Chemical vapor deposition method

A technology of chemical vapor deposition and equipment, which is applied in the direction of gaseous chemical plating, electrical components, coatings, etc., and can solve problems such as uneven plasma and thin film deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

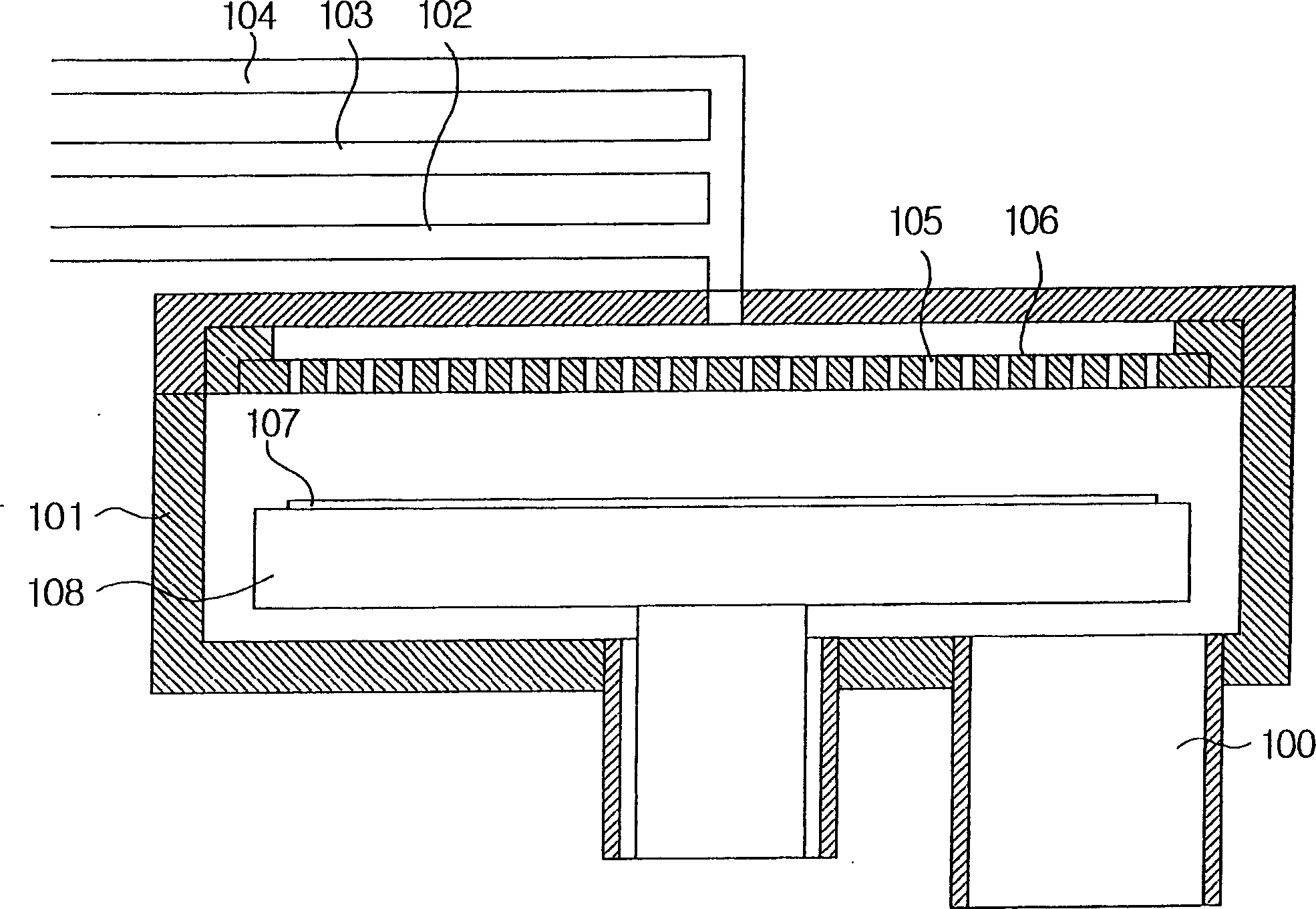

[0034] Figure 2A is a schematic diagram showing structural elements of a radical assisted chemical vapor deposition apparatus capable of sequentially supplying process gases according to the first embodiment of the present invention.

[0035] As can be seen from this figure, the chemical vapor deposition equipment involved in the present invention has such a structure that it is formed by sequentially supplying process gas including the steps of injecting and cleaning source gas and injecting and cleaning reaction gas. Films in which reactive gases are injected in such a state that plasma is generated in the shower head after they are injected.

