Periodic bowl-shaped structural template and preparation method thereof

A structural template and periodic technology, applied in the field of micro-nano structure preparation and application, can solve the problems of limiting the design ideas of micro-nano devices, the precision cannot reach the micro-nano level, and the manufacture of curved surface structures cannot be realized, and the preparation method is simple and practical , Uniform size and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

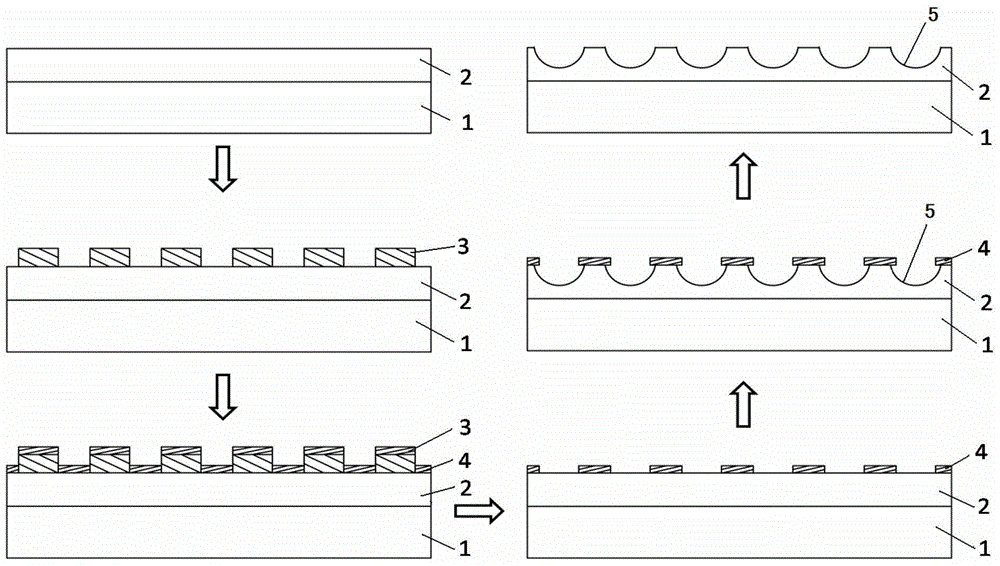

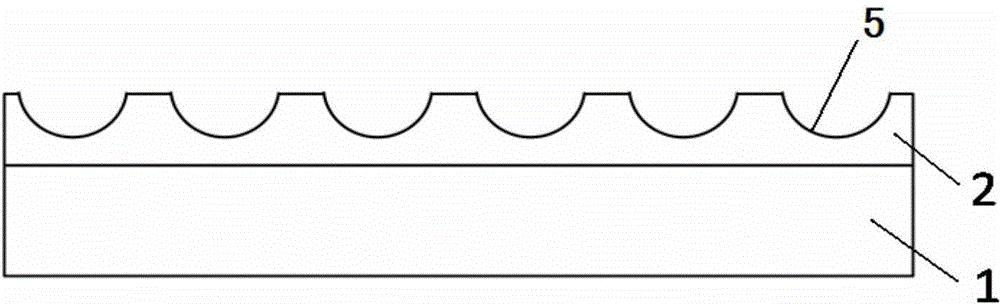

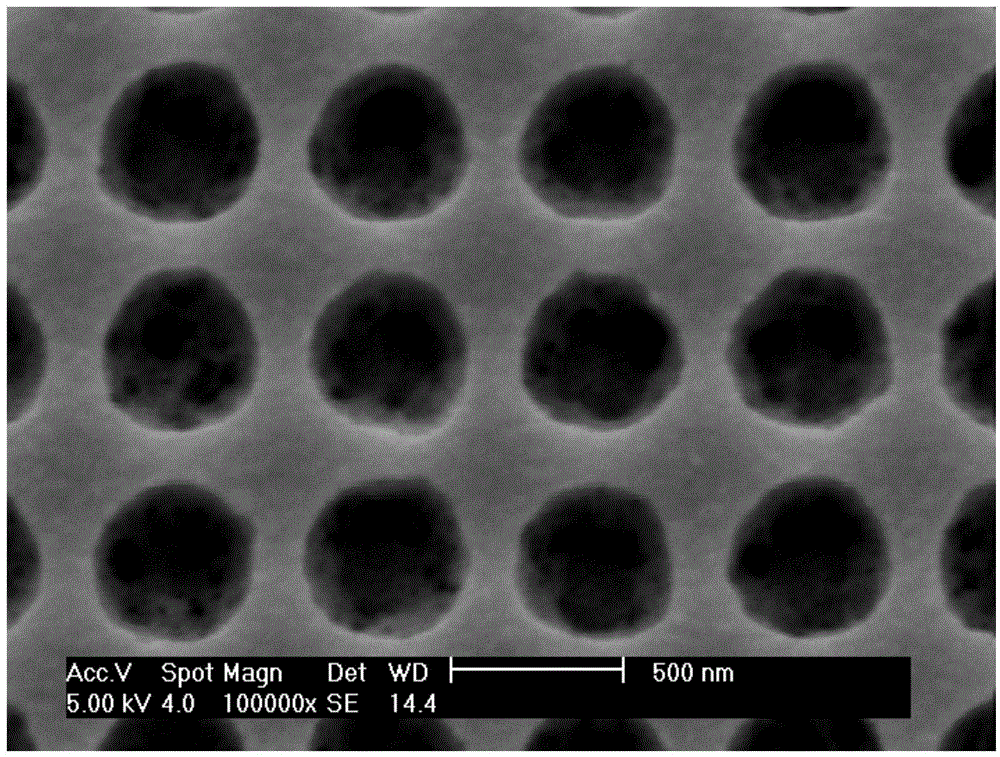

[0031] The invention belongs to the technical field of micro-nano processing, and specifically relates to a preparation method of a template with a periodic bowl-shaped structure, comprising: depositing a silicon dioxide 2 mask layer on a substrate 1, spin-coating a photoresist 3 thereon, and preparing Periodic micro-nano photoresist 3 dot matrix patterns, deposit a layer of metal film 4 on the photoresist 3 structure, after peeling off to obtain a pattern of 5 arrays of metal holes, and then use the structure of 5 arrays of metal holes as a mask, use a wet method Etching techniques form the silicon dioxide 2 bowl-shaped array structure, and finally remove the metal mask. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com