Drill hole spray safety protection system

A technology of safety protection and drill-and-spray, applied in safety devices, dust-proof, earth-moving drilling, etc., can solve the problems of coal powder blocking drilling, hindering drilling progress, gas control work lag, etc., and achieving high negative pressure continuous pumping. The effect of mining and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

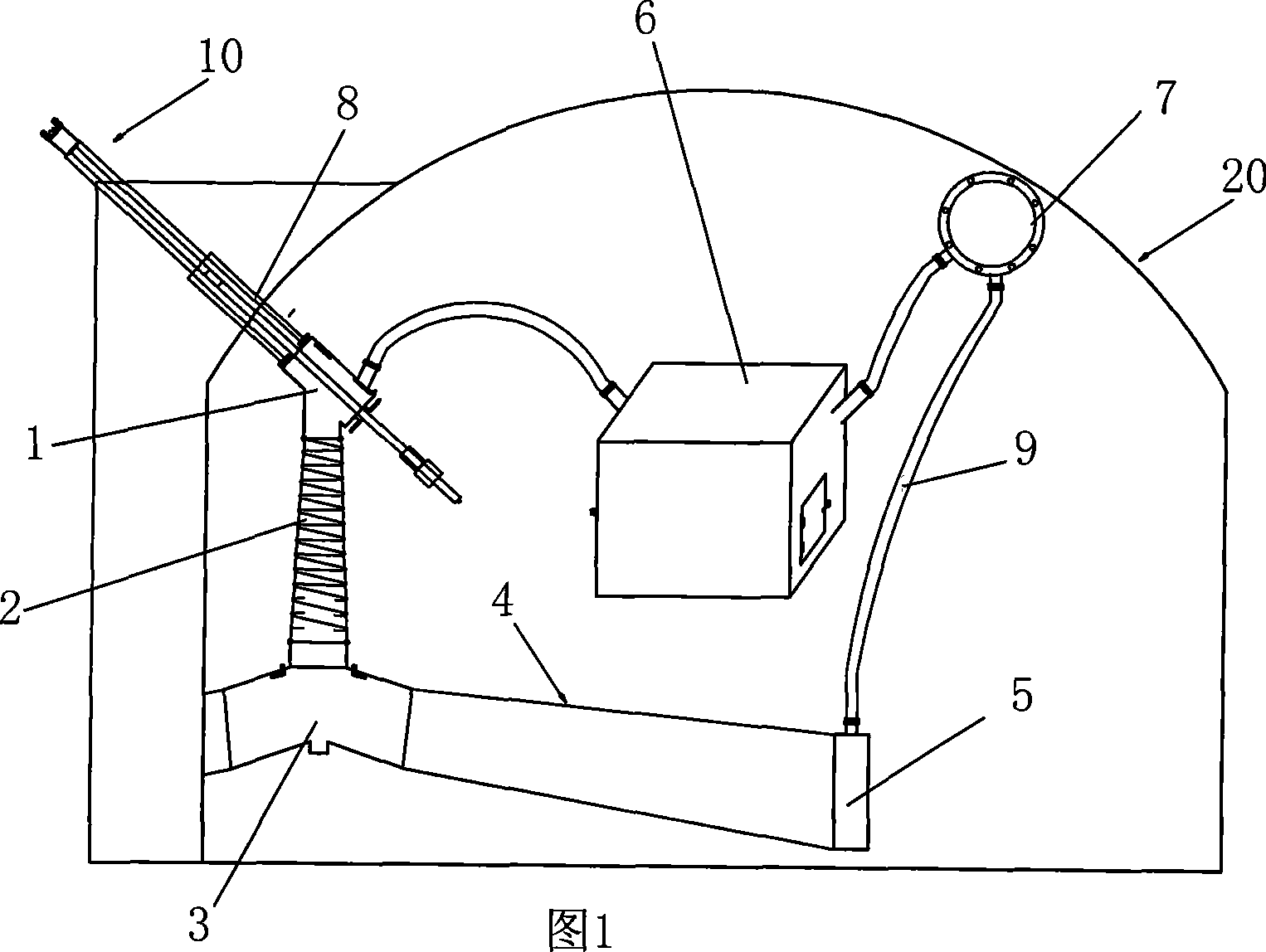

