Heating device, film forming apparatus, film forming method, and device

A heating device and mounting technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, gaseous chemical plating, etc., can solve the problems of unfree expansion of the device, poor coverage, and inability to apply large substrates such as glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

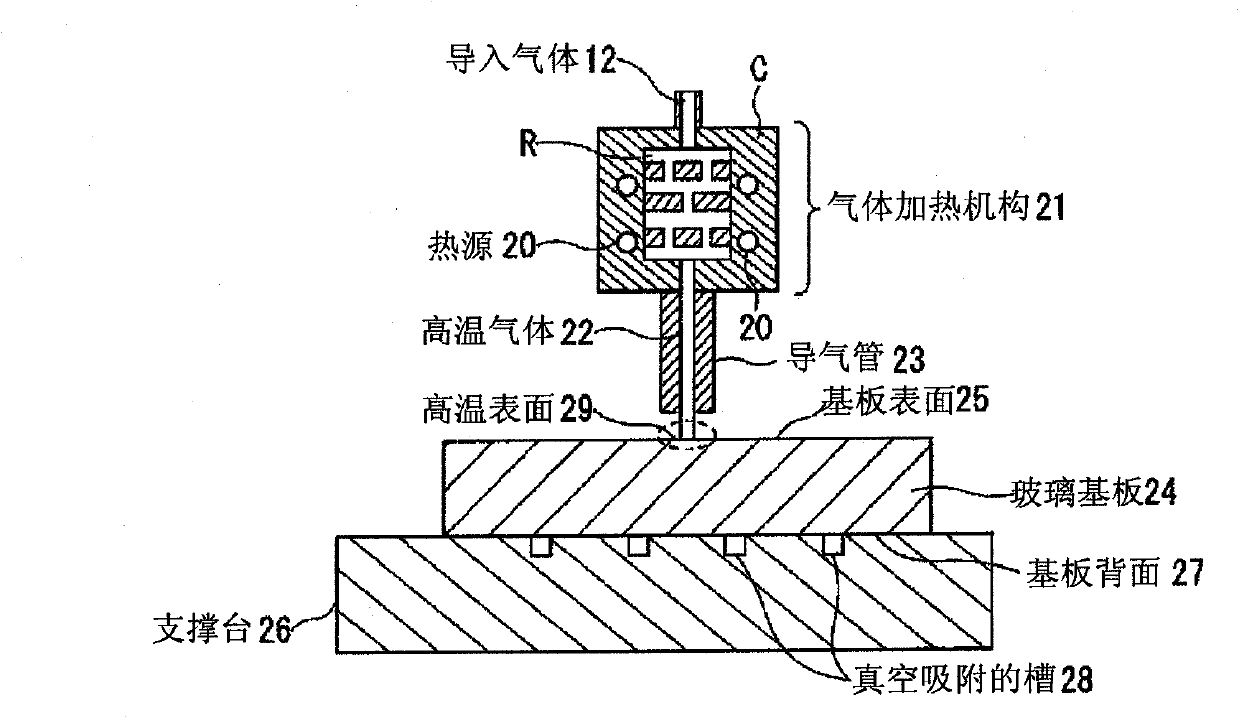

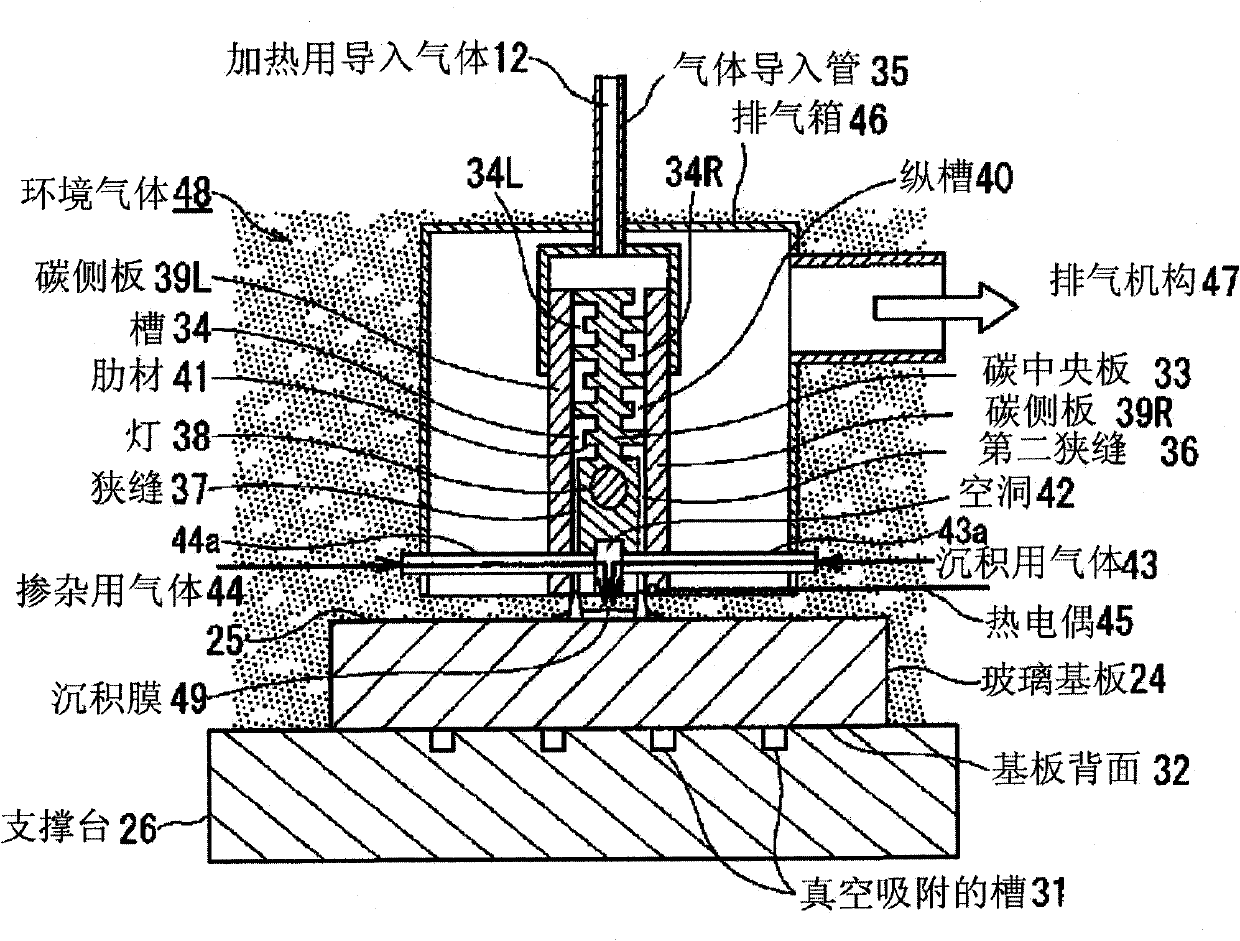

[0115] figure 2 Indicates that it has the same as the figure 1 The shown heating device is a schematic cross-sectional view of a film forming apparatus configured by a heating device based on substantially the same principle. Such as figure 2 As shown, the glass substrate 24 has a thickness of, for example, 0.7 mm, and is tightly placed on the glass substrate supporting table 26 . The support table 26 has a vacuum suction tank 31 therein, which absorbs the glass substrate 24 to effectively make thermal contact, and the temperature of the support table 26 is used to control the temperature of the back surface 32 of the glass substrate 34 .

