Modified asphalt, method for continuous preparation of modified asphalt by using coal direct liquefaction residue under normal pressure and its application

A technology of direct coal liquefaction and modified asphalt, which is applied to the processing of tar pitch/petroleum pitch/natural pitch, processing tar pitch/petroleum pitch/natural pitch by chemical methods, and processing tar pitch/petroleum pitch/natural pitch by selective extraction and other directions, it can solve the problems of increasing the complexity of the process and the inability to carry out continuous production, and achieve the effect of good market application prospects, strong development applicability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

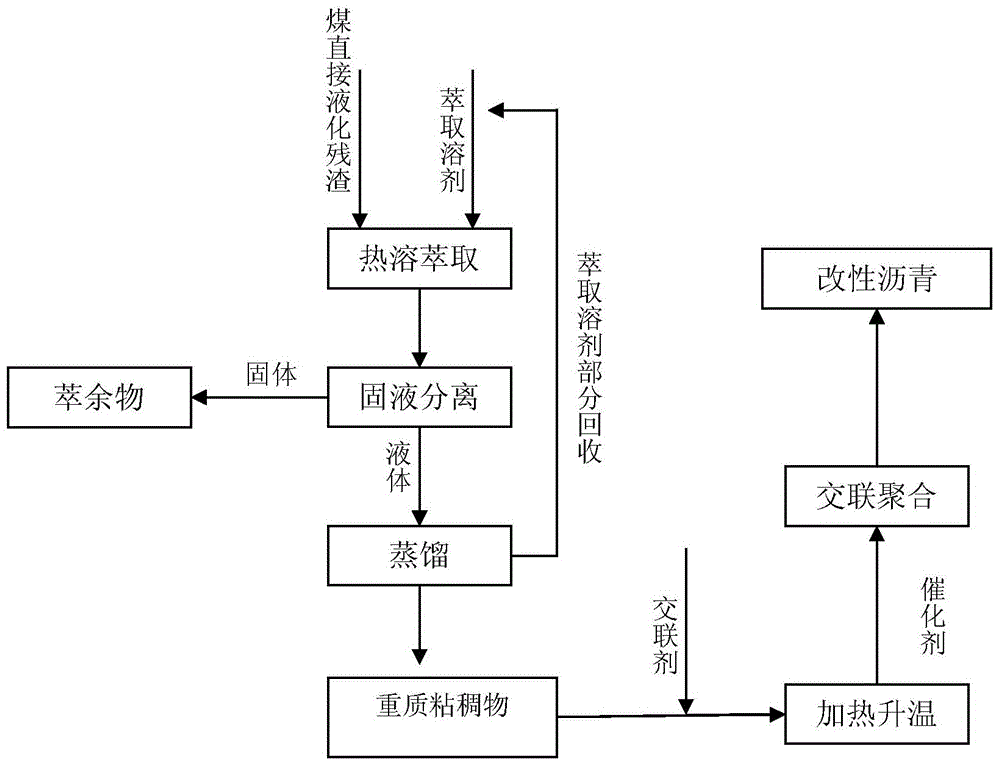

Method used

Image

Examples

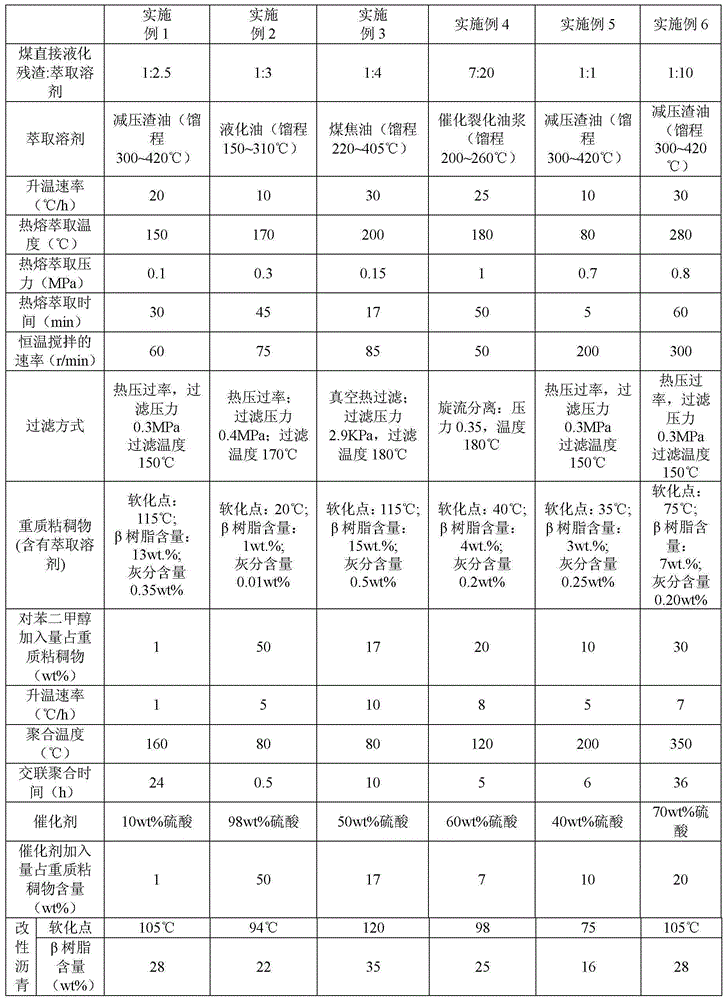

Embodiment 1

[0044] 1) Add 300Kg coal direct liquefaction residue and extraction solvent vacuum residue (distillation range: 300-420°C) into the stirred tank (the weight ratio of coal direct liquefaction residue to vacuum residue is 1:2.5), at 60r / min speed stirring to obtain a mixture. Fill the stirred tank with N 2 When the pressure in the stirred tank was raised to 0.1 MPa, the temperature of the mixture was raised to 150°C at 20°C / hour, then stirred at a constant temperature of 300r / min, and subjected to hot-solution extraction for 30min to obtain an extraction mixture.

[0045] 2) Solid-liquid separation of the extraction mixture is carried out by means of hot-press filtration. The filtration temperature is 150° C., the filtration pressure is 0.3 MPa, and the pore size of the filter core is 30 μm. After filtration, the extract and raffinate were collected.

[0046] 3) Send the extract to a vacuum distillation tower for vacuum distillation to recover the solvent. The temperature at...

PUM

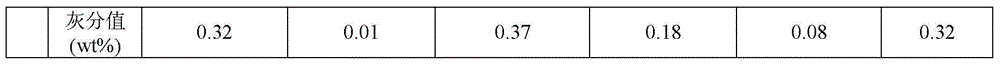

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com