Method for computing degree of direct reduction and gas utilization rate of blast furnace under condition of high-reactivity coke

A high-reactivity coke, calculation method technology, applied in the direction of blast furnace, calculation, blast furnace details, etc., can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

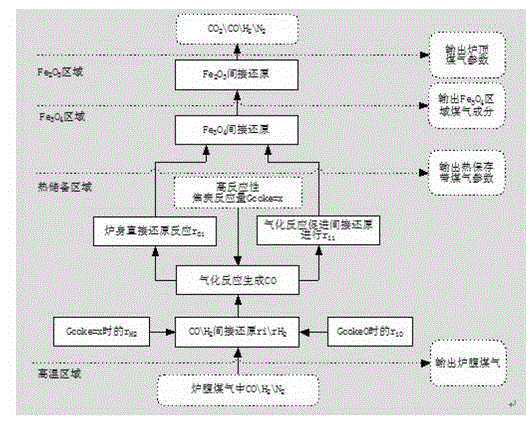

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Based on the production data of a large domestic steel plant such as raw materials, fuels, and operating processes, the calculation of the changes in the ratio of highly reactive coke added from 0% to 12%, the direct reduction degree, indirect reduction degree, and gas utilization rate of the blast furnace , and the calculation results are shown in Table 1.

[0043] Table 1 Analytical calculation results of adding high reactivity coke (HRC)

[0044]

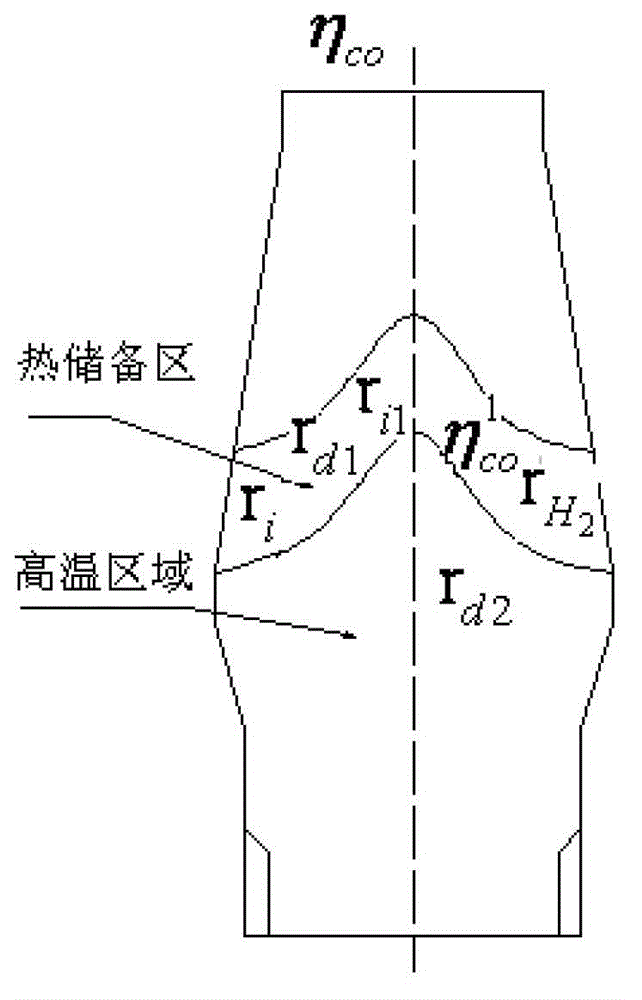

[0045] It can be seen from Table 1 that when the reaction amount of high-reactivity coke is increased from 0 to 12%, the indirect reduction degree of blast furnace smelting increases from 0.440 to 0.453, and the direct reduction degree decreases from 0.400 to 0.348. degree from 0.400 to 0.255, the utilization rate of gas in the thermal reserve area increased from 25.18% to 30.12%, and the utilization rate of blast furnace gas increased from 52.15% to 59.33%, indicating that adding a certain proportion of highly reactive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com