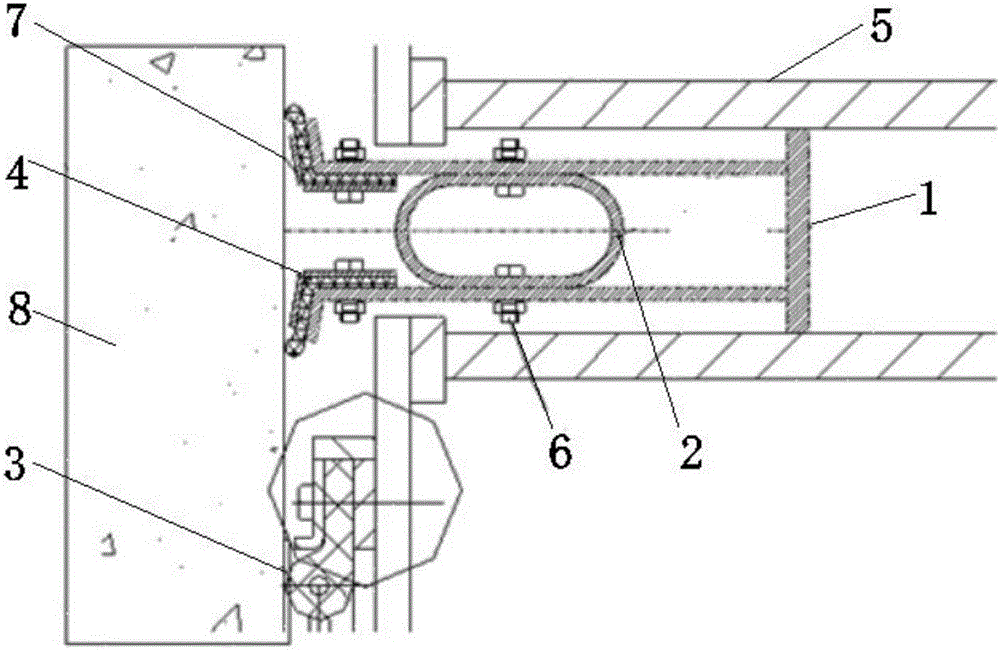

[0029] The difference between this embodiment and the first embodiment is that the shape of the spring steel 2 is elliptical, and the semicircular spring steel in the first embodiment is open, and the cavity between the upper and lower water-stop rubbers may be filled with water. Since the incompressibility of the water body itself limits the deformation of the spring steel, thereby affecting the effect of the elastic water seal, the structure adopted in this embodiment can achieve the purpose of improving the effect of the elastic water seal.

Embodiment 3

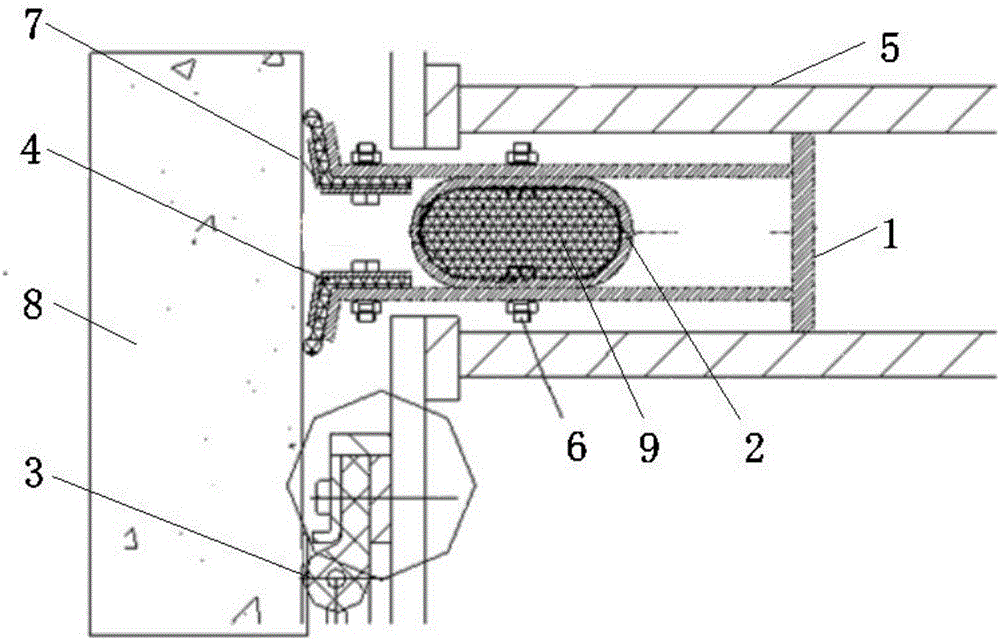

[0031] The difference between the present embodiment and the second embodiment is: it also includes a viscoelastic material 9, the space inside the spring steel 2 filled with the viscoelastic material 9 adopts a fully sealed structure, and the filling volume of the viscoelastic material 9 accounts for 90% of the space volume , The viscoelastic material 9 consists of 50-70 parts of bromobutyl rubber, 10-15 parts of white carbon black, 8-12 parts of stearic acid, 4-8 parts of mica, 7-15 parts of vulcanized resin, and 7-15 parts of crosslinking agent It is prepared by mixing 18 parts. Since spring steel can store energy, it cannot consume energy by itself. A part of the energy transferred to spring steel by the gate body and water flow cannot be dissipated in a short time. Therefore, viscoelastic damping material is filled inside the closed spring steel , dissipating energy directly through the damping material.

[0032] The using method of the present invention comprises the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com