Device and method for coating inner wall of pipe

A technology for the inner wall of the tube and the inner electrode, which is used in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as complex structure, and achieve the effect of high deposition rate, low vacuum system requirements, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions and beneficial effects of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

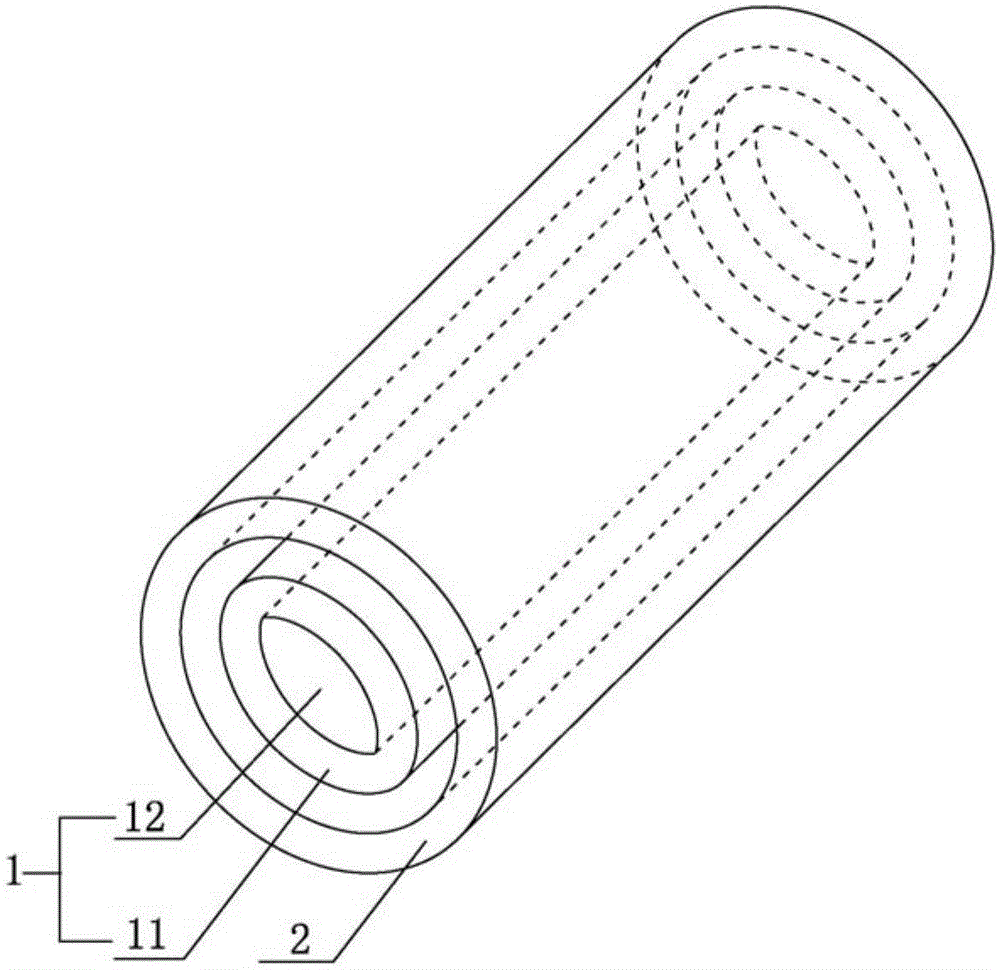

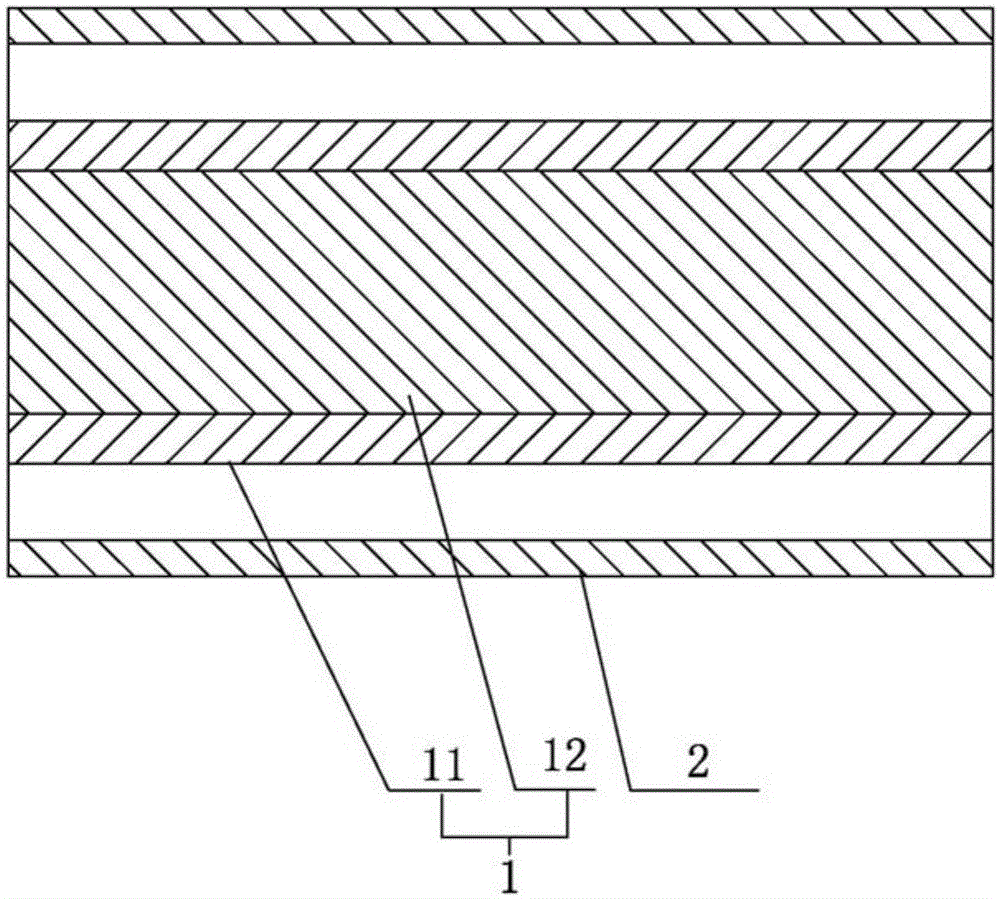

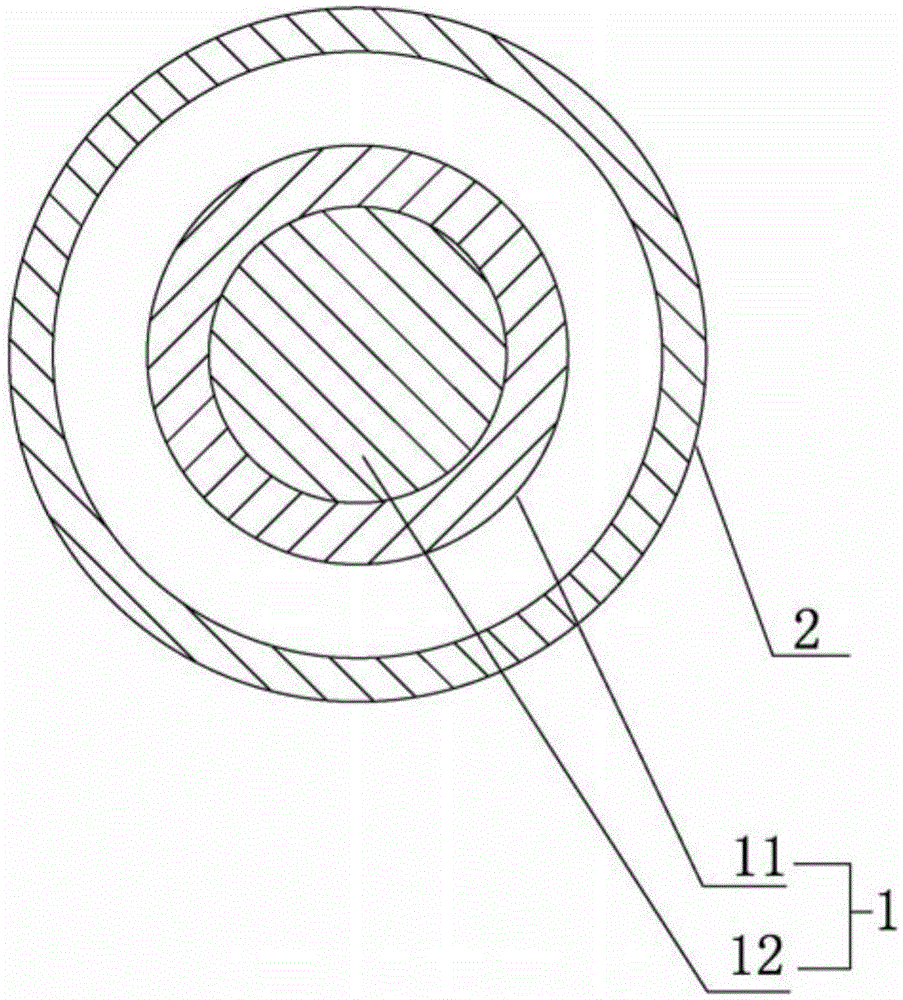

[0026] The device for tube inner wall coating of the present invention includes a power supply and an inner electrode 1 that can be inserted into the tube 2 to be plated. The inner electrode 1 has a double-layer structure, the inner layer is a conductor 11, and the outer layer is a dielectric layer 12. Next, the inner electrode 1 is set in the tube 2 to be plated and connected to the power supply. The tube 2 to be plated is made of a conductive material and is also connected to the power source. In the energized state, a dielectric barrier discharge is generated between the inner electrode 1 and the tube 2 to be plated. , to excite the gas raw material to generate plasma to realize thin film deposition.

[0027] The device for coating the inner wall of a pipe of the present invention is applicab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com