Iridium-tungsten alloy nano-material, preparation method thereof and application of iridium-tungsten alloy nano-material as acidic oxygen evolution reaction electrocatalyst

A nanomaterial, tungsten alloy technology, applied in nanotechnology, nanotechnology, metal processing equipment, etc., can solve problems such as poor activity, high price, and unfavorable large-scale development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

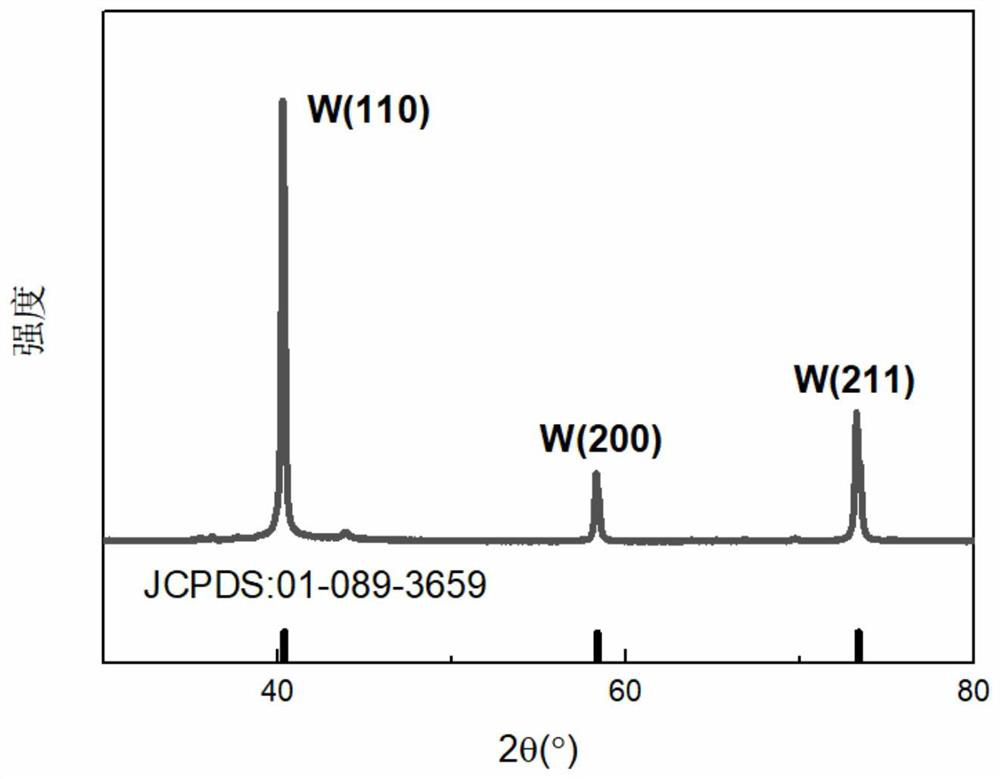

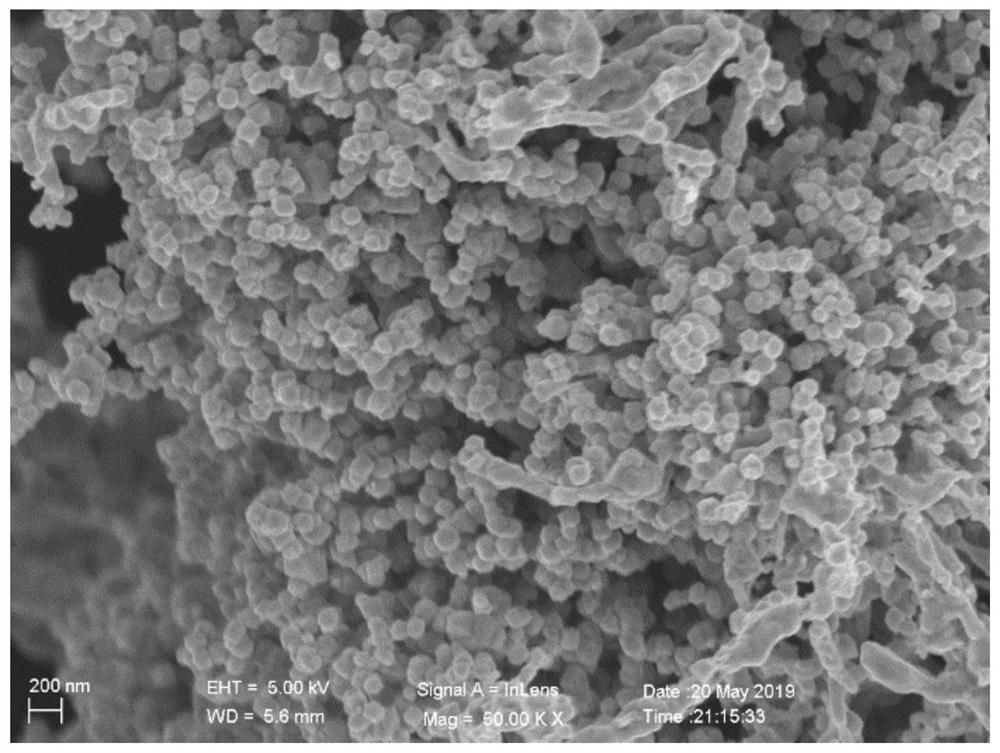

[0035] Preparation of IrW alloy nanomaterials:

