Method for drilling holes on soft coal seam to measure coal seam gas pressure

A technology of coal seam gas pressure and soft coal seam, applied in surveying, earthwork drilling, wellbore/well components, etc., can solve the problem that the mucus sealer is not placed in place, the pressure stabilization time is long, and the drilling is difficult to form a regular circle and other problems, to achieve the effect of reducing the amount of roadway engineering, high measurement accuracy, and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

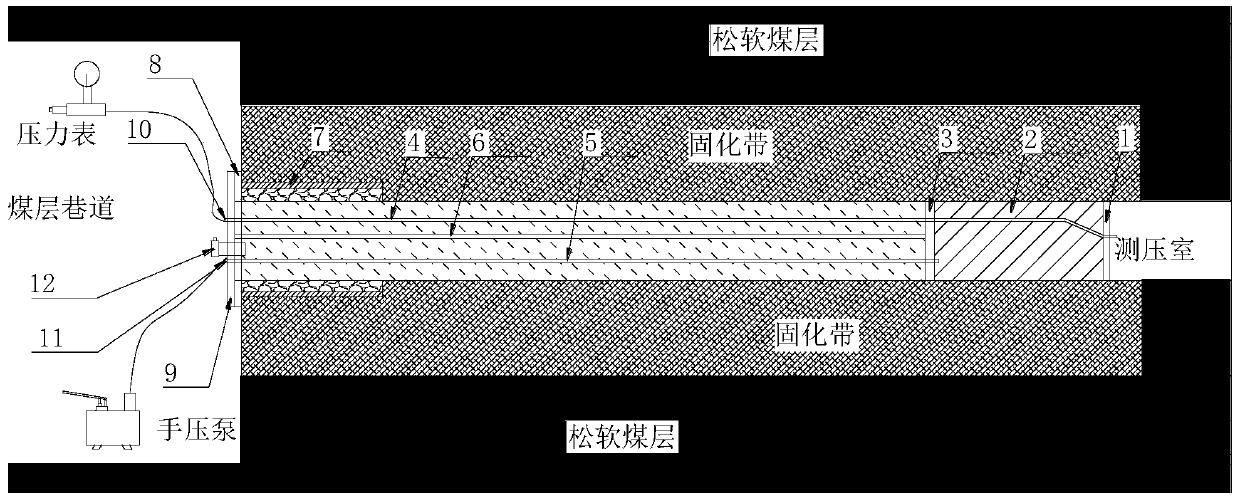

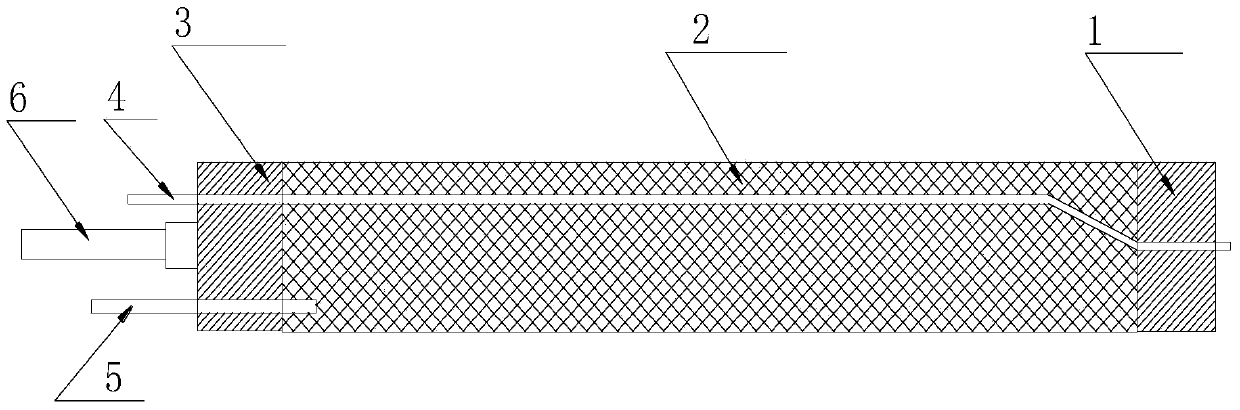

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

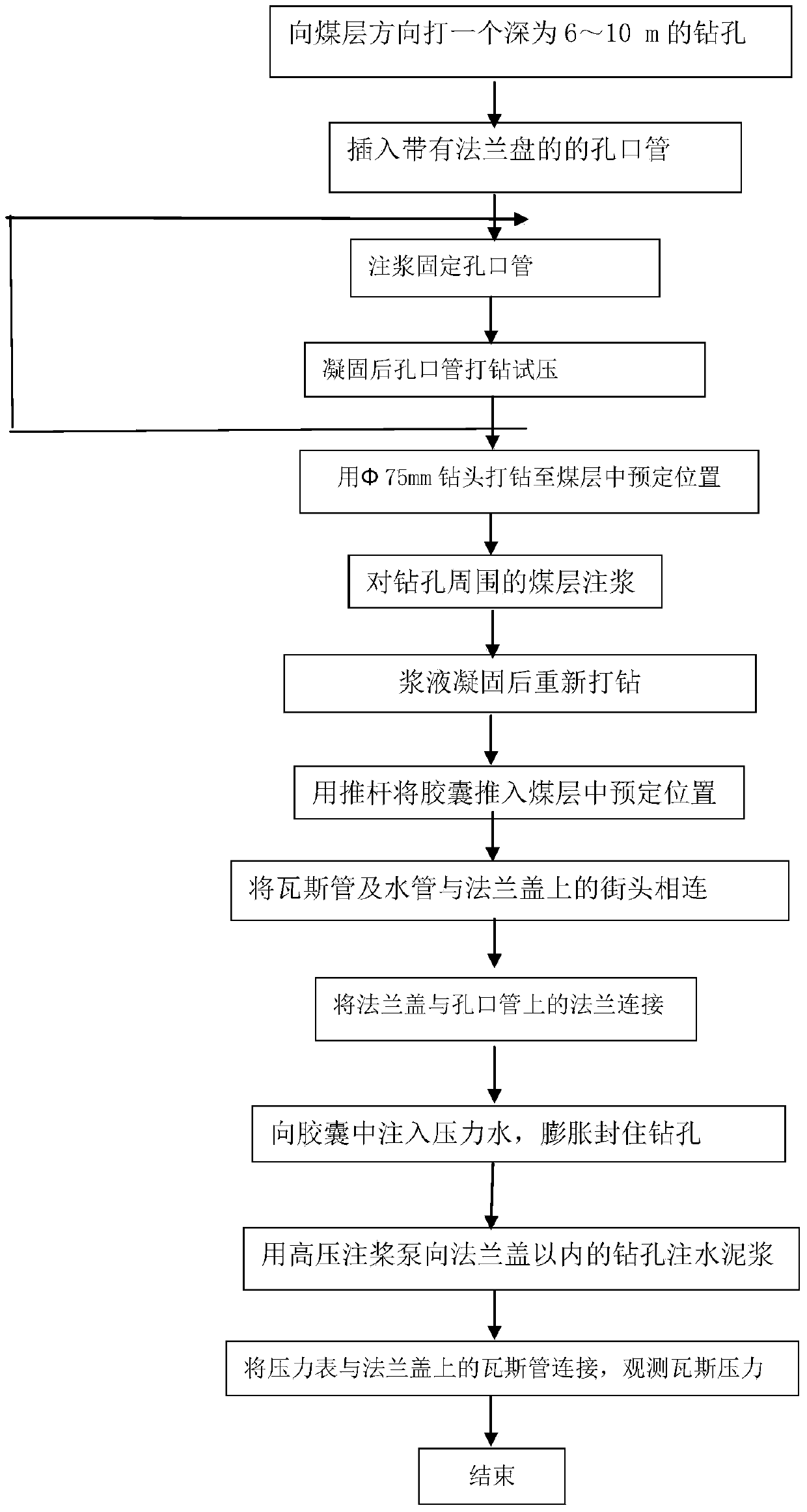

[0023] figure 1 As shown, the method for measuring coal seam gas pressure by drilling in soft coal seams of the present invention first carries out chemical grouting solidification to the coal body around the coal seam boreholes, then re-drills holes in the solidified coal seam, and places the capsule hole sealing device Deep in the coal seam, water injection expands to seal the borehole, and the hole inside the capsule hole sealing device forms a pressure measuring chamber, which is used to communicate with the pressure gas in the coal seam. The capsule hole sealing device forms a closed space with the external orifice pipe and flange cover, which is used to inject high-pressure cement slurry; the solidified cement slurry and capsule are used to seal and seal the drill hole tightly to ensure accurate gas pressure measurement. The concrete steps of the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com