[0036] Such as Figure 2A As shown in , in the chemical vapor deposition equipment involved in the present invention, the top plate 212 is installed on the top of the chamber 201 and constitutes a part of the chamber 201, the RF power supply connection part 209 that can be connected with the external RF power supply 210 Mounted on ...

no. 2 example

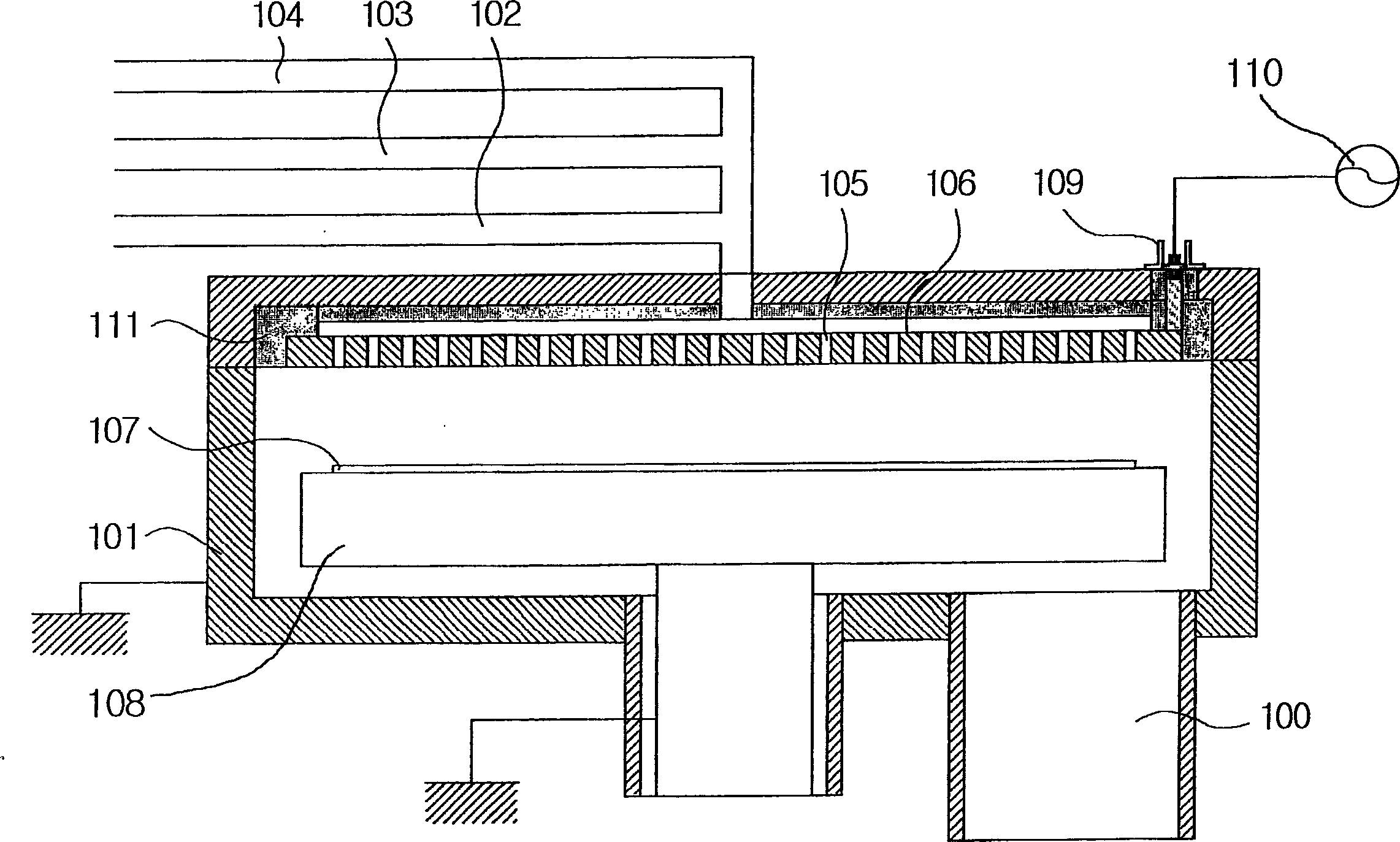

[0051] Figure 3A is a structural element representing a radical assisted chemical vapor deposition apparatus capable of sequentially supplying process gases and generating plasma in the upper portion of a shower head partitioned in a predetermined manner according to the second embodiment of the present invention A schematic diagram of .

