Swinging automatically spraying and drying machine

A rotary and dryer technology, applied in dryers, drying, hearth furnaces, etc., can solve the problems of wasting materials, low work efficiency, poor coating uniformity, etc., and achieve accurate spraying and drying. Quick, paint-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

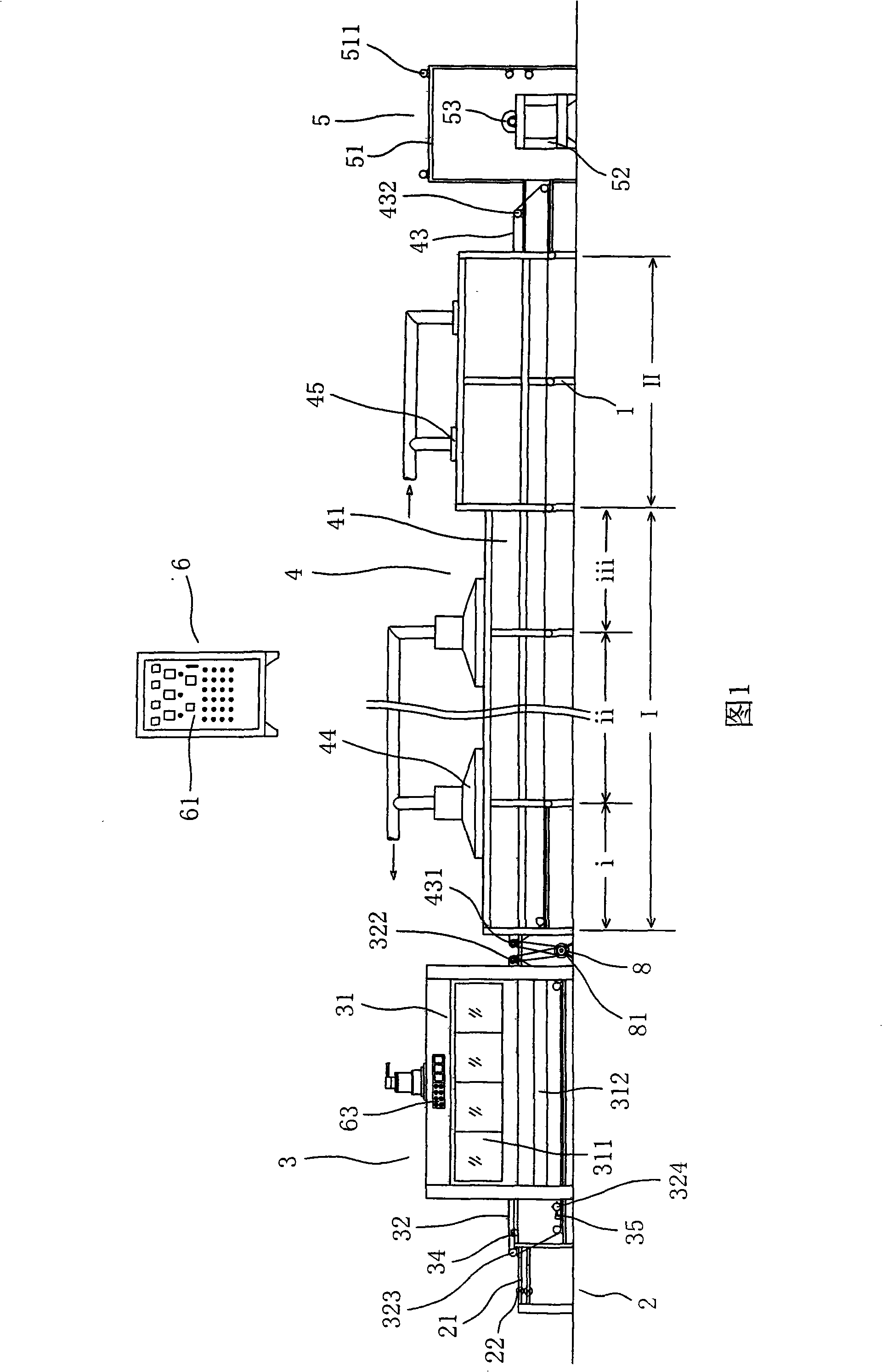

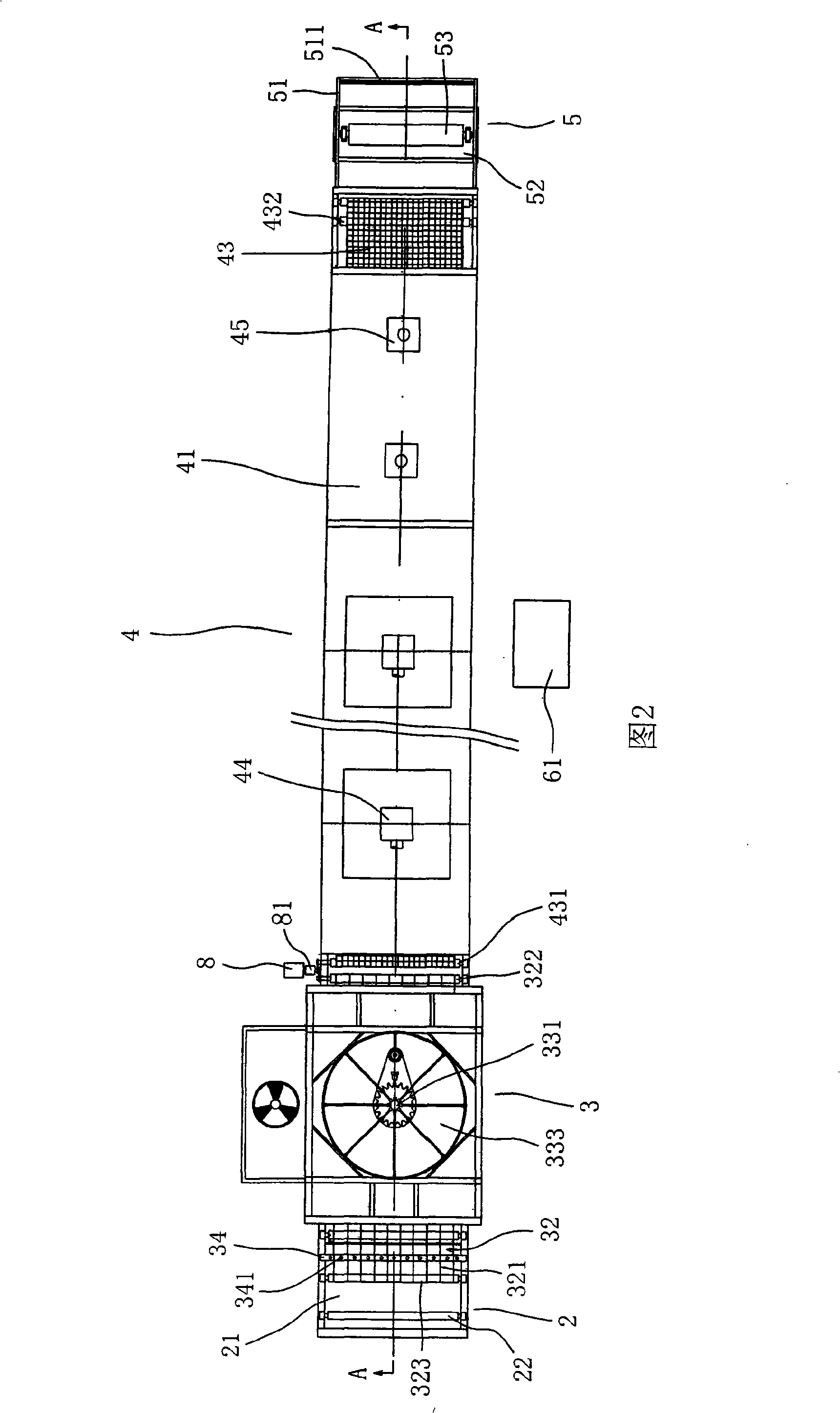

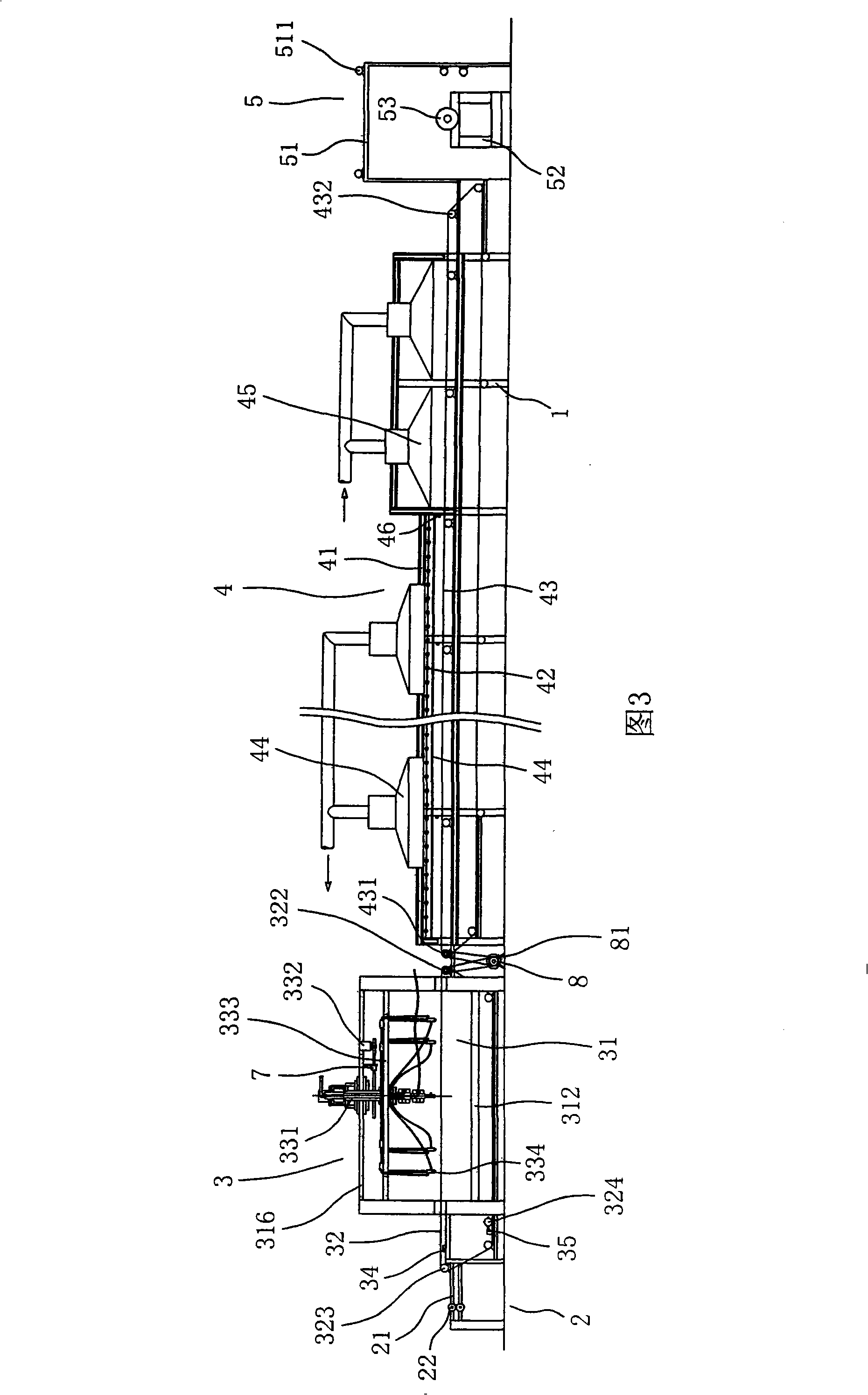

[0035] Refer to Figures 1 to 3. The rotary automatic spraying dryer includes a frame 1, a discharge mechanism 2, a spray booth 3, a drying room 4, a material receiving mechanism 5, and a microcomputer control system 6 installed on the frame 1 in sequence.

[0036] Refer to Figures 1 to 3. Unwinding mechanism 2: includes an operating platform 21, which is equipped with a feed roller 22 connected to a drive motor (not shown in the figure), and the cloth to be sprayed is placed on the operating platform 21 and passed by the feed roller 12 The front conveying cloth is sprayed and dried through the spraying room 3 and the drying room 4 in turn.

[0037] Refer to Figures 1 to 5. Spray booth 3: including the spray box 31 fixed on the frame 1 and adjacent to the discharge mechanism 1, the side wall of the spray box 31 is equipped with an openable glass observation window 311 that is convenient for the operator to monitor the working condition of the spray gun in real time, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com