Method and device for mounting ultralong air-float guide rail

A technology of air-floating guide rail and installation method, which is applied to the parts of instruments, instruments, supporting machines, etc., can solve the problems of poor long-term stability and thermal stability, no technical solutions, etc., and achieve compact structure, good air tightness, seam leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

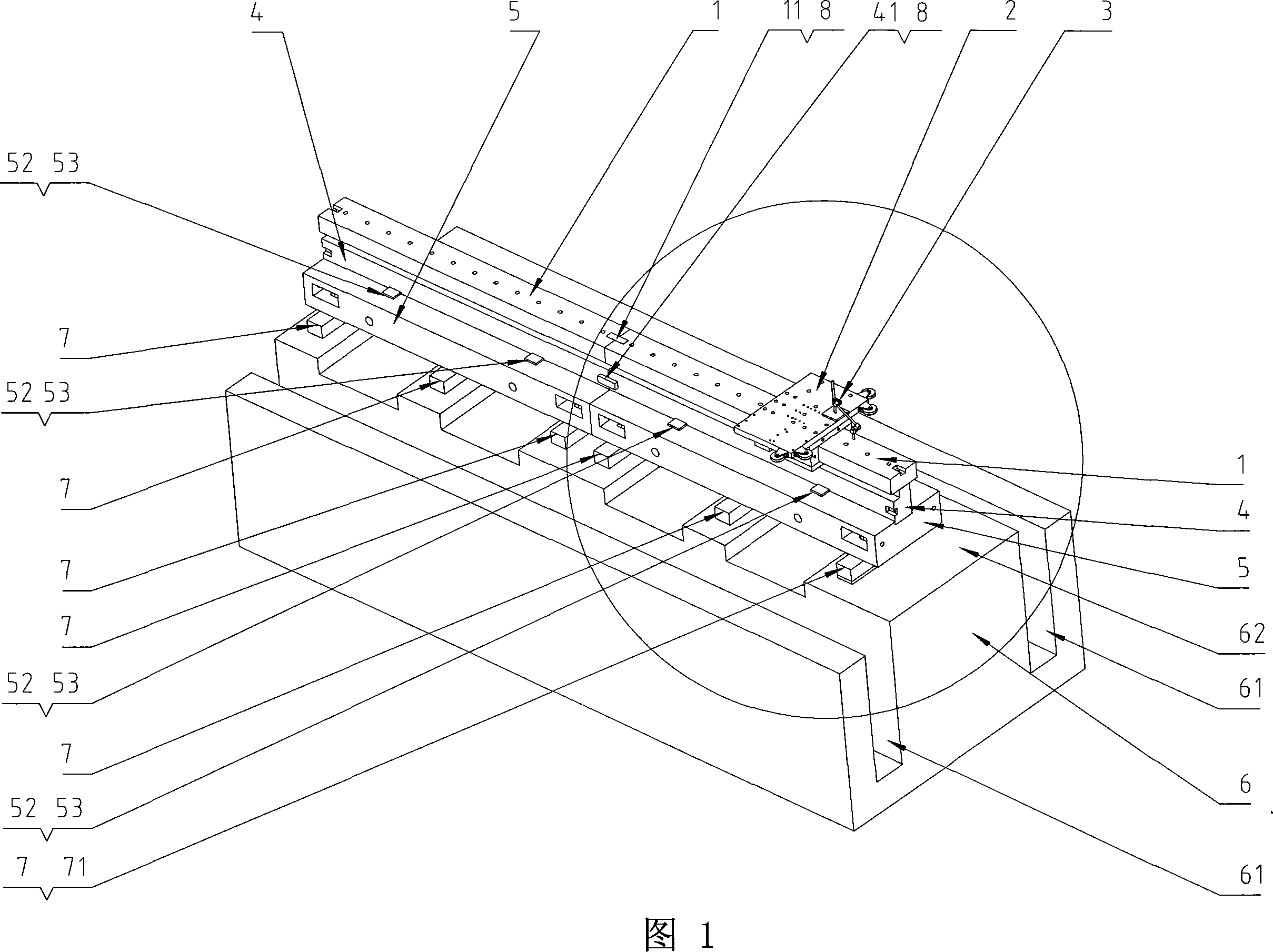

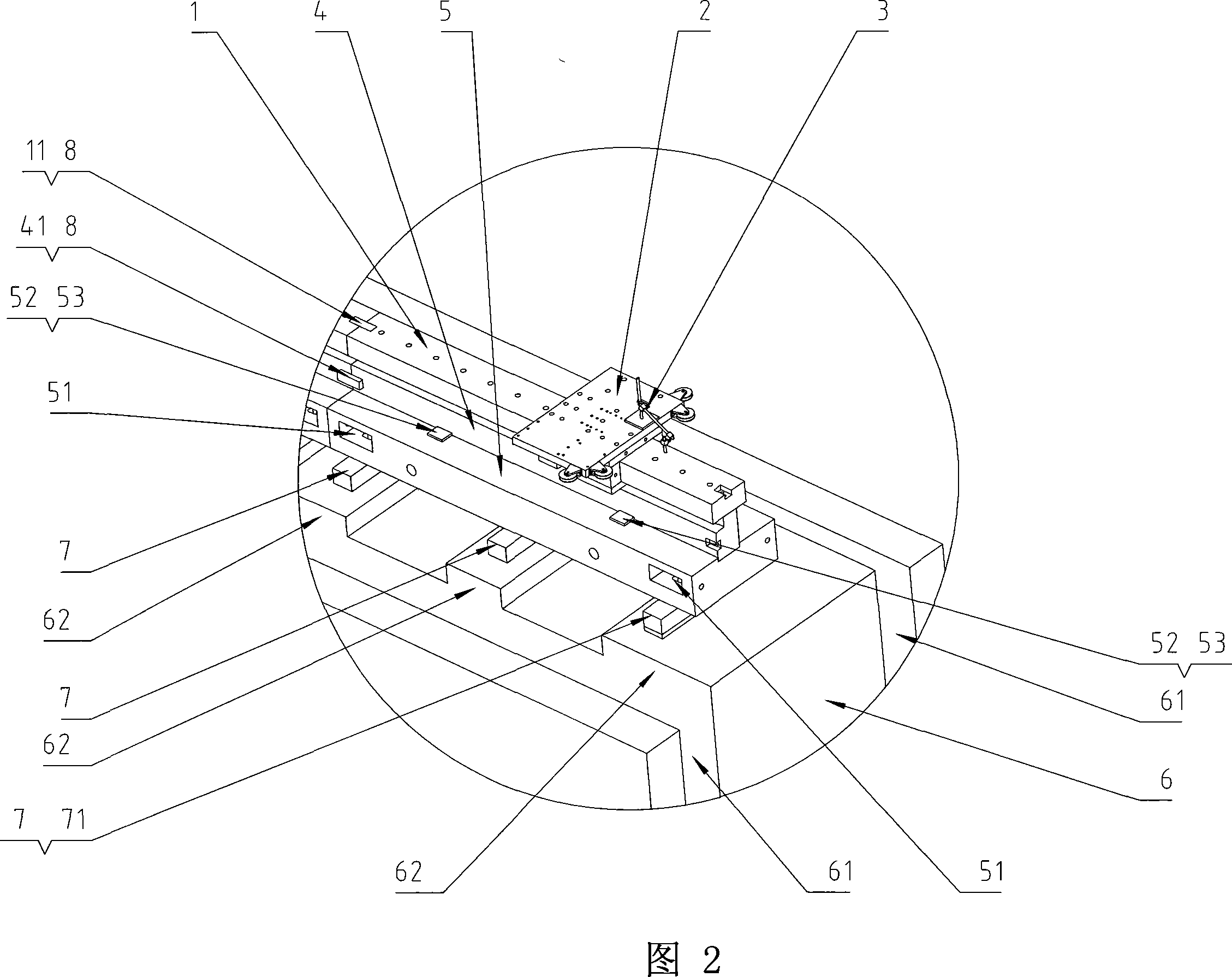

[0022] The installation method of the ultra-long air-floating guide rail of the present invention is that the first section guide rail 1 is installed and positioned, a mobile measuring platform 2 that can slide along the guide rail is installed on the guide rail 1, and a measuring device 3 is installed on the mobile measuring platform 2. The other guide rail 1 is connected with the first guide rail 1, slide the mobile measuring platform 2 to the joint of the two guide rails 1, measure the straightness of the upper surface and both sides of the joint of the two guide rails 1 through the measuring device 3, and press Calibrate according to the requirements of installation accuracy, and then connect the next section of guide rail 1 according to the above method until the last section of guide rail 1 is installed. This method of real-time control of installation accuracy can ensure the accuracy of the super-long air-floating guide rail, so that the air cushion will not leak at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com