Cover plate assembly and mobile terminal comprising same

A technology for mobile terminals and cover plates, which is applied to electrical components, digital data processing components, structural components of portable computers, etc., can solve the problems of high cost of light guide structure materials, high rework rate, and labor-intensive, etc., to save manpower , reduce rework rate, and save material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

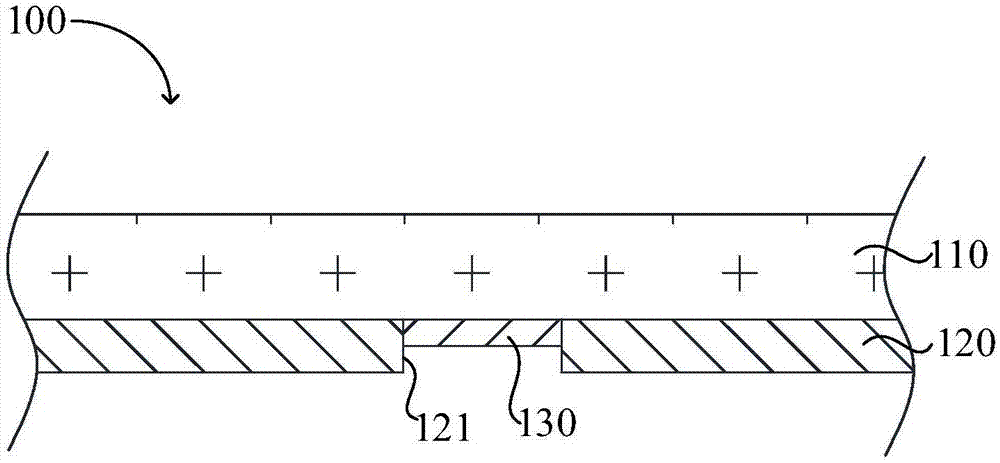

[0045] Such as figure 1 As shown, a cover plate assembly 100 includes a cover plate 110 and an appearance ink layer 120 stacked in sequence. The appearance ink layer 120 is provided with a light exit hole 121 , and a light guide ink layer 130 is provided at the light exit hole 121 .

[0046] In this embodiment, the light guide ink layer 130 fills the light exit hole 121 , and the light guide ink layer 130 is completely located in the light exit hole 121 .

[0047] Such as figure 2 As shown, a mobile terminal 200 includes the cover assembly 100 as described above.

[0048] The cover assembly 100 disclosed in the present invention and the mobile terminal 200 including it use the light-guiding ink layer 130 to replace the light-guiding film in the prior art. The board 110 also has a light guiding function. In this way, there is no need to use light guide film, adhesive, etc., saving material costs; no need to paste light guide film in the assembly stage, saving manpower; no ...

Embodiment 2

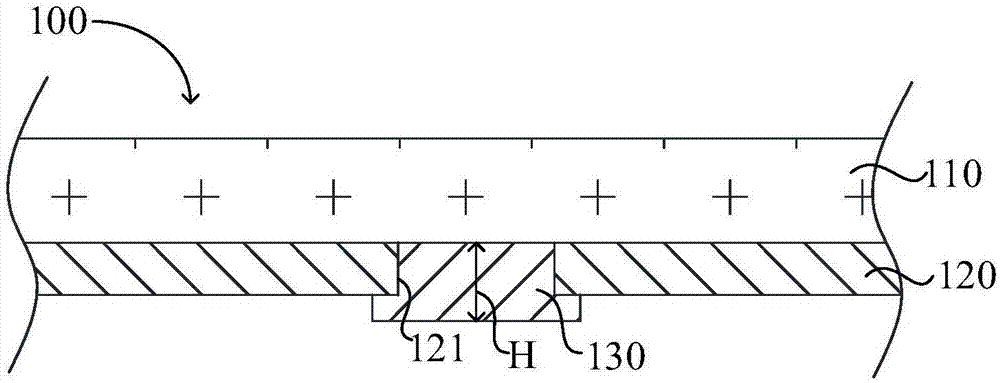

[0050] Such as image 3 As shown, a cover plate assembly 100 includes a cover plate 110 and an appearance ink layer 120 stacked in sequence. The appearance ink layer 120 is provided with a light exit hole 121 , and a light guide ink layer 130 is provided at the light exit hole 121 .

[0051] In this embodiment, the light guiding ink layer 130 completely fills the light exit hole 121 and partially overflows the light exit hole 121 , and the overflowing part of the light guiding ink layer 130 is attached to the appearance ink layer 120 .

[0052] In this embodiment, the appearance ink layer 120 is a black ink layer. In other embodiments, the appearance ink layer 120 can be a white ink layer, a pink ink layer, a yellow ink layer, and the like. The light-guiding ink layer 130 is a white ink layer, which does not change the light color of the indicator light and the backlight, and has a wide range of applications. EM-1004 type white ink can be used. In an alternative embodiment...

Embodiment 3

[0055] Such as Figure 4 As shown, a cover plate assembly 100 includes a cover plate 110 and an appearance ink layer 120 stacked in sequence. The appearance ink layer 120 is provided with a light exit hole 121 , and a light guide ink layer 130 is provided at the light exit hole 121 .

[0056] The ink color of the appearance ink layer 120 is different from that of the light guide ink layer 130 . In order to shield the light-guiding ink layer 130 , improve appearance consistency, and improve user experience, a light-shielding ink layer 140 is provided at the light exit hole 121 , and the light-shielding ink layer 140 is located between the cover plate 110 and the light-guiding ink layer 130 . The visible light transmittance of the light-shielding ink layer 140 is greater than zero.

[0057] In this embodiment, the light-shielding ink layer 140 fills part of the light-emitting hole 121 , and the light-shielding ink layer 140 is completely located in the light-emitting hole 121 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com