No-seam steel felly making process

A manufacturing process and welding-free technology, which is applied in the field of manufacturing steel automobile wheels, can solve the problem of high production cost, and achieve the effects of low production cost, fuel consumption saving and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

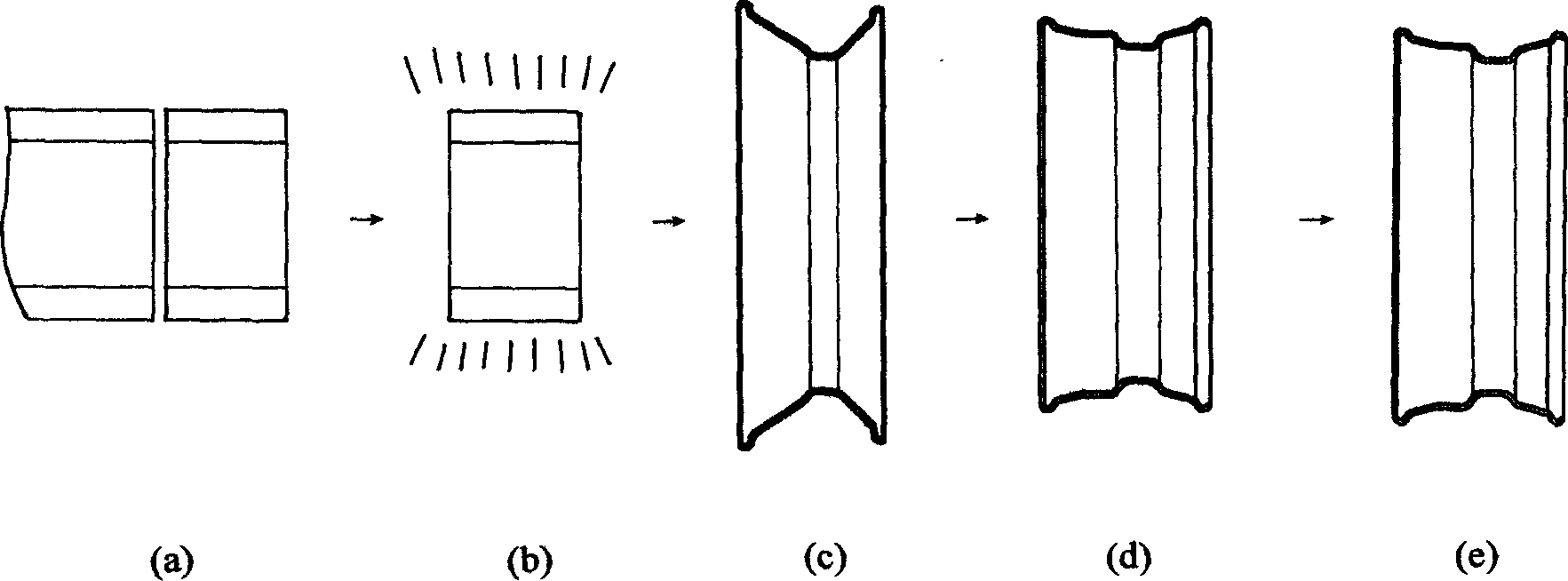

[0008] Such as figure 1 As shown, the steps of this seamless steel rim manufacturing process are: (a) blanking of cast billet tube → (b) heating → (c) rolling → (d) spinning → (e) shaping.

[0009] (a) Cutting: Cut the cast billet pipe into pipe sections with a sawing machine according to the principle of constant volume.

[0010] (b) Heating: The cast steel pipe segment is heated to the forging temperature with a heating furnace.

[0011] (c) Rolling: use a ring rolling machine to roll the heated pipe section to the size of the intermediate billet. During the rolling process, the as-cast microstructure is modified into a forged microstructure. The shape of the intermediate billet is shown in the figure, the inner diameter of the middle part is the same as that of the middle part of the finished product, and the diameters of both ends are larger, and it is bell-shaped.

[0012] (d) Spinning: Use a powerful spinning machine to spin the rolled and expanded intermediate billet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com