Method for preparing coke by using direct coal-liquefied residue

A technology for direct coal liquefaction and coal liquefaction, which is used in the processing of tar pitch/petroleum pitch/natural pitch, tar pitch/petroleum pitch/natural pitch by chemical methods, and tar pitch/petroleum pitch/natural pitch by selective extraction, etc. It can solve the problems of high price, high cost and complex process, and achieve the effect of strong development practicability, reasonable utilization and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

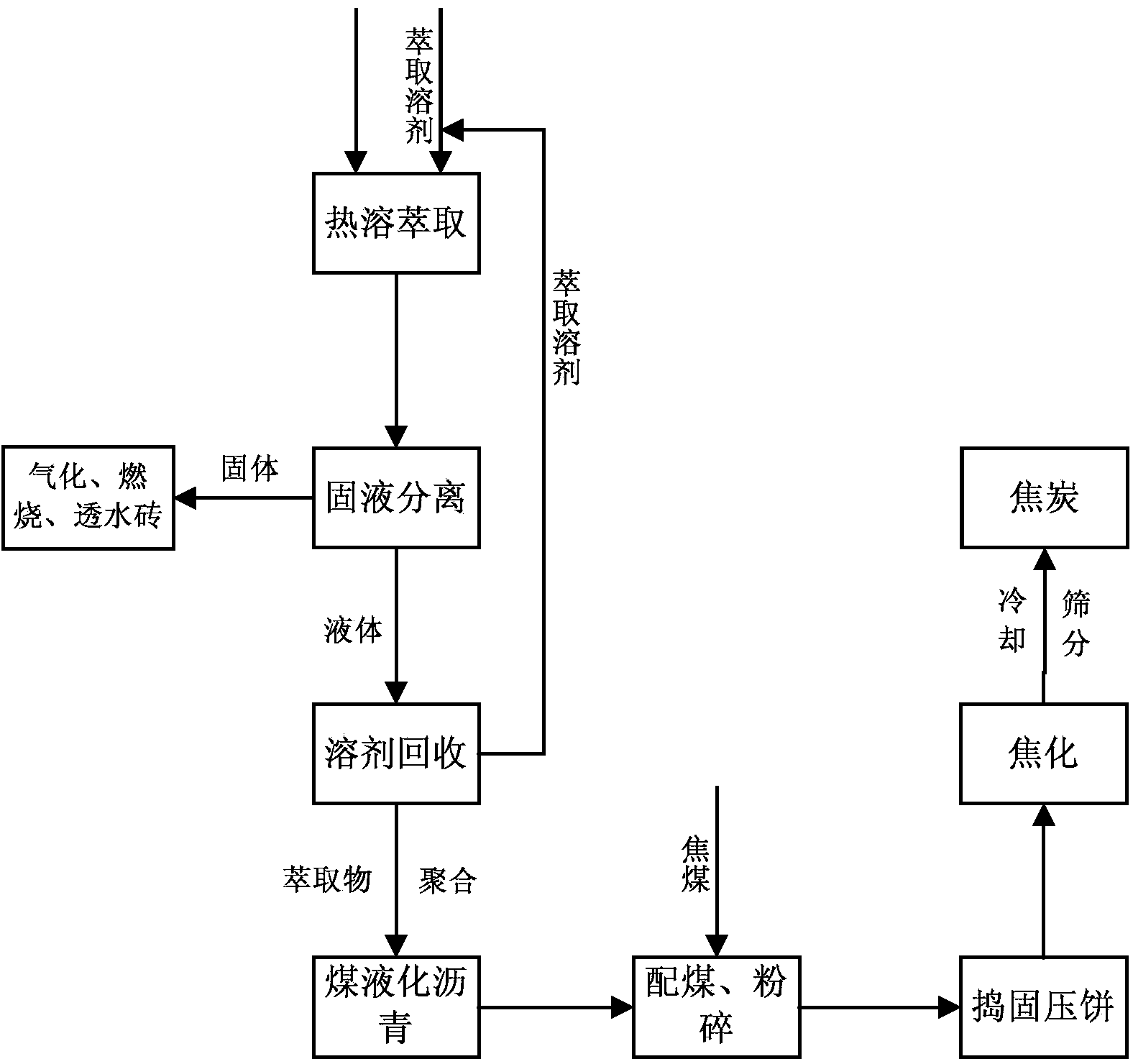

[0027] According to a typical embodiment of the present invention, the step of preparing the coal liquefaction modified asphalt includes: S11, mixing the coal direct liquefaction residue with the extraction solvent, stirring, and hot-melting extraction to obtain a hot-melting extraction mixture; S12, extracting the hot-melt The mixture is subjected to solid-liquid separation to obtain an extract and a raffinate; S13, solvent recovery is performed on the extract to obtain an extract; and S14, the extract is polymerized and modified to obtain a coal liquefaction modified asphalt.

[0028] In order to optimize the process of preparing the hot melt extraction mixture, preferably, step S11 includes: mixing the coal direct liquefaction residue with the extraction solvent in a mass ratio of 1:1-10 to obtain a mixed liquid; and S12, passing into the mixed liquid N 2 , And at 0.15~0.3MPa at 10℃~30℃ / h, the mixture is heated to 150℃~200℃, stirred at constant temperature, hot melt extraction,...

Embodiment 1

[0037] 1) Add 300kg of coal direct liquefaction residue and 750kg of naphthalene oil (distillation range of 160~260℃) into the stirred tank, stir at a rate of 60r / min to obtain a mixed liquid, and fill the stirred tank with N 2 When the pressure in the stirring tank reaches 0.2 MPa, the mixture is heated to 150° C. at a rate of 10° C. per hour, then stirred at a constant temperature of 300 r / min, and hot-melt extraction is performed for 30 minutes to obtain a hot-melt extraction mixture.

[0038] 2) The hot-melt extraction mixture is subjected to solid-liquid separation by hot-pressure filtration. The filtration temperature is 250°C, the filtration pressure is 2.0 MPa, and the pore size of the filter element is 50 μm. After primary filtration, 867 kg of extract and 180 kg of raffinate were collected.

[0039] 3) The extract is sent to the vacuum distillation tower for solvent recovery. The extraction solvent at 120-210°C is recovered at the top of the tower for recycling. The extra...

Embodiment 2

[0044] 1) Add 300kg coal direct liquefaction residue and 3000kg coal liquefaction medium oil (distillation range 150~310℃) into the stirred tank, stir at a rate of 75r / min, and charge the stirred tank with N 2 When the pressure in the stirring tank reaches 0.3 MPa, the temperature is increased to 170° C. at a rate of 30° C. per hour, and the mixture is stirred at a constant temperature for 45 minutes with hot melt extraction and at a rate of 50 r / min for constant temperature stirring to obtain a hot melt extraction mixture.

[0045] 2) The hot-melt extraction mixture is subjected to solid-liquid separation by hot-pressure filtration. The filtration temperature is 120°C, the filtration pressure is 0.4MPa, and the pore size of the filter element of the filter is 40μm. After filtration, the extract and raffinate were collected.

[0046] 3) The extract is sent to the vacuum distillation tower for solvent recovery, and the extraction solvent at 120-210°C is recycled at the top of the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com