Chemical nickel plating device and chemical nickel plating method

A technology of electroless nickel plating and electroless nickel plating solution, applied in the field of electroless nickel plating, can solve problems such as poor thermal conductivity and strength of the tank body, increase the cost of electroless nickel plating, etc., achieve bright plating, avoid poor thermal conductivity of the tank body, and stabilize the solution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

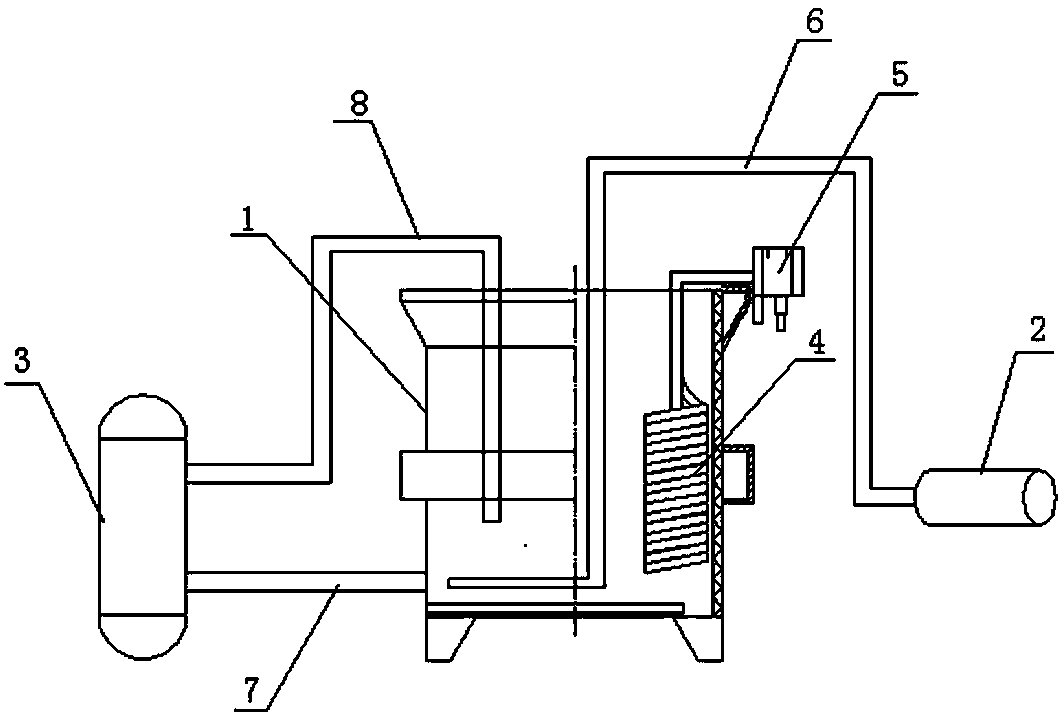

[0016] like figure 1 Shown, a kind of electroless nickel plating device comprises tank body 1, air compressor 2 and circulation filter 3, tank body 1 is cuboid shape, is provided with electric heating tube 4 in tank body 1, and electric heating tube 4 is arranged on The temperature controller 5 outside the tank body 1 is connected, the air compressor 2 is connected with an air pipe 6, and the end of the air pipe 6 extends into the bottom of the tank body 1, and the airflow generated by the air compressor 2 passes through the air pipe 6 into the tank body 1 bottom, the electroless nickel plating liquid in tank body 1 is constantly stirred; Circulation filter 3 is existing structure, mainly is made of pump, filter, frame, valve and pipeline, and the two ends of circulation filter 3 are connected with The liquid inlet pipe 7 and the liquid outlet pipe 8, the liquid inlet pipe 7 is connected with the bottom of the tank body 1, the liquid outlet pipe 8 extends into the tank body 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com