Apparatus for simulating insulation ablation under condition of particle deposition in cavity in back wall of submerged nozzle

A technology for simulating devices and internal particles, which is applied in the direction of chemical analysis using combustion to achieve the effect of convenient research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

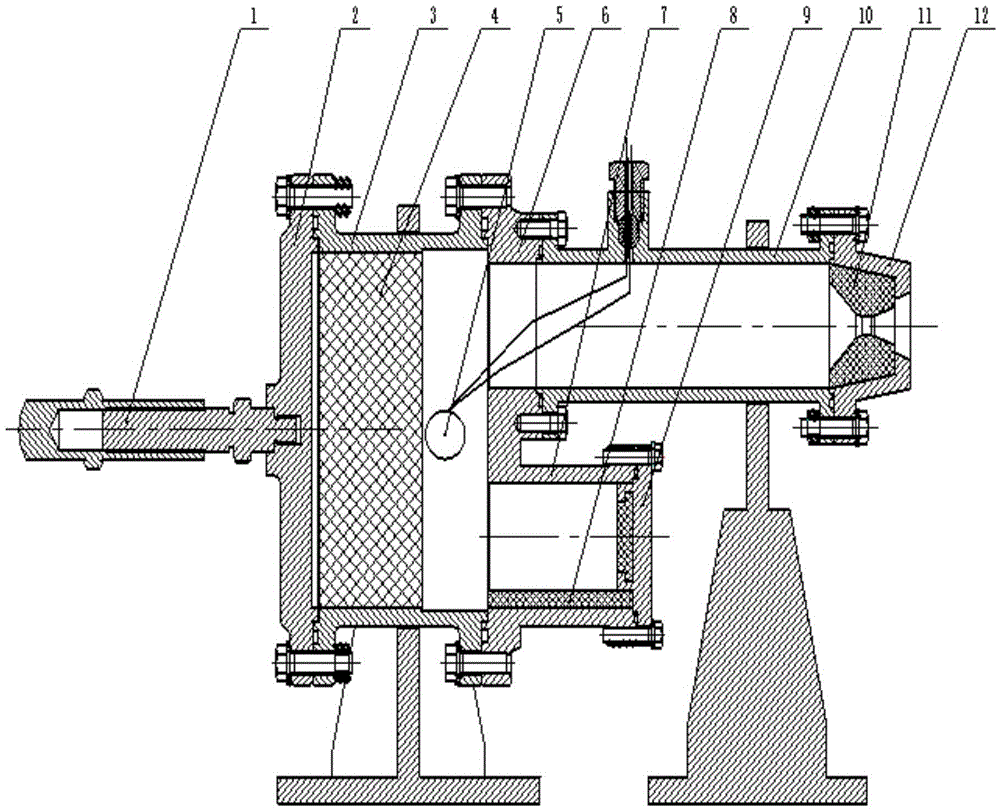

[0033] Embodiment: in the experiment, experimental device of the present invention is according to figure 1 It is assembled as shown, wherein the front head ejector rod 1, the front head 2, the combustion chamber 3, the transition pipe 6, the runner pipe 10, the deposition chamber cover plate 9 and the nozzle gland 12 are all made of 45# steel. Propellant 4, heat insulation layer test piece 8, and nozzle 11 throat diameters are determined by the experimental conditions.

[0034] The front head rod 1 is a two-stage structure with adjustable length, and is connected with the front head 2 by M16*1.5 thread; the combustion chamber 3 is a hollow cylinder with a length of 150mm, an outer diameter of 220mm, an inner diameter of 200mm, and a flange on the end face There are 20 equidistant openings with a diameter of φ13; the two ends of the transition pipe 6 are respectively welded with two circular and square end flanges, and there are 20 equidistant openings on the two end flanges o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com