Portable ultrasonic auxiliary spark sedimentation repairing and polishing integrated device and process thereof

An electric spark deposition, ultrasonic-assisted technology, applied in the direction of manufacturing tools, arc welding equipment, metal processing equipment, etc., can solve the problems of inability to obtain a large repair thickness deposition layer, limit promotion, etc., to prevent electrode bonding and widen repair The effect of domain and organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

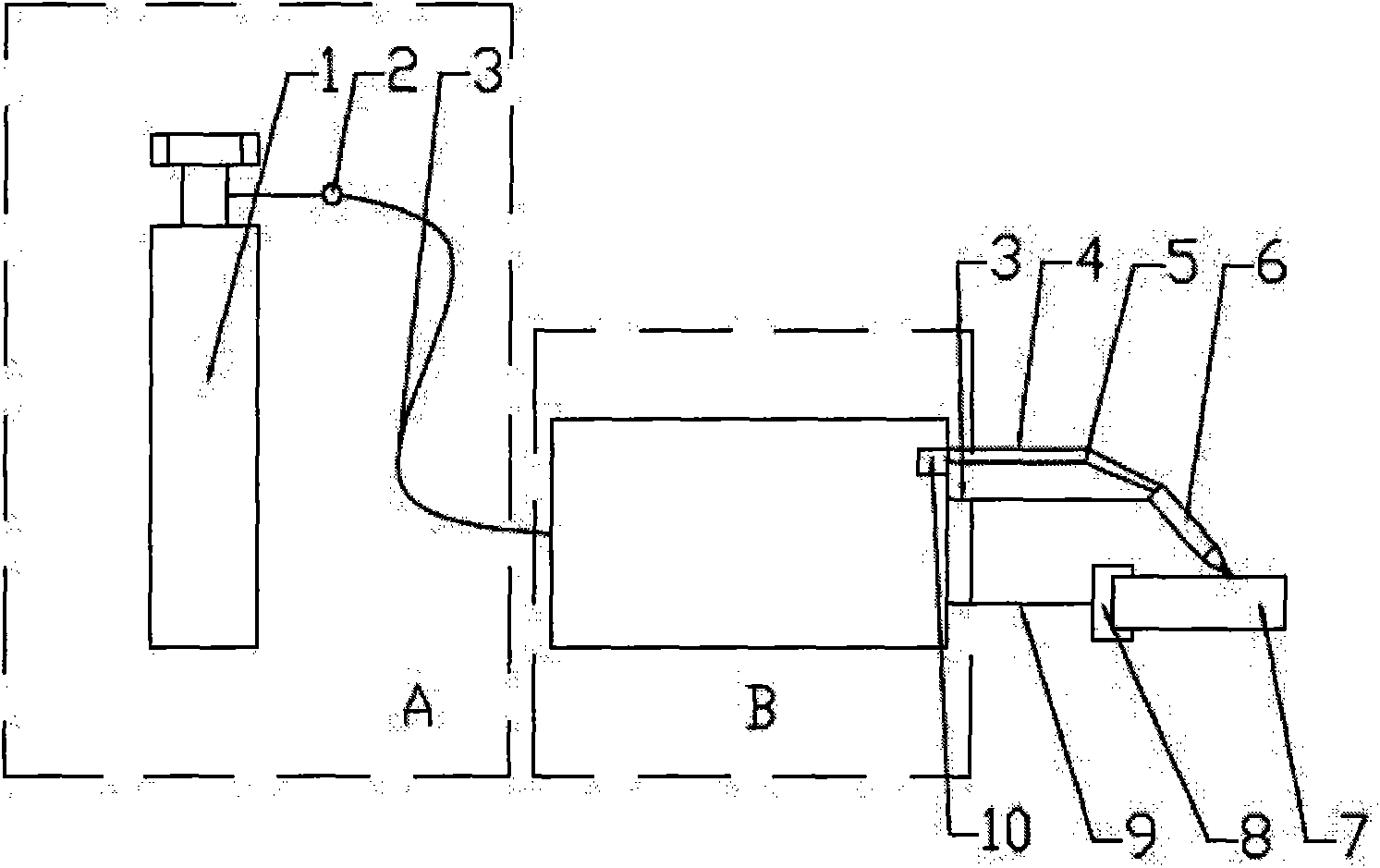

