Rim without inner tyre and manufacturing method thereof

A manufacturing method and wheel rim technology, applied in the field of wheel manufacturing, can solve the problems of high difficulty, labor and time-consuming welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

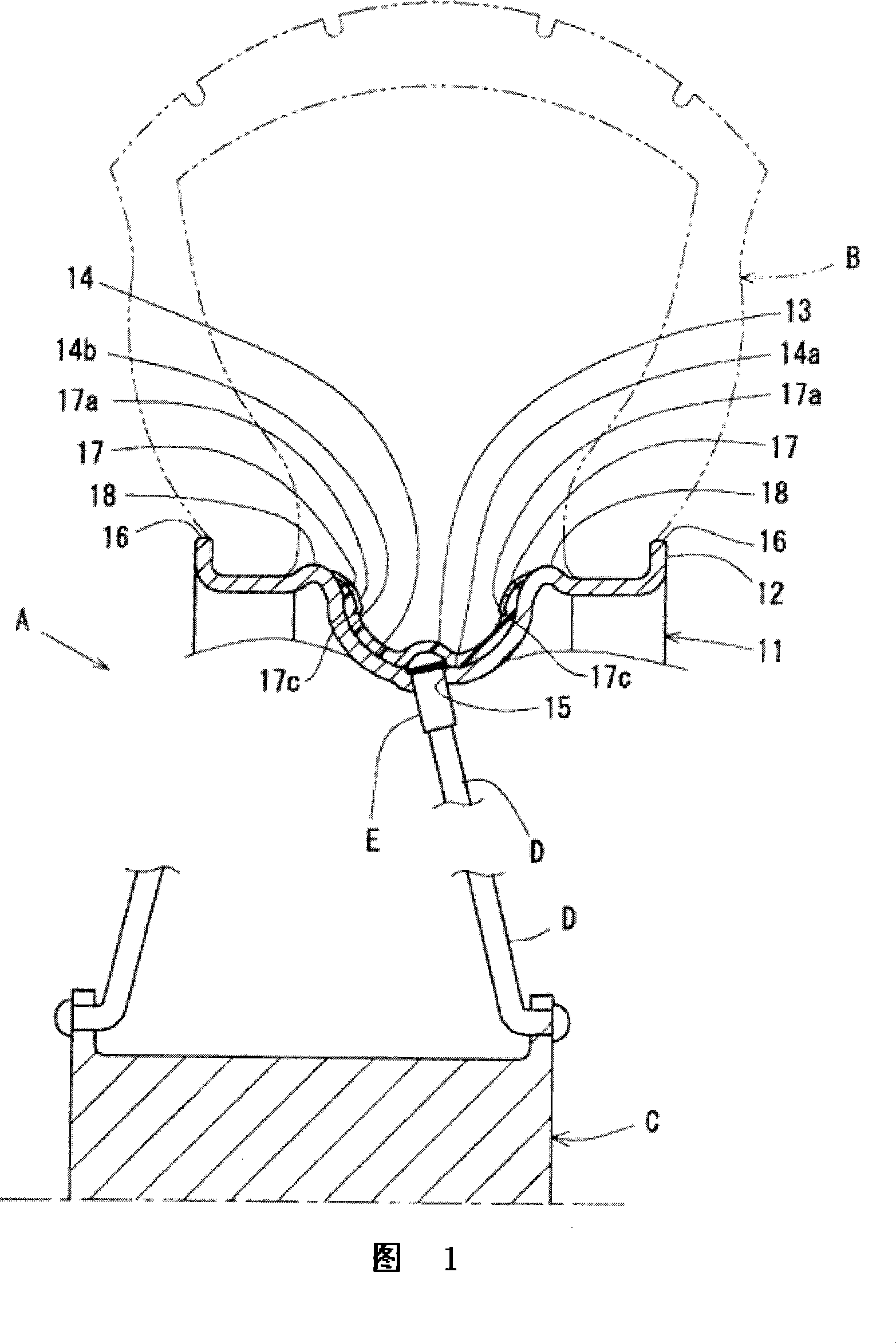

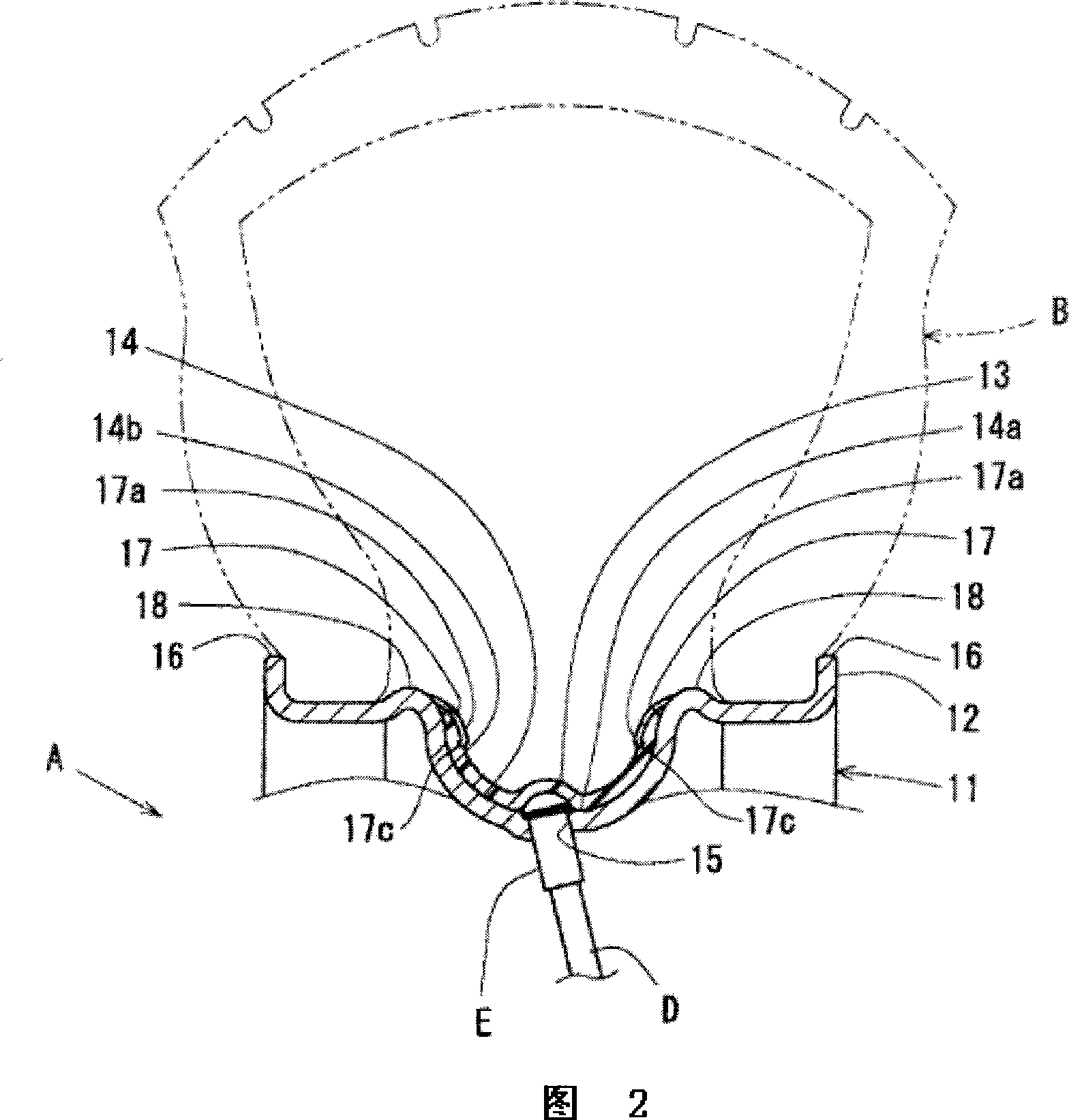

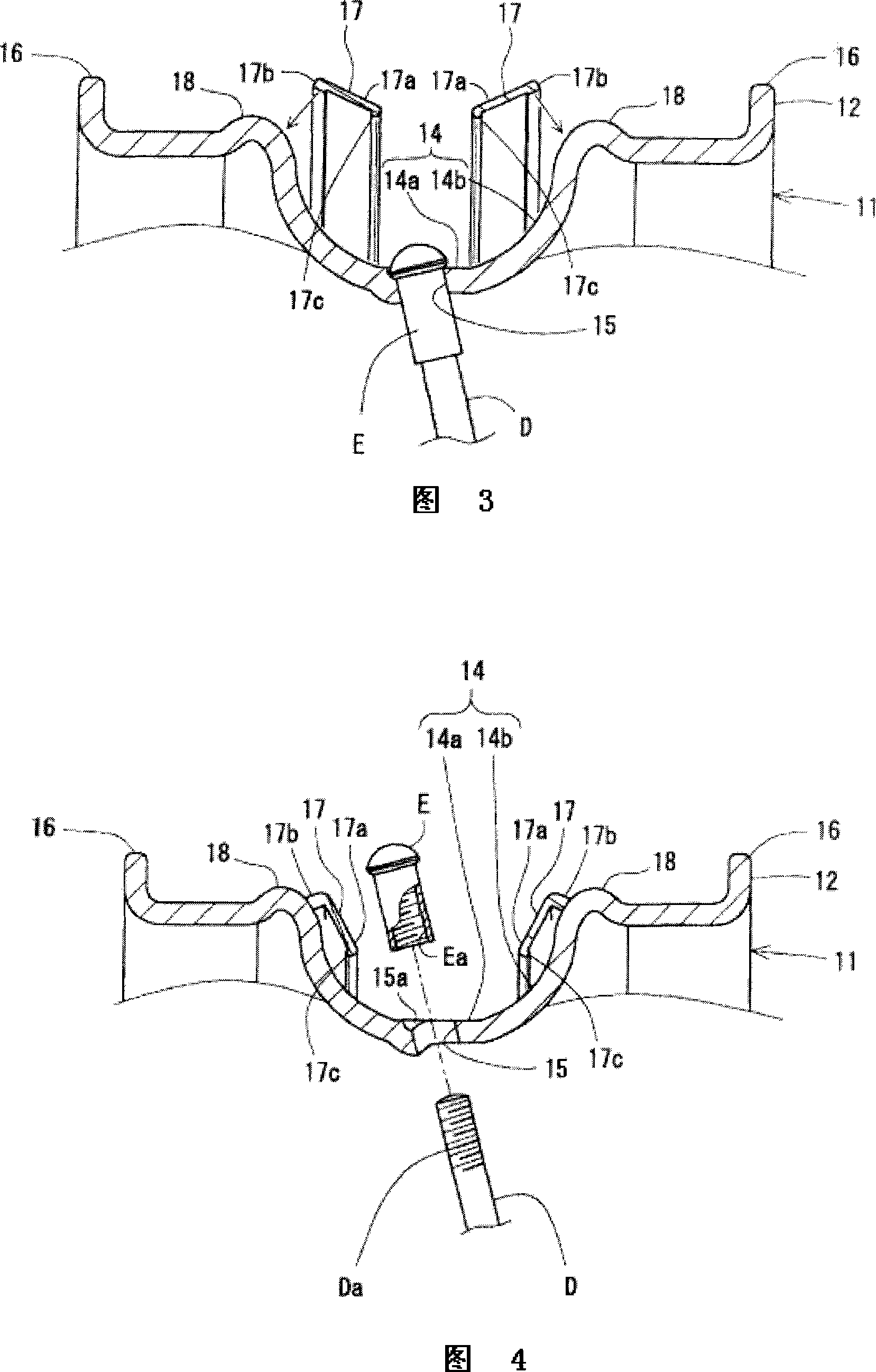

[0023] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

[0024] In Fig. 1 and Fig. 2, the tubeless rim A of the present invention consists of a steel rim 11, a hub C, and steel wire spokes D which are arranged between the steel rim 11 and the hub C and are arranged radially as a whole. The steel rim 11 The part drawn with a dotted line above is the tubeless tire B, which is characterized in that the steel ring 11 is composed of a steel ring main body 12 and a sealing material 13, wherein: the steel ring main body 12 is made of a hard metal material, and is arranged in the middle The groove 14 and the left and right flanges with flanges 16 on both sides of the groove 14 are formed. The groove 14 is composed of a ring-shaped groove bottom 14a and a ring-shaped left and right side walls 14b. 14a is provided with a limit installation hole 15 for steel spokes, and an outwardly convex curved portion 18 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com