Profile peeling device capable of feeding stably

A feeding device and feeding technology, applied in feeding devices, metal processing machinery parts, metal processing, etc., can solve problems such as inconsistent peeling thickness, force deviation, and affecting production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

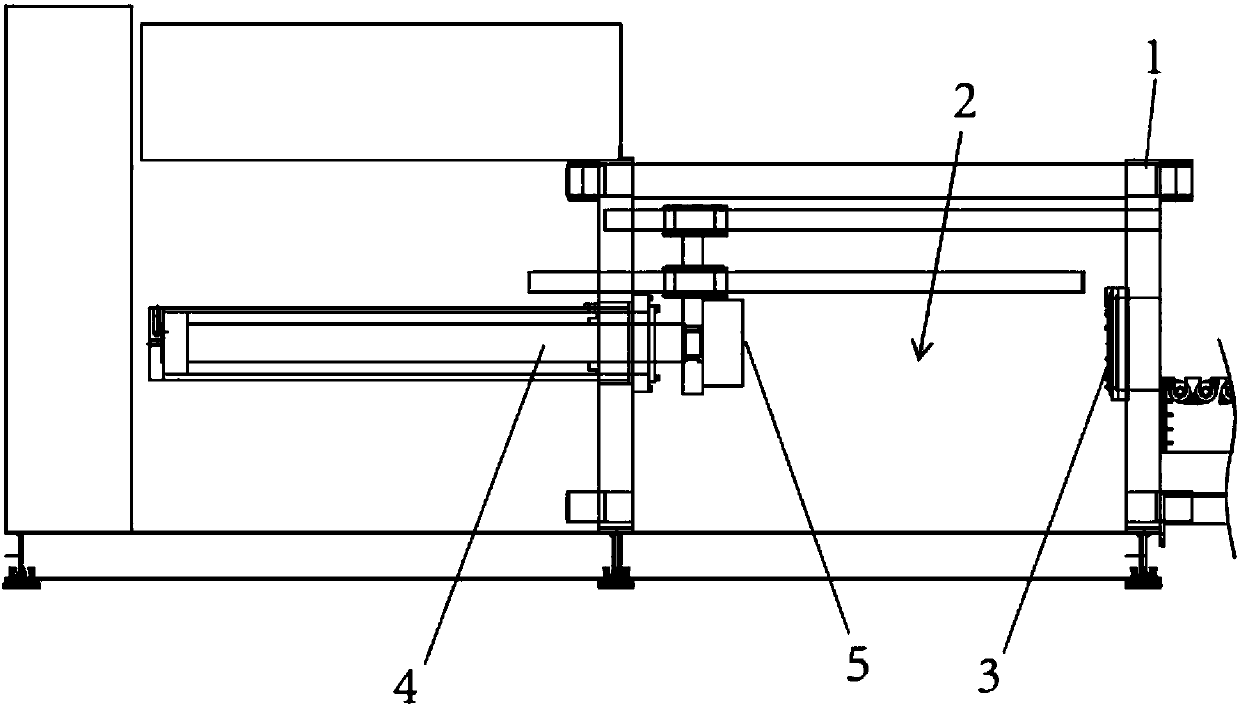

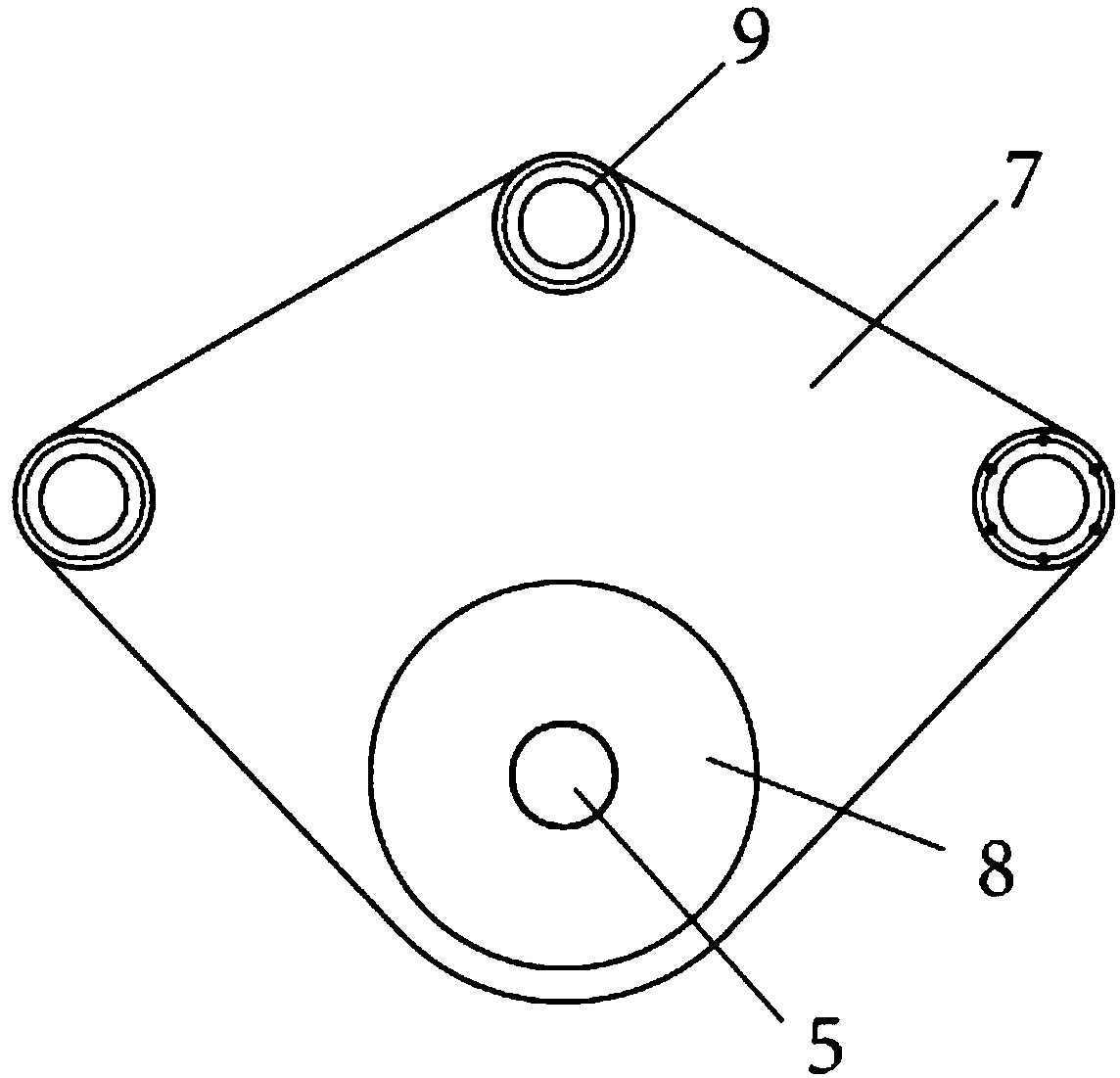

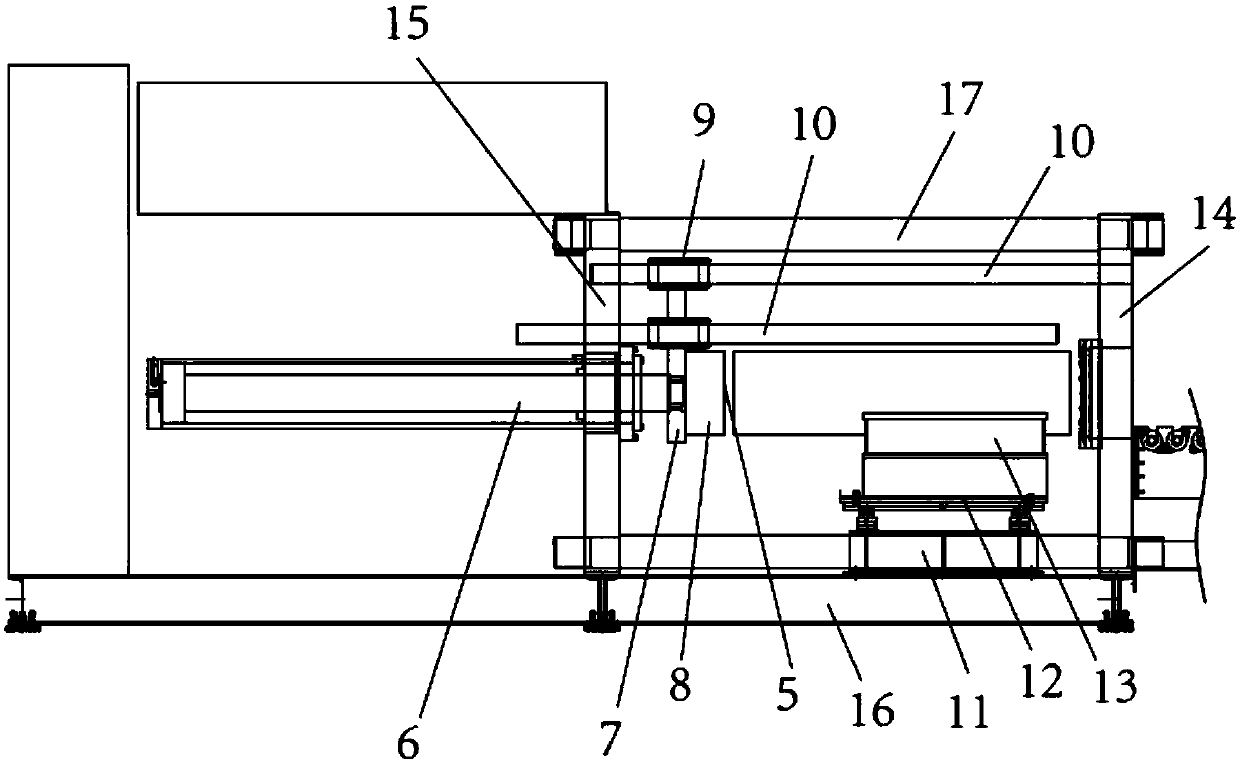

[0020] refer to figure 1 As shown, an embodiment of the profile peeling device of the present invention, comprising a frame 1, is provided with a peeling area 2 on the frame, and is provided with a peeling cutter 3 and an extruding part 4 in the peeling region, and the peeling cutter and the extrusion There is a feeding space between the pressing parts. After the profile enters the feeding space, the extrusion part pushes the profile to the peeling tool and cooperates with the peeling tool for peeling; the extrusion part is located on the end surface of the peeling tool. The positioning convex part 5, the positioning convex part is in contact with the end surface of the profile, and the positioning convex part can be pressed into the profile after the abutment, so that the profile end surface has a positioning concave part. Of course...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com