Firewood coal furnace

A technology for a charcoal furnace and a furnace body, which is applied in the field of fuel charcoal furnaces, can solve the problems of low combustion temperature, environmental pollution by thick smoke and dust, and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

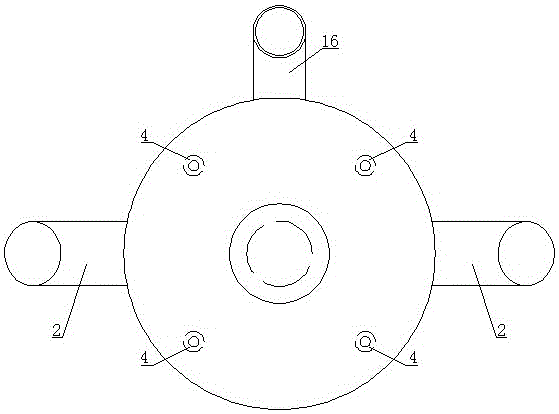

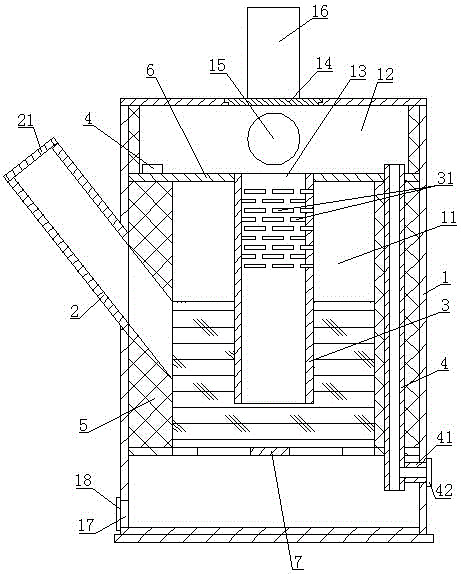

[0018] Such as figure 1 As shown, the charcoal burning furnace includes a cylindrical furnace body 1, and a partition plate 6 arranged horizontally is arranged in the furnace body 1 close to its upper part, and the partition plate 6 divides the inner chamber of the furnace body 1 into an upper combustion chamber 12 and The lower combustion chamber 11. Body of furnace 1 is provided with refractory material 5 on the inner surface ring corresponding to the combustion chamber, and refractory material 5 encloses combustion chamber 11. Fire grate 7 is installed at the bottom of combustion chamber 11 in body of furnace 1 and ash box is arranged below fire grate 7. The furnace body 1 is provided with a soot removal port 17 and a soot removal door 18 that can close the ash removal port 17 corresponding to the ash box.

[0019] The middle part of the dividing plate 6 is provided with a second furnace mouth 13 which communicates the combustion chamber 12 with the combustion chamber 11. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com