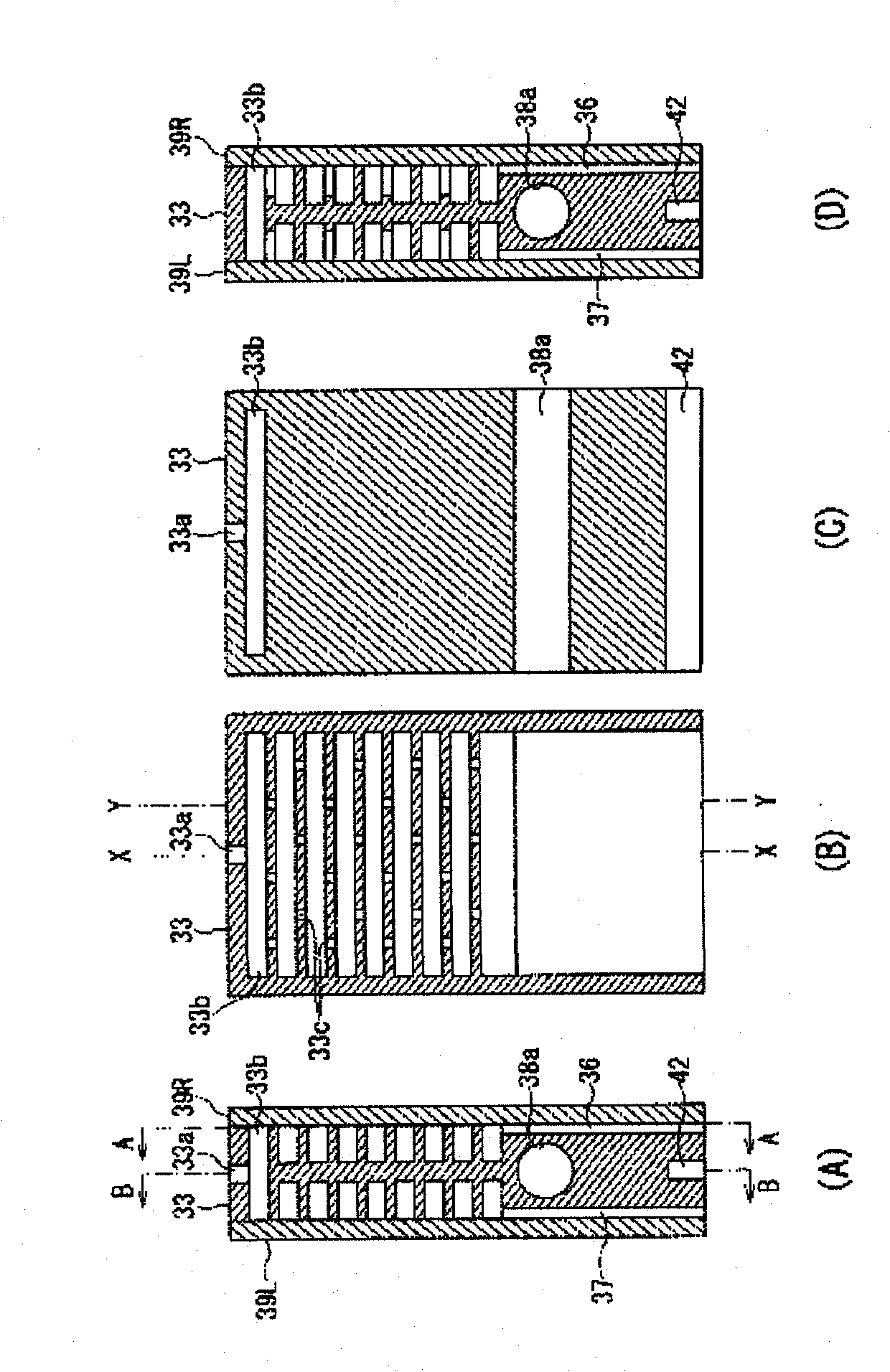

[0116] The heating mechanism of the introduced gas 12 for heating will be described. The heating mechanism has: a solid flat carbon central plate 33 formed of carbon (including, for example, graphite, isotropic carbon, etc.) A pair of left and right carbon side plates 39L, 39R, in the depth direction of the carbon central plate 33 ( ...

no. 2 approach

[0135] Figure 7 is a configuration diagram showing the configuration of the film forming apparatus 111 according to the second embodiment of the present invention, Figure 8 It is an enlarged view of its main part.

[0136] Such as Figure 7 As shown, the film forming apparatus 111 has: a substrate 112 for forming a desired film; a coolable and movable support table 113 supporting the substrate 112 ; and a gas blowing device 114 .

[0137] The substrate 112 is formed of a flat glass substrate or plastic substrate of a desired size, and a silicon oxide film or a silicon oxide film is formed on the surface 112a at a temperature higher than the softening temperature of these substrates 112 (for example, 300°C to 400°C). Films of high-temperature thermal CVD materials such as silicon nitride films and polysilicon are grown.

[0138] The support table 113 is formed on the surface 113a that is in close contact with the back surface 112b of the substrate 112. A plurality of groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com