Method for preparing binder-free graphite product

A technology of graphite products and binderless, which is applied in the field of preparation of binderless graphite, can solve the problems of large discharge of asphalt volatiles, and cracked waste products of isostatic pressing products, so as to achieve smooth removal channels and reduce cracked waste products. , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

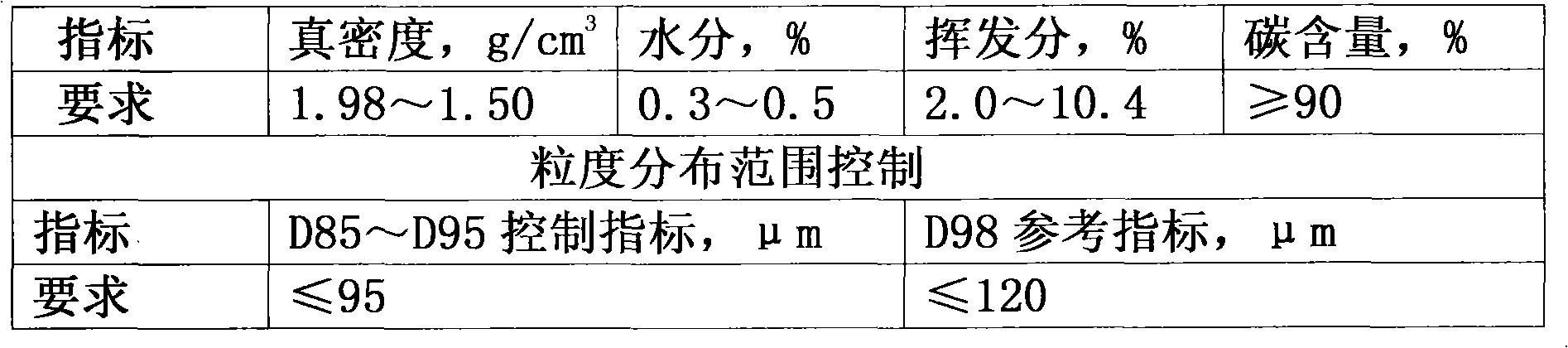

[0007] A method for preparing a binder-free graphite product of the present invention is composed of raw petroleum coke with a weight content of 10% to 30% and coal tar pitch mesophase pellet powder with a weight content of 70% to 90%. Dry and dehydrate raw petroleum coke, moisture ≤ 0.5%, drying temperature 130°C, drying time 24 hours; pre-oxidize coal tar pitch mesophase pellets at 120°C, use resistance furnace to freely heat up to 120°C, keep warm 2 hours, naturally cooled to room temperature for later use. Use a crusher to crush the dried and dehydrated raw petroleum coke. The crushed raw petroleum coke is ground into raw petroleum coke powder through a ball mill and an airflow mill in turn. The particle size of the ball mill is controlled at D85~D95≤150μm. The particle size of the machine mill powder is controlled at D85~D95≤60μm, and the raw petroleum coke powder with a weight of 10%~30% and the 70%~90% coal tar pitch mesophase ball powder with a particle size of D85~D95...

Embodiment 1

[0015] Embodiment 1: raw petroleum coke 300kg, coal tar pitch mesophase pellet powder 700kg;

Embodiment 2

[0016] Embodiment 2: raw petroleum coke 200kg, coal tar pitch mesophase pellet powder 800kg;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com