Technology of separating dimethyl carbonate from dimethyl carbonate and methanol and water

A technology of dimethyl carbonate and methanol, applied in the field of organic chemical separation, can solve the problems of high energy consumption and equipment cost, lack of economic value, large solvent consumption, etc., and achieves small solvent demand, high operation efficiency, and extraction operation. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

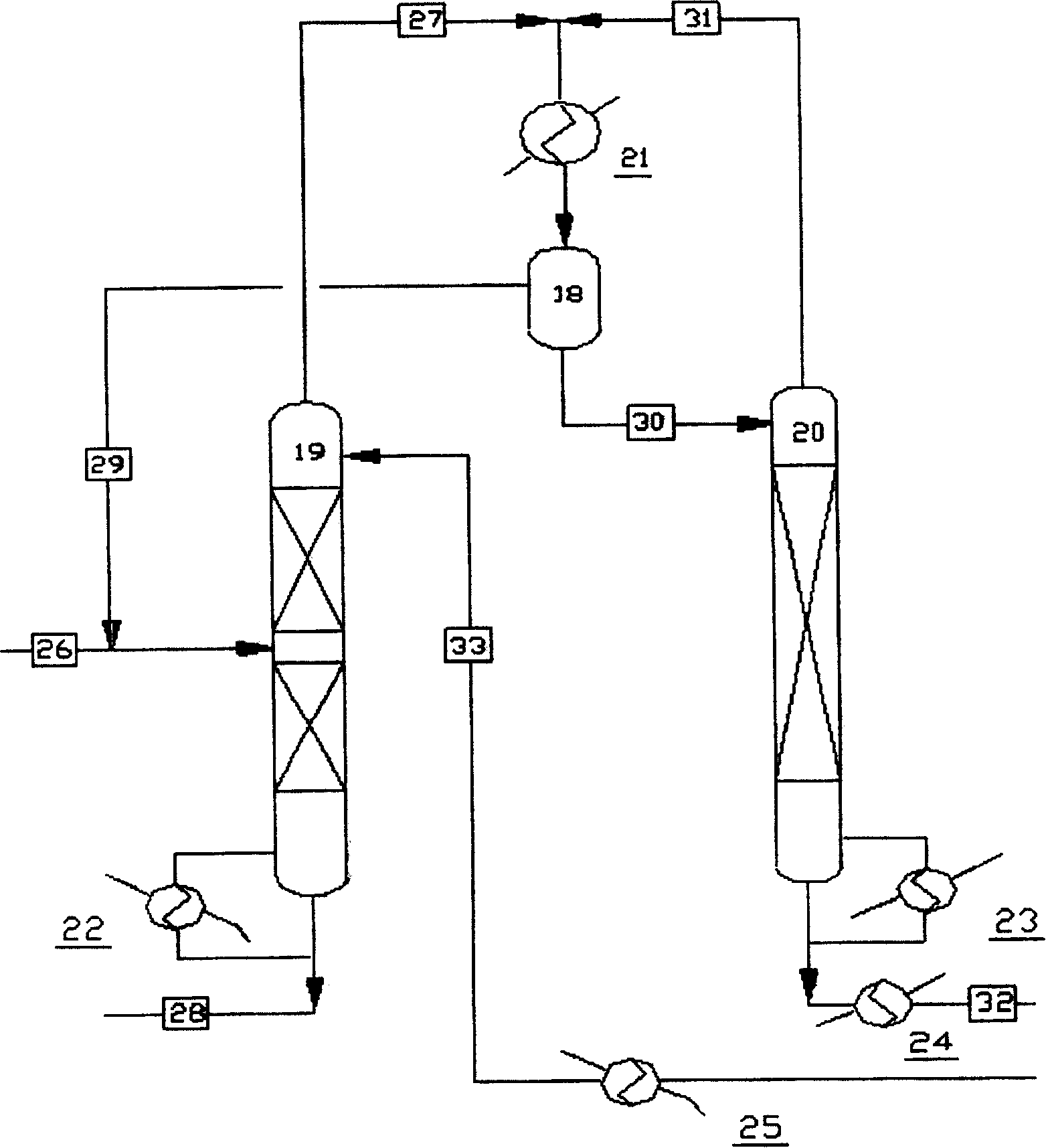

[0035] The experiments were carried out in two rectification columns, an extractor and a stratifier. The rectification tower is a stainless steel packed tower with a tower diameter of 1200mm and a packing (stainless steel corrugated packing) height of 18000mm.