[0052] As can be seen from this figure, the chemical vapor deposition equipment involved in the present invention has such a structure that it is formed by sequentially supplying process gas including the steps of injecting and cleaning source gas and injecting and cleaning reaction gas. thin film; by separating the shower head into two parts to separate the first part into which the source gas is introduced and injected from the second part into which the reaction gas is introduced and injected, the mixing between the source gas and the reaction gas can be completely prevented; After the reaction gas, radicals of the reaction gas may be e...

no. 3 example

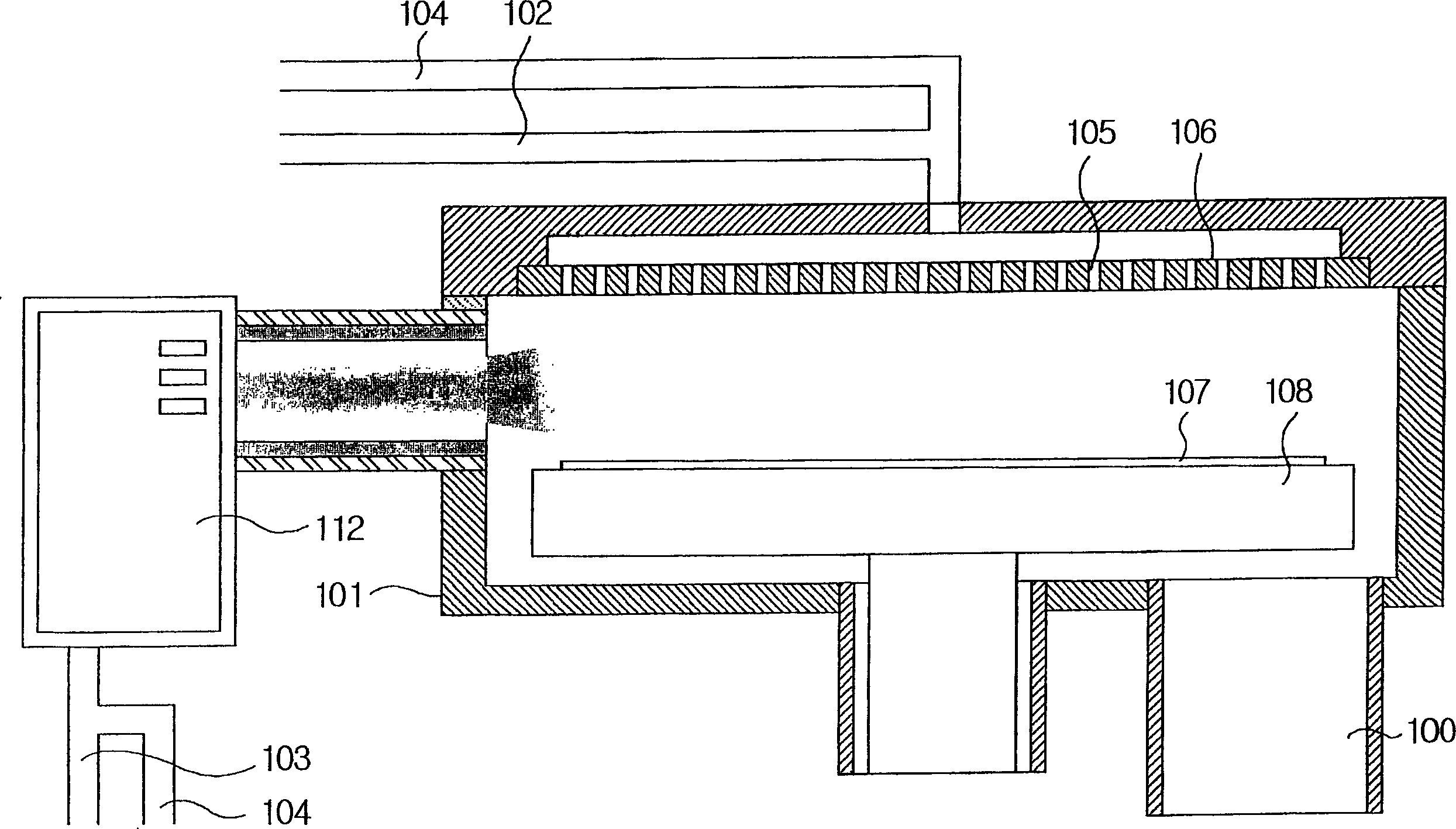

[0066] Figure 4 is a schematic diagram showing structural elements of a chemical vapor deposition apparatus capable of sequentially supplying process gases and using an external plasma generating apparatus according to a third embodiment of the present invention.

[0067] As shown in the figure, the chemical vapor deposition equipment involved in the present invention includes a chamber 401 with an outlet 400 in the lower part, a nozzle 406 in which a plurality of injection holes 405 for injecting process gas are formed, and a support for supporting A wafer or substrate 407 (hereinafter referred to as “substrate”) and simultaneously a heater 408 serving as a heat source enables thin film deposition on the substrate 407 by process gas injected through the shower head 406 .

[0068] A top plate 409 is mounted on top of the chamber 401 and forms part of the chamber 401 . External plasma generating devices 410 are connected to the chamber 401 and communicate with each other outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com