Device and method for manufacturing micro-nano structure

A technology of micro-nano structure and manufacturing device, applied in the fields of nano-structure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of complex operation, expensive equipment, limited processing accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

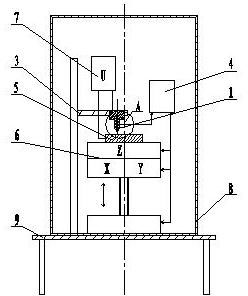

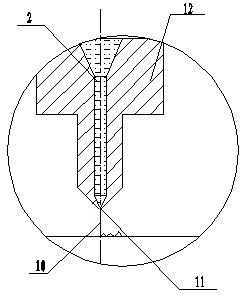

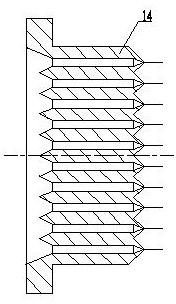

[0024] A micro-nano structure manufacturing device of the present invention, such as Figure 1~2 The schematic diagram shown mainly includes a ball pen 1, a plating solution 2, a ball pen stand 3, an atomic force microscopic detection system 4, a cathode platform 5, a micro-motion workbench 6, and a micro-electric power supply 7, in which the ball pen containing the plating solution 1 is fixed on the atomic pen stand 3 to support the atomic pen 1, the atomic pen stand 3 is integrated with the atomic force microscopic detection system 4, and the rough positioning and precise positioning are performed on it, and the cathode platform 5 is fixedly connected to the micro-motion workbench 6 , separated by insulating material between the cathode platform 5 and the micro-movement workbench 6, the ball pen refill 10 is connected with the positive pole of the micro-electric power supply 7, and the cathode platform 5 is connected with the negative pole of the micro-electric power supply 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com