[0036] Weigh 4.123g of sodium tungstate dihydrate and 4.41g of oxalic acid, stir and dissolve in 100ml of water, add 1mol / L dilute sulfuric acid drop by drop and check with acidic precision pH test paper, adjust the pH to 3.2, and use it as the mother liquor for later use. Take 20ml of mother liquor in a beaker, weigh 1.586g of ammonium sulfate in the mother liquor, stir and dissolve, after the solution is clarified, weigh 0.25g of chloroiridic acid (35% effective content) in the beaker filled with the above solution, stir rapidly until thoroughly dissolved, the solution was brown and transparent. Transfer the brown solution into a 25ml polytetrafluoroethylene hydrothermal reaction kettle, take a 2cm×2cm hydrophilic carbon cloth (soaked with concentrated sulfuric acid and concentrated nitric acid for one week in advance) and place it in the reaction kettle, making it lean against the container The wall remains vertical. Put it...

Embodiment 2-4

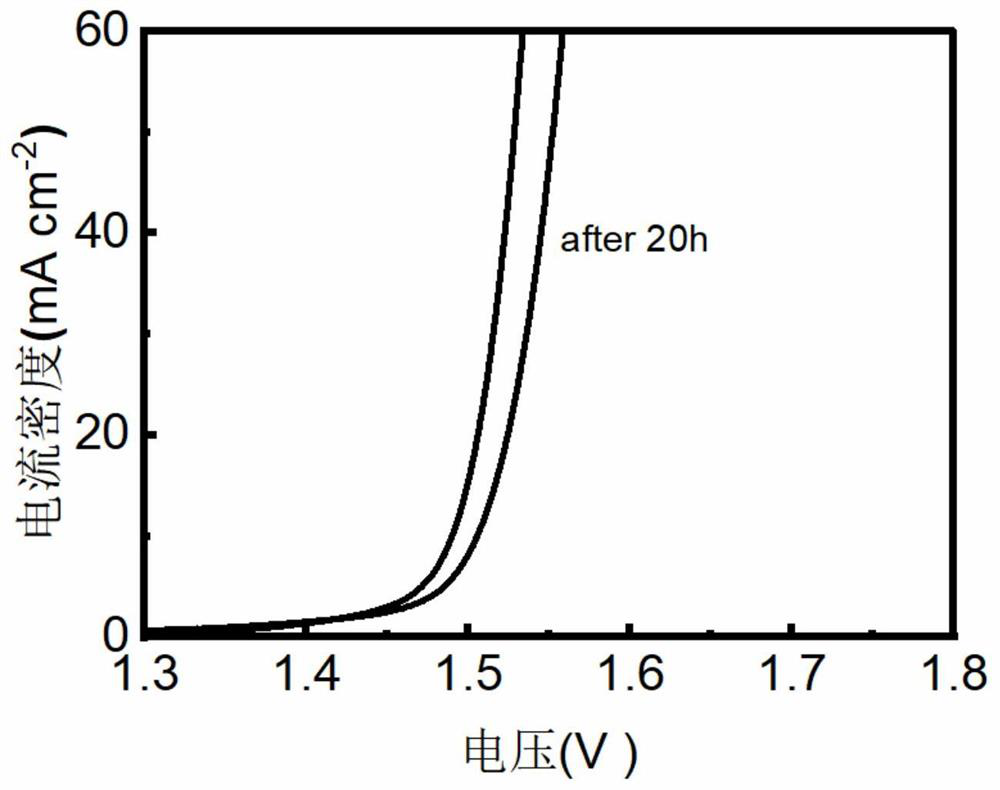

[0051] Only the amount of Ir source added (as shown in Table 1) was changed, and the rest of the conditions were the same as in Example 1. The OER catalytic performance is shown in Table 1.

[0052] The comparison of different examples shows that when the content of Ir is 7wt%, the catalyst activity reaches the optimum, and the catalytic performance will not increase significantly if the content of Ir is continued to increase.

[0053] The input amount and electrochemical performance summary table of Ir among the table 1 embodiment 1~4

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com