Method for recycling valuable metals from waste lithium ion batteries and/or other materials

A lithium-ion battery and valuable metal technology, applied in the field of resources and the environment, can solve problems such as complex process, depletion, and inability to directly discard slag, and achieve the effect of simplified process and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

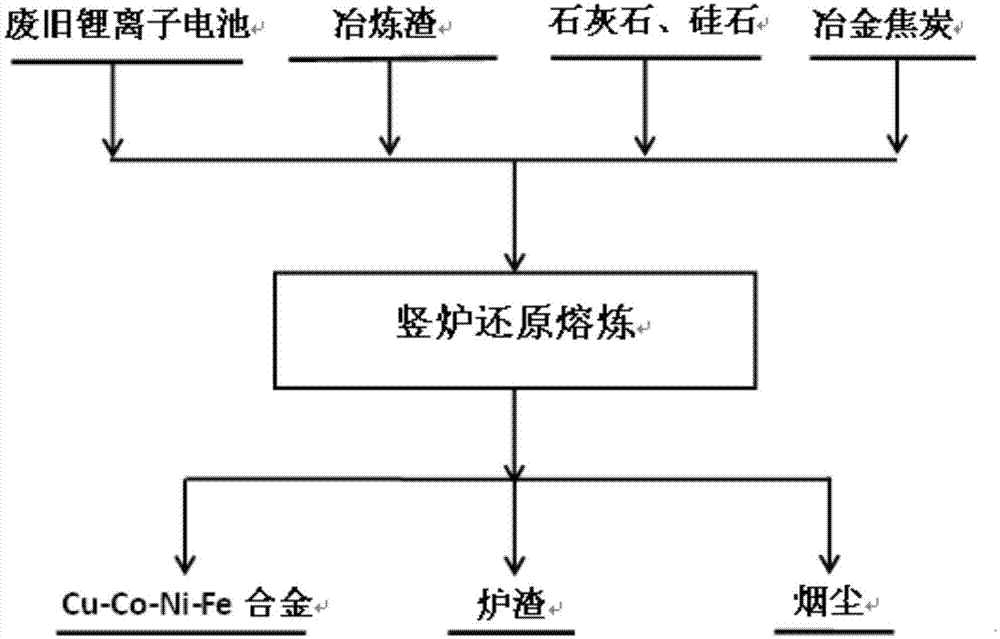

Method used

Image

Examples

Embodiment 1

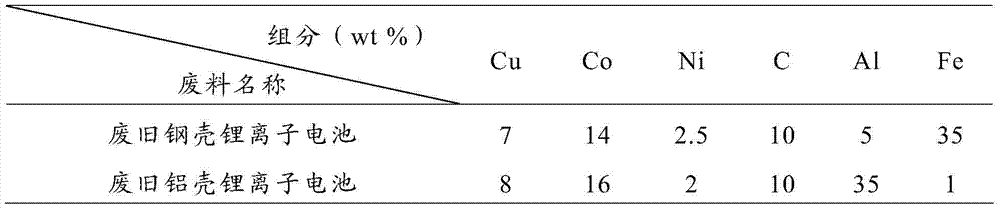

[0052] The waste and old steel shell lithium ion battery, limestone, silica and metallurgical coke are mixed to obtain a mixed material, wherein, the limestone of 23.7wt%, the silica of 17.3wt%, and the metallurgical coke of 12wt% are mixed; in the mixed material, CaO / SiO 2 =1.3.

[0053] Put the mixed material into the shaft furnace at a speed of 300kg / h for reduction smelting, the melting temperature is 1450°C, the melting time is 60min, and the flue gas temperature at the top of the furnace is 450°C. After the slag is completely separated from the alloy melt, the superalloy and the slag are released from the alloy port and the slag outlet respectively to obtain Cu-Co-Ni alloy and slag.

[0054] Among the produced alloys, the recoveries of Cu, Co and Ni were 96.9%, 98.1% and 96.8%, respectively; Cu, Co and Ni contained in the slag were 0.35wt%, 0.31wt% and 0.05wt%, respectively. The results show that the present invention reduces the content of valuable metals in slag whi...

Embodiment 2

[0056] The waste steel shell lithium ion battery, copper slag (Cu1wt%, TFe42wt%), nickel slag (Cu0.2wt%, Ni0.35wt%, TFe44wt%), cobalt slag (Cu3wt%, Co3.5wt%, TFe42wt%), Limestone and metallurgical coke are mixed, obtain mixed material, wherein, by the copper slag of 10.4wt%, the cobalt slag of 6.9wt%, the nickel slag of 17.3wt%, the limestone of 21.7wt%, the metallurgical coke of 9wt% are mixed; In mixed materials, CaO / SiO 2 =1.3.

[0057] The mixed material was put into the shaft furnace at a rate of 300kg / h for reduction smelting, the smelting temperature was 1450°C, the smelting time was 60min, and the flue gas temperature at the top of the furnace was 450°C. After the slag is completely separated from the alloy melt, the superalloy and the slag are released from the alloy port and the slag outlet respectively to obtain Cu-Co-Ni alloy and slag.

[0058] Among the produced alloys, the recoveries of Cu, Co and Ni were 97.1%, 96.9% and 96.0%, respectively; Cu, Co and Ni cont...

Embodiment 3

[0060] Mix waste and old aluminum case lithium-ion batteries, copper slag (Cu1wt%, TFe42wt%) and limestone to obtain a mixed material, wherein, mix 49.8wt% copper slag and 25.4wt% limestone; in the mixed material, CaO / SiO 2 =1.3.

[0061]Put the mixed material into the shaft furnace at a speed of 300kg / h for reduction smelting, the melting temperature is 1450°C, the melting time is 60min, and the flue gas temperature at the top of the furnace is 450°C. After the slag is completely separated from the alloy melt, the superalloy and the slag are released from the alloy port and the slag outlet respectively to obtain Cu-Co-Ni alloy and slag.

[0062] Among the produced alloys, the recoveries of Cu, Co and Ni were 95.8%, 97.0% and 95.2%, respectively; Cu, Co and Ni contained in the slag were 0.45wt%, 0.41wt% and 0.10wt%, respectively. The results show that the present invention reduces the content of valuable metals in slag while realizing efficient recovery of valuable metals. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com