Solid biomass gasification system and process thereof

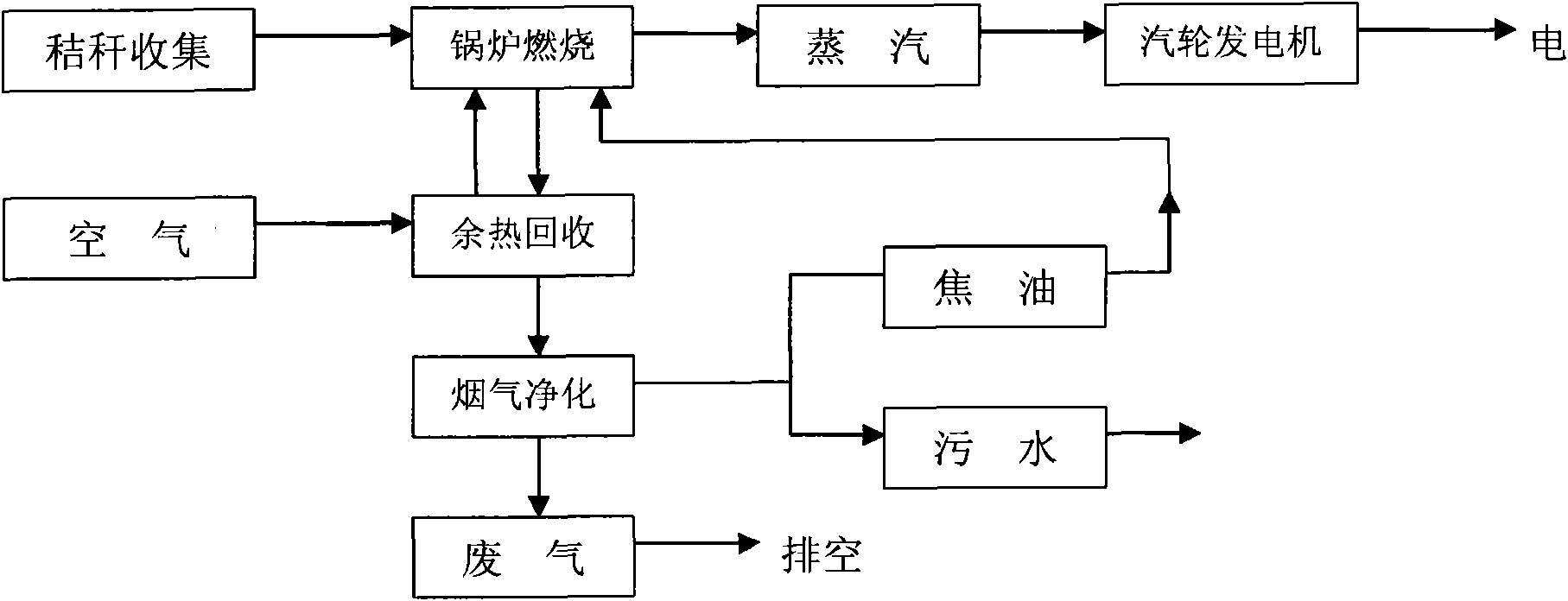

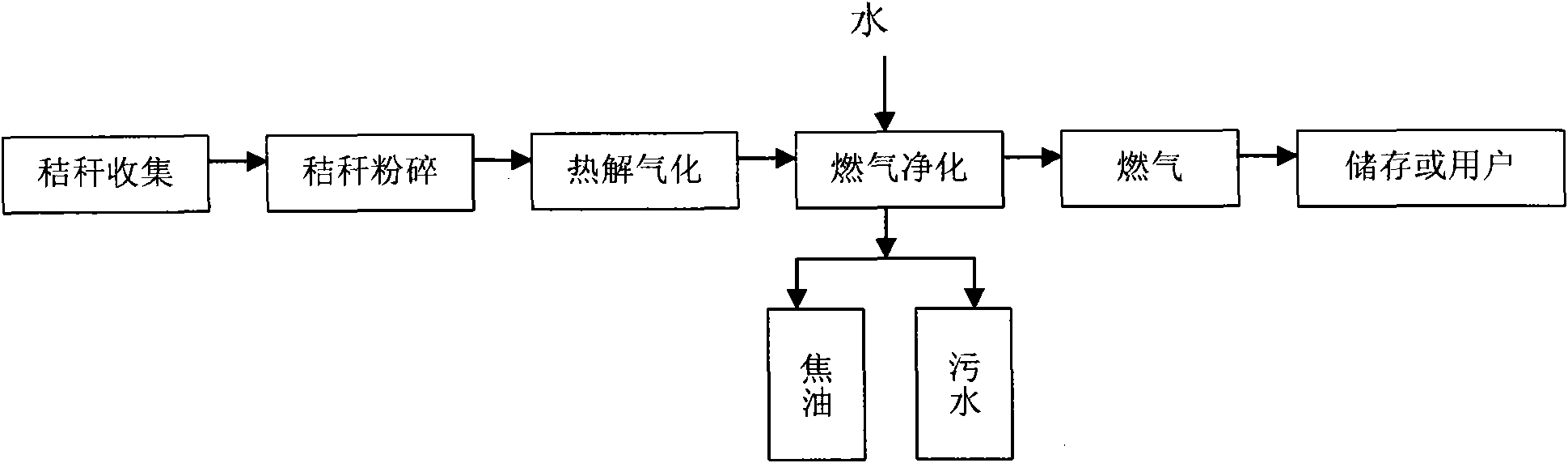

A solid biomass and process technology, which is applied in the petroleum industry and the manufacture of combustible gases, etc., can solve the problems of low gasification efficiency, great harm, and secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

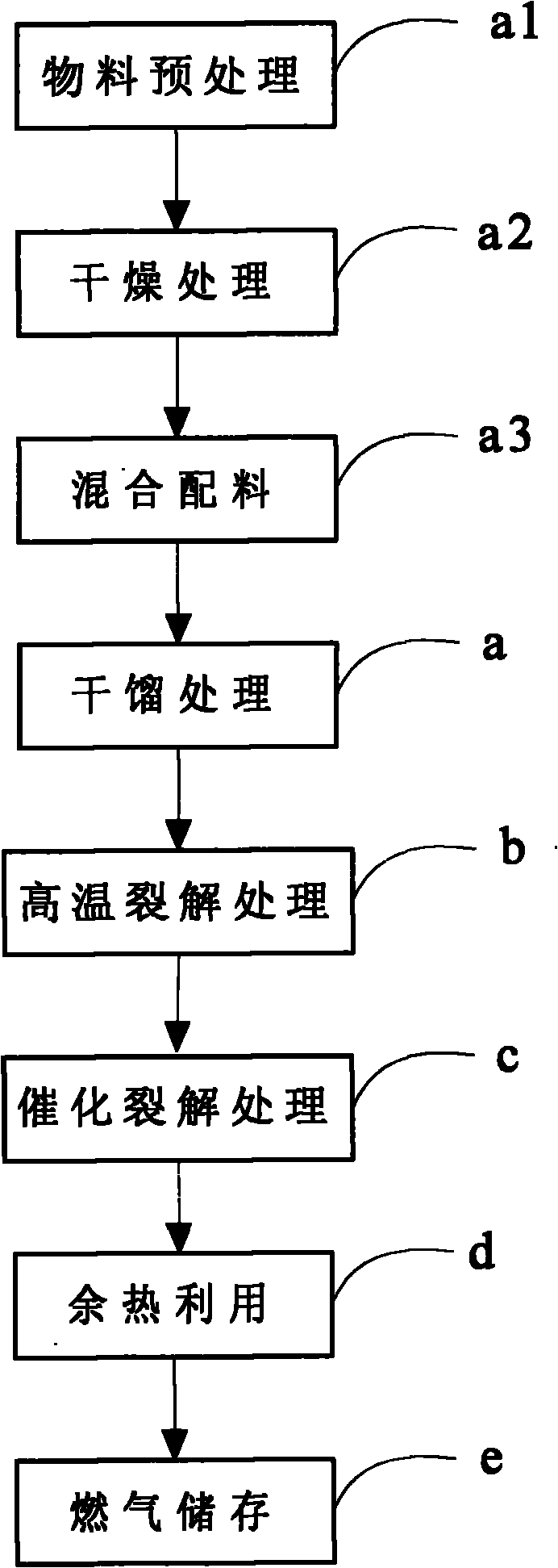

[0033] The invention provides a solid biomass gasification and cracking system and its process, which can reduce the pollution produced by the traditional gasification process and improve the gasification efficiency and fuel gas quality.

[0034] The main idea of the solid biomass gasification and cracking process provided by the present invention is to combine retort gasification with high-temperature pyrolysis gasification and catalytic cracking technology, so that the retort gasification products are completely gasified and cracked or decomposed, and the biocoke is completely Oxidation and reduction, cracking tar particles in retort gas into combustible gases, decomposing heavy metal salts into environmentally friendly and stable metal oxides, so as to achieve the purpose of the present invention without tar, pollution and high gasification rate.

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com