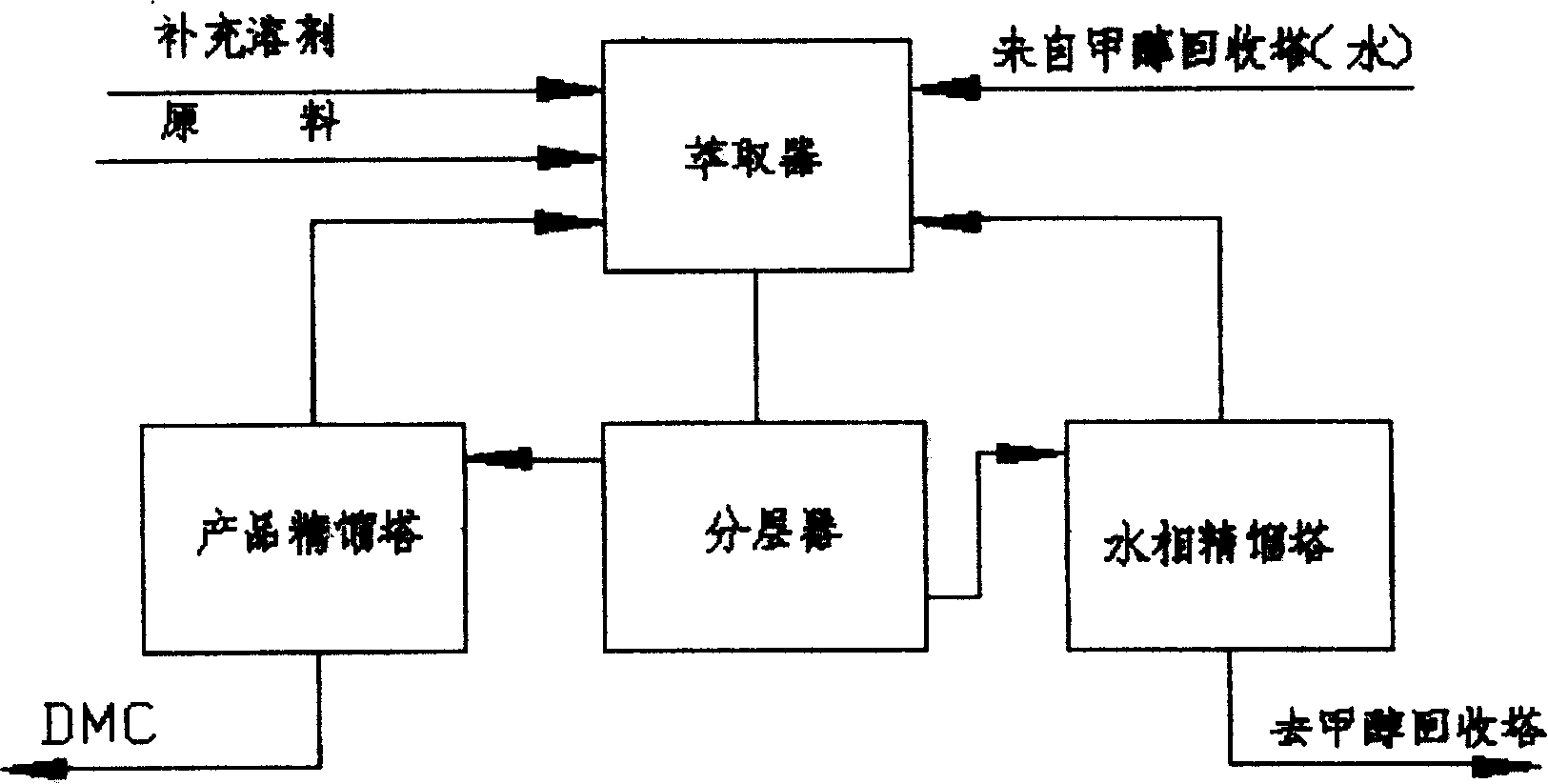

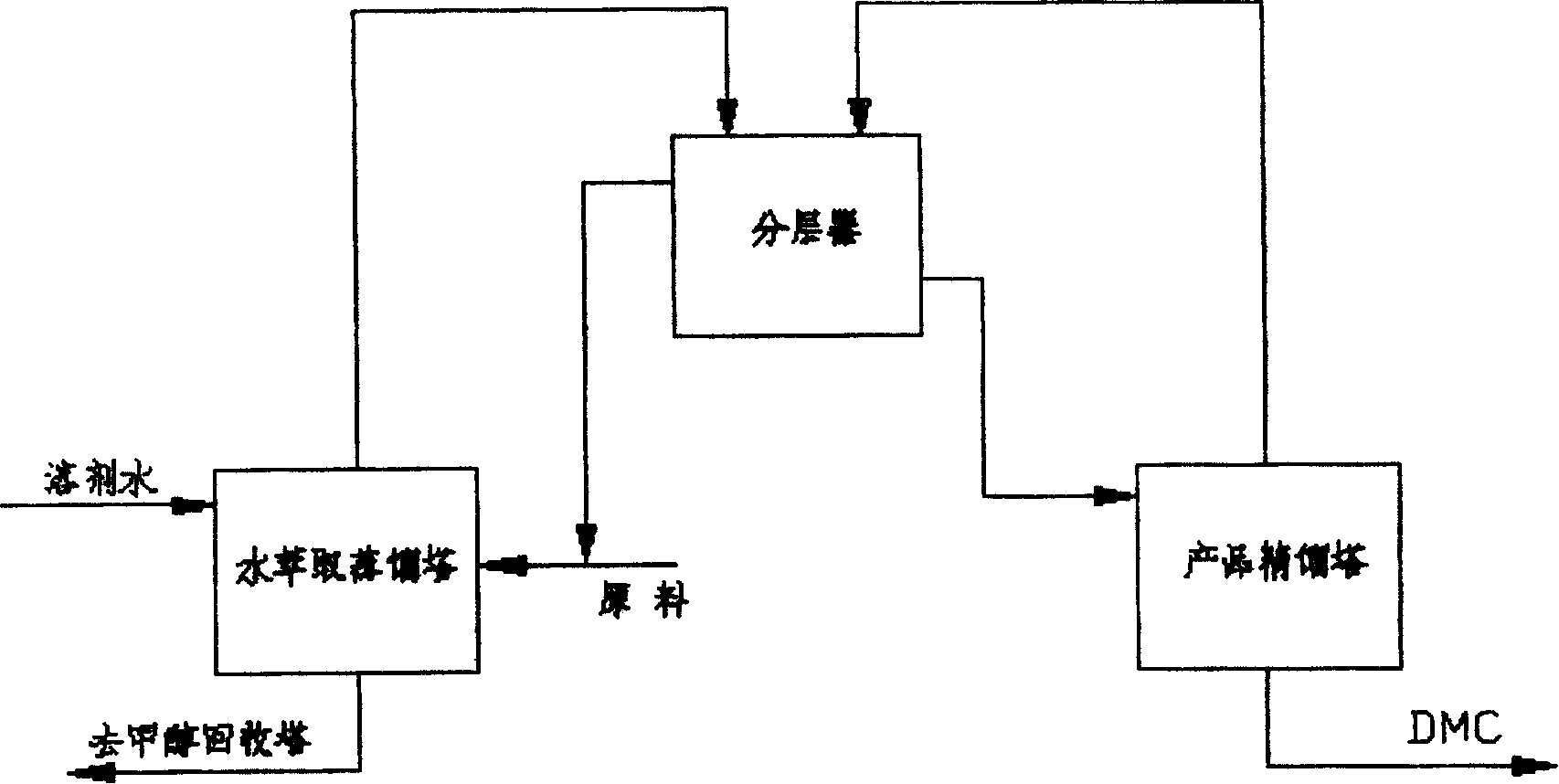

[0036] Raw material liquid 9 (containing a small amount of methyl formate and methyl acetate) containing DMC, methyl alcohol and water and come from water phase rectifying tower 4 tower top material 15, product rectifying tower 3 tower top material 14 and methanol recovery tower still material 11 (mainly water) and a small amount of the second solvent n-hexane 10 (boiling point is 68.7 ° C, almost insoluble in water) enter the extractor 1 together, and an appropriate amount of the second solvent n-hexane is added in advance in the extractor 1 to carry out Vapor-liquid, liquid-liquid mass and heat transfer. The gas after this process is drawn out from the top of the extractor 1, and the liquid is drawn out from the bot...

Embodiment 4-6

[0039] The whole process flow is the same as that of Examples 1-3, except that the nonpolar solvents used in Examples 4-6 are cyclohexane, cyclopentane, and n-heptane, and their boiling points are respectively 80.7°C, 49.2°C, and 98.4°C. ℃, the common point is that they are insoluble in water.

[0040] The test conditions and results are shown in the attached tables listed in Fig. 8, Fig. 9 and Fig. 10.

[0041] By adopting the technological method of the patent invention, the azeotrope of methanol and DMC can be separated well, and the purity of the obtained DMC can reach more than 99.90%, and the total yield of DMC is more than 99%. The process has good operability and a wide operating range, and can obtain good separation effects in a wide range of conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com