Quantum dot material structure and its growth method

A technology of quantum dot material and growth method, which is applied in the field of positioning growth and process control of quantum dot materials with low-dimensional semiconductor structures, can solve the problems of unsatisfactory quantum dot position distribution control and affect the photoelectric performance of quantum dots, etc., and achieve simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

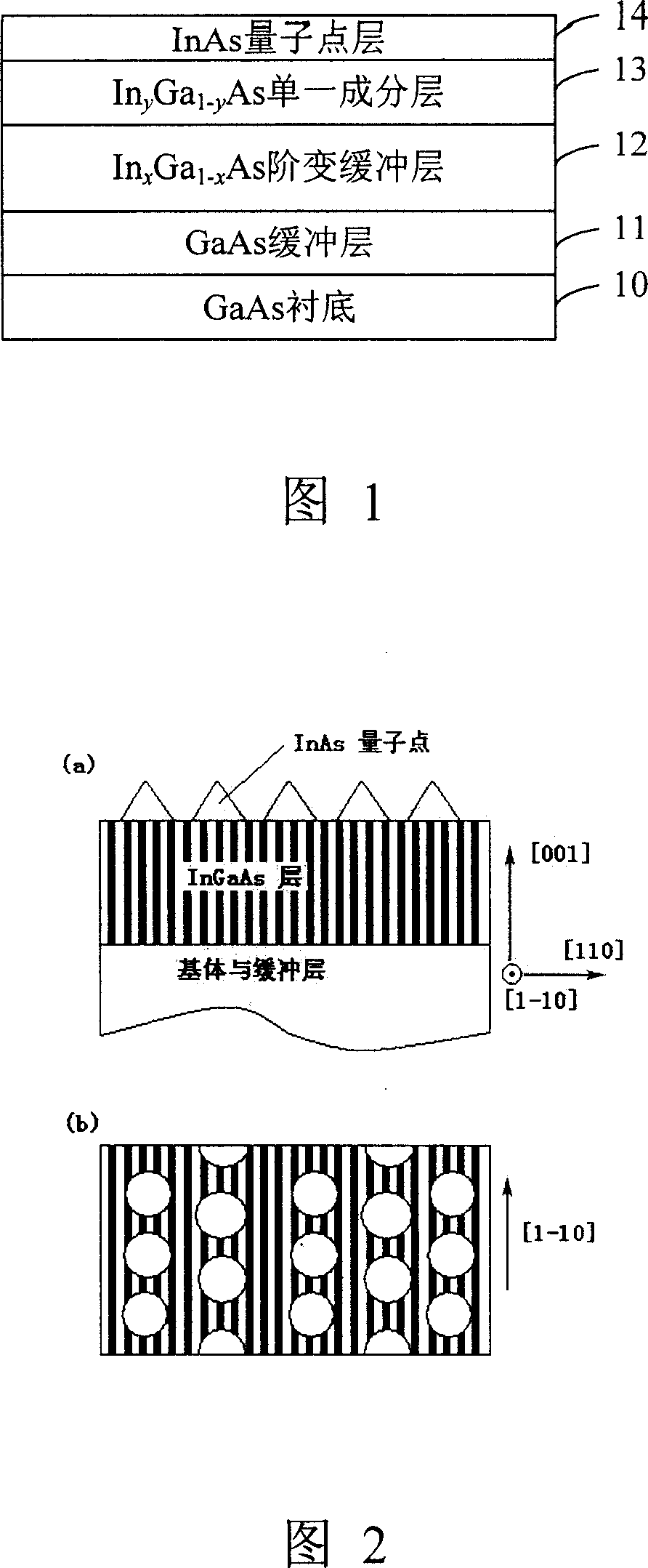

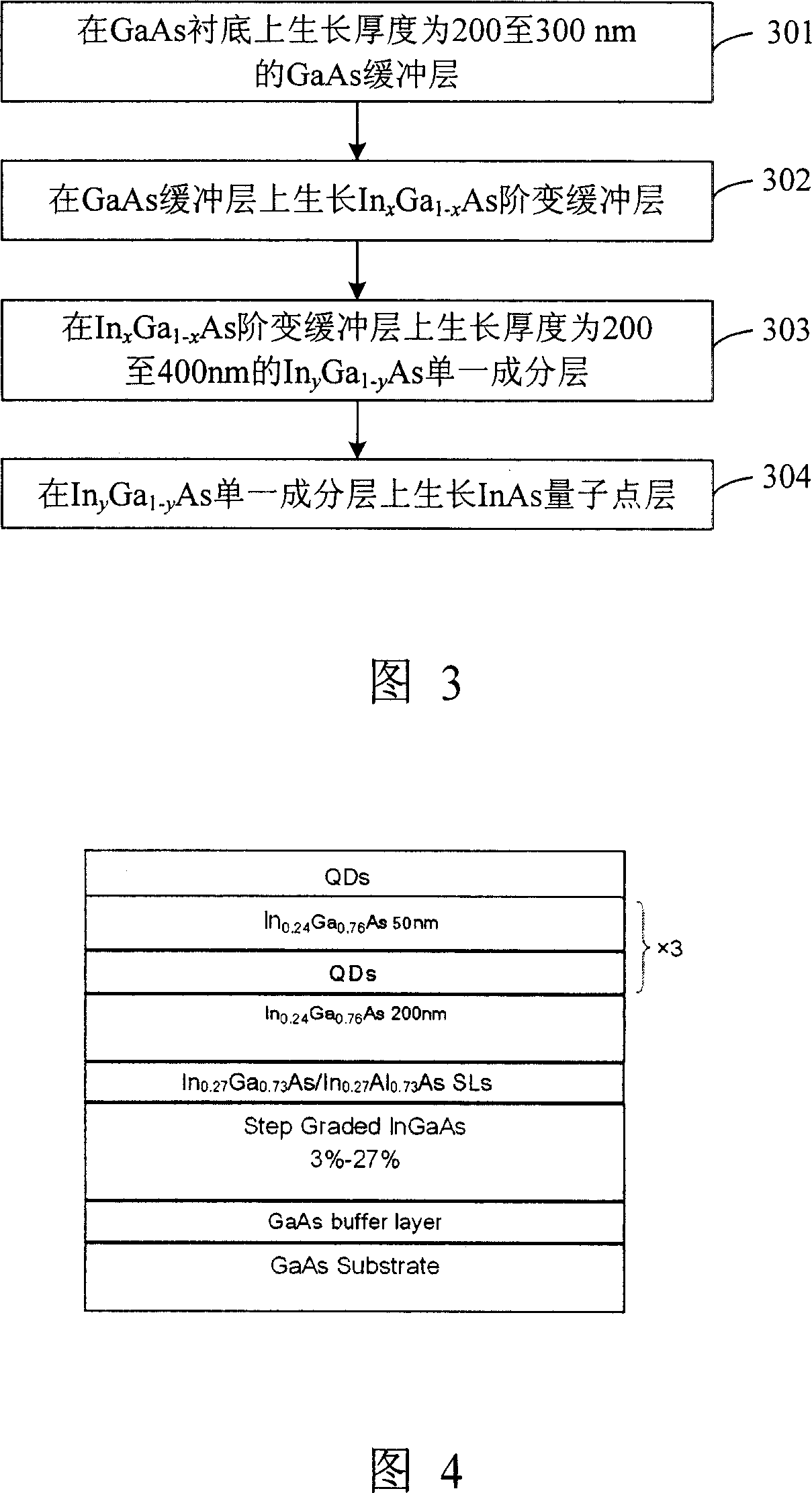