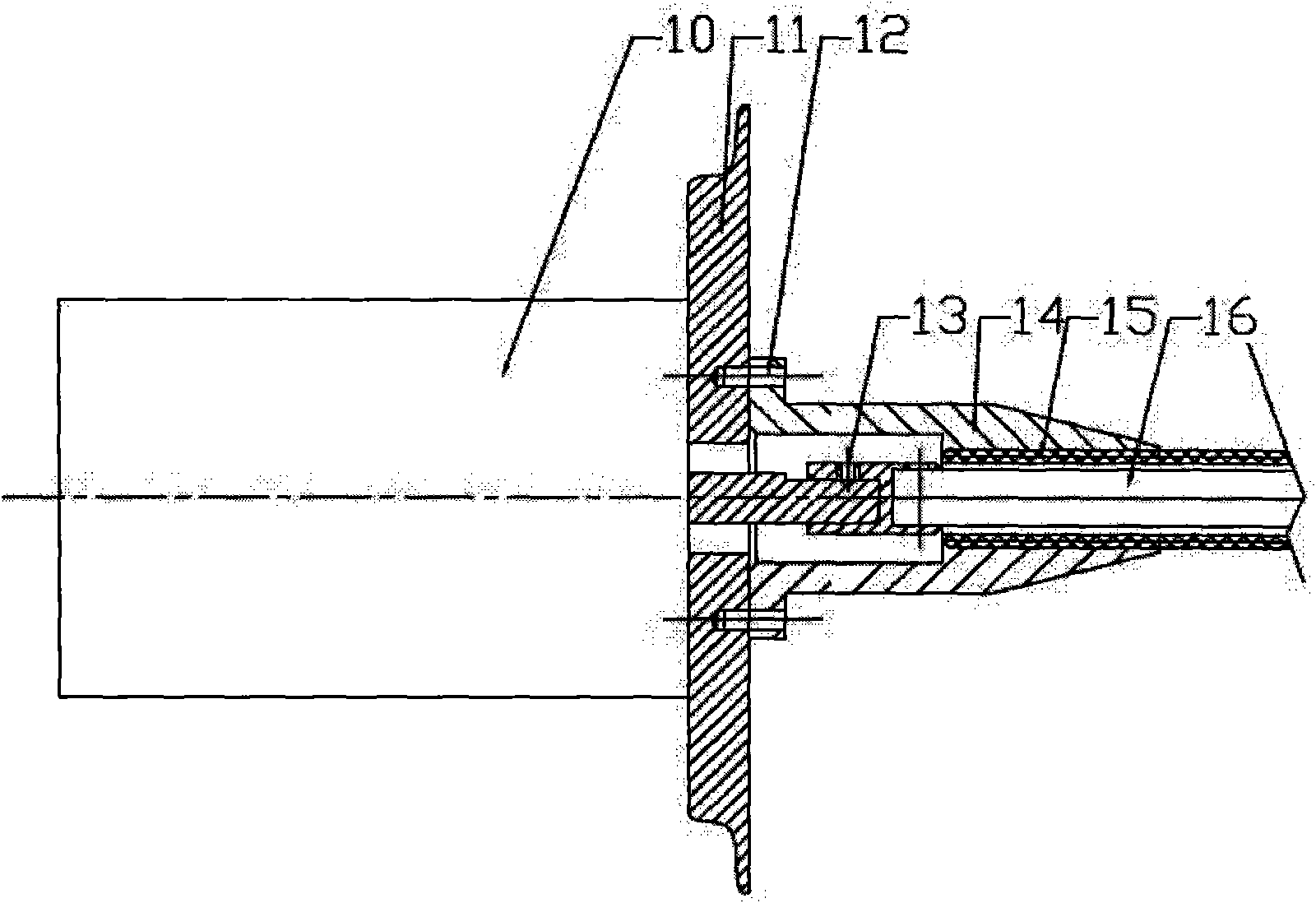

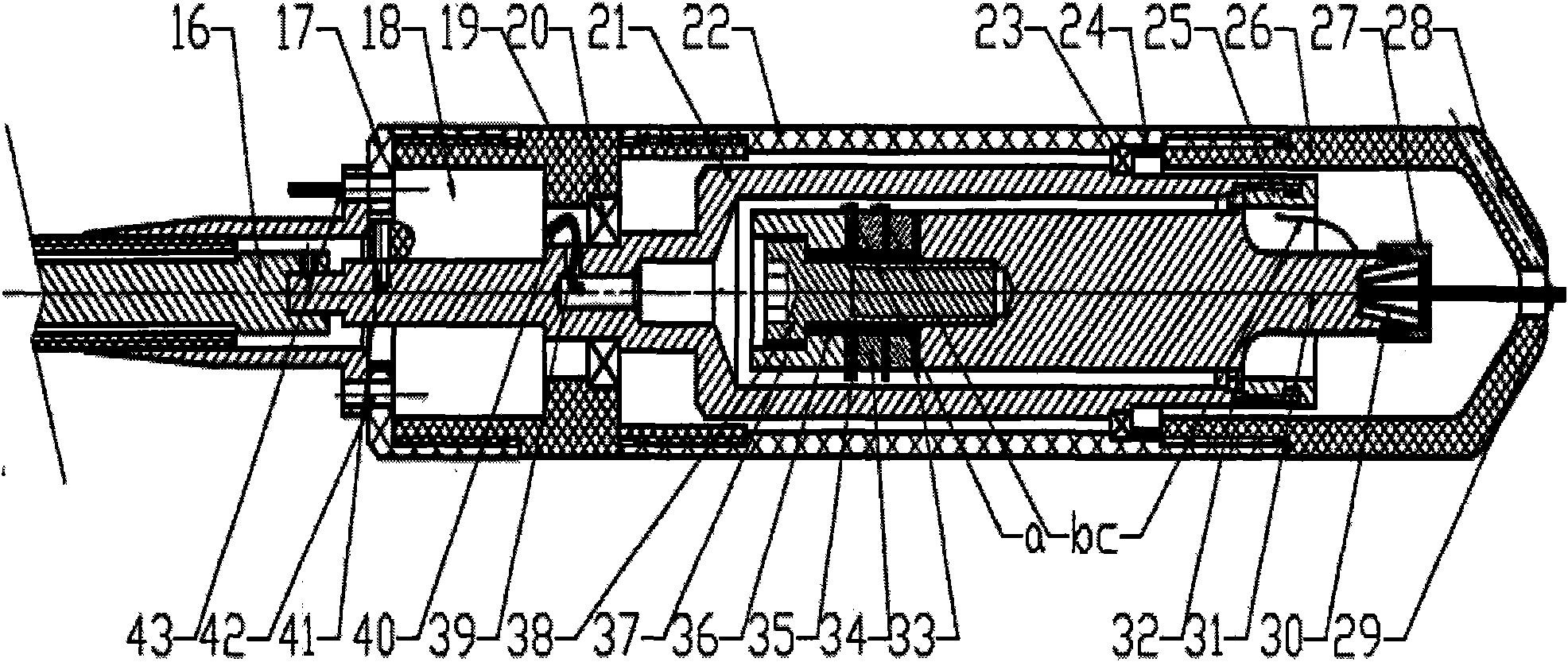

[0040] The structure diagram of the present invention is as figure 1 , 2 , 3, and 4, the portable ultrasonic-assisted EDM deposition repair and polishing integrated device of the present invention includes a gas supply system A, a power supply and a control box B, a wiring system 4, and an ultrasonic-assisted EDM deposition repair and polishing integrated body 6, workpiece chuck 8, tool electrode 29, wherein the ultrasonic assisted EDM deposition repair and polishing integrated body 6 includes a housing, a spindle 21 and an ultrasonic vibrator, and the ultrasonic vibrator includes a rear matching cover 37, The two electrode pieces 35 of the ultrasonic vibrator, the piezoelectric ceramic 34 placed between the two electrode pieces 35 and the other piezoelectric ceramic 34 placed between one of the electrode pieces 35 and the insulating piece 33, the insulating sleeve 36, and the horn 31. Prestressed screw 38, collet 30, wherein the insulating sleeve 36 is set on the outside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com