Air leakage detection device for infusion tube

A technology for detection devices and infusion tubes, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, can solve the problems of low efficiency and low accuracy of manual detection, and achieve high efficiency, Reduce the possibility of manual misjudgment, the effect of compact operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following embodiments are only explanatory and do not constitute a limitation of the present invention. All modifications or variations made without departing from the spirit of the present invention belong to protection scope of the present invention.

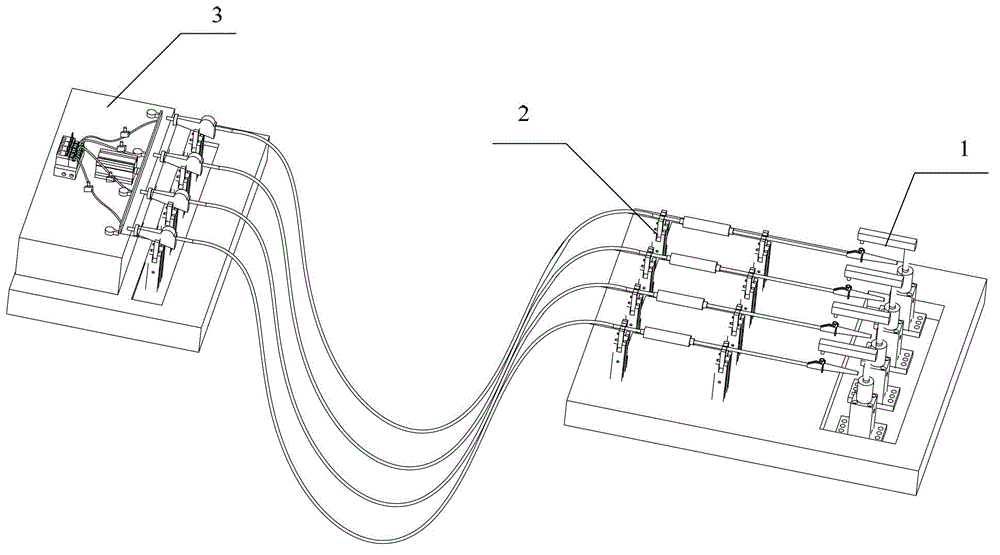

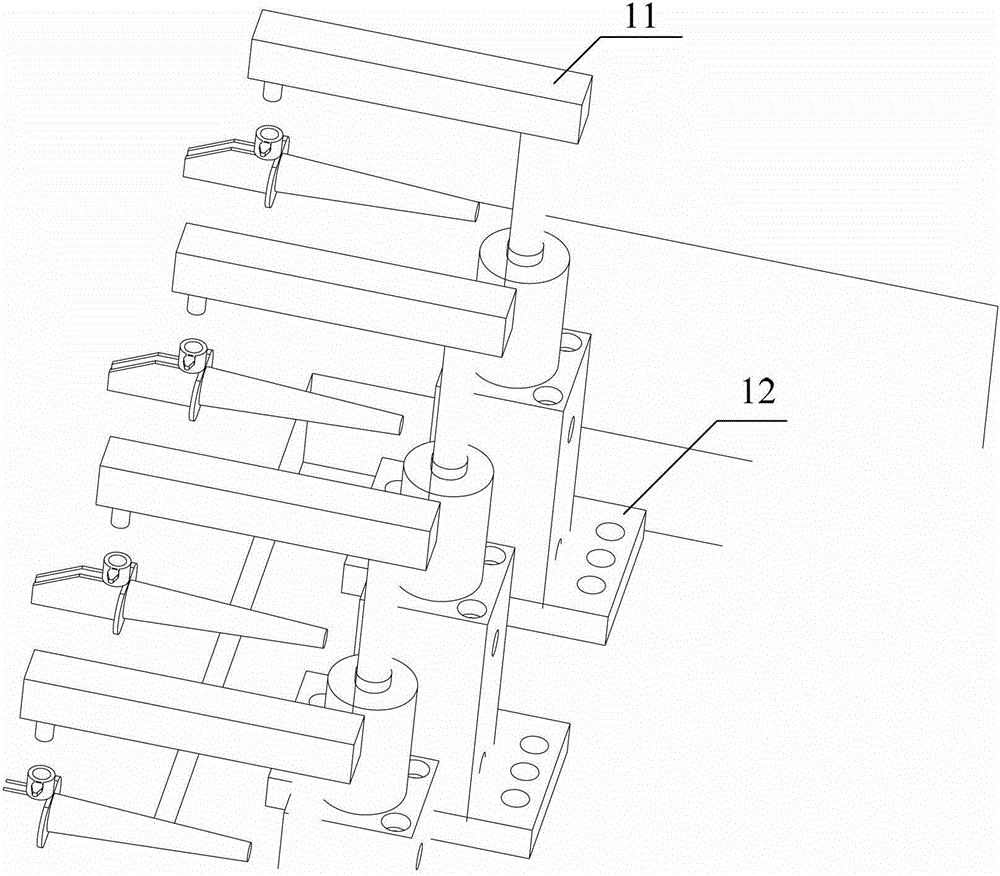

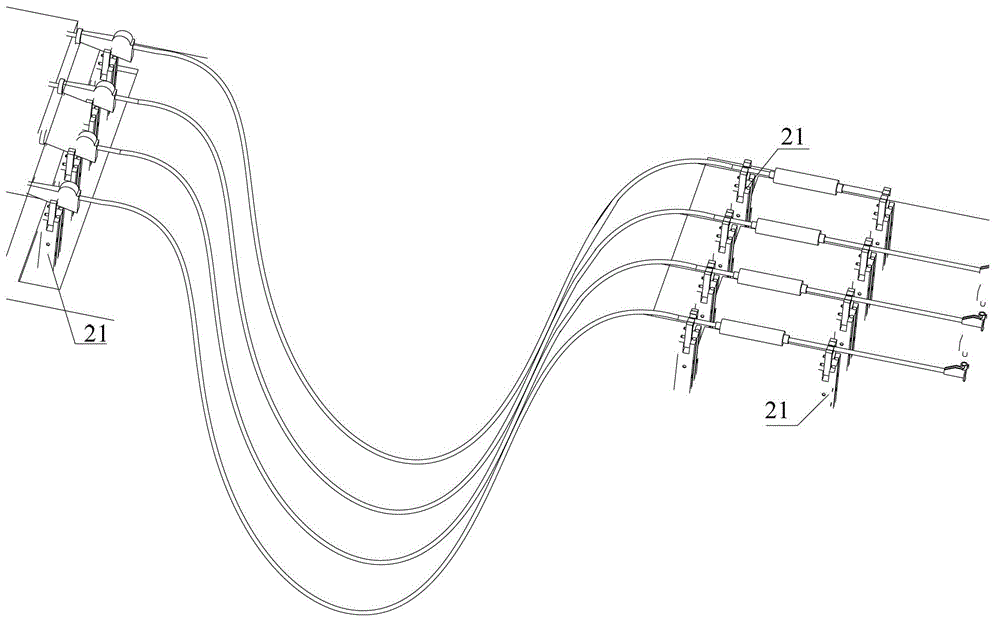

[0026] like figure 1 As shown, the gas leakage detection device of the embodiment of the present invention includes a sealing part 1 , a clamping part 2 and an air delivery part 3 . Among them, the sealing part 1 is used to complete the sealing of the ventilating end of the infusion tube needle, the clamping part 2 is used to tighten and fix the infusion tube to ensure that the position of the infusion tube is fixed on the test workbench during the entire test process, and the gas delivery part 3 is used to fix the infusion tube. The other end of the infusion tube is pressurized wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com