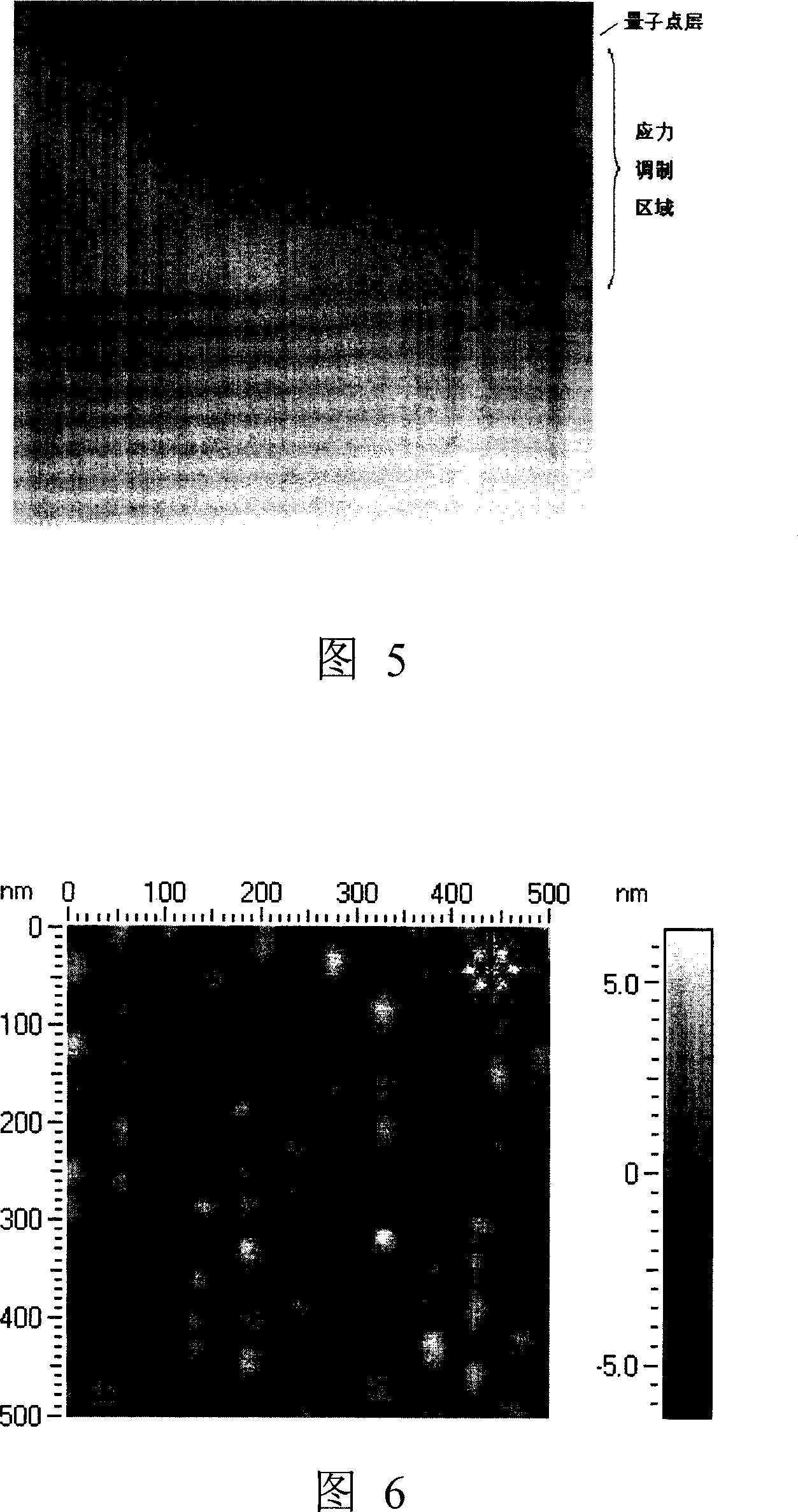

[0071] A 200nm thick GaAs buffer layer was grown on a GaAs (001) substrate with a 2° bias at 600°C, and then the substrate temperature was lowered to 400°C to grow an InGaAs step-change buffer layer. The step-change buffer layer has nine sub-layers, each with a thickness of 100 nm. The In composition changes from the first step's In0.03Ga0.97As to the ninth step's In at an increasing rate of 0.03. 0.27 Ga 0.73 As. Subsequent growth of In for 10 cycles 0.27 Ga 0.73 As(10nm) / In 0.27 Al 0.73 As (10nm) superlattice structure. Then the substrate temperature was increased to 450°C, and 200nm thick In 0.24 Ga 0.76 As layer. The substrate temperature is increased to 500℃, a 2.8ML thick InAs layer is deposited to form quantum dots, and then the temperature is reduced to 450℃ to grow 50nmIn 0.24 Ga 0.76 As spacer layer. The InAs quantum dots and spacer layer structure are repeatedly grown for three cycles, and finally the substrate becomes 500°C grown surface quantum dots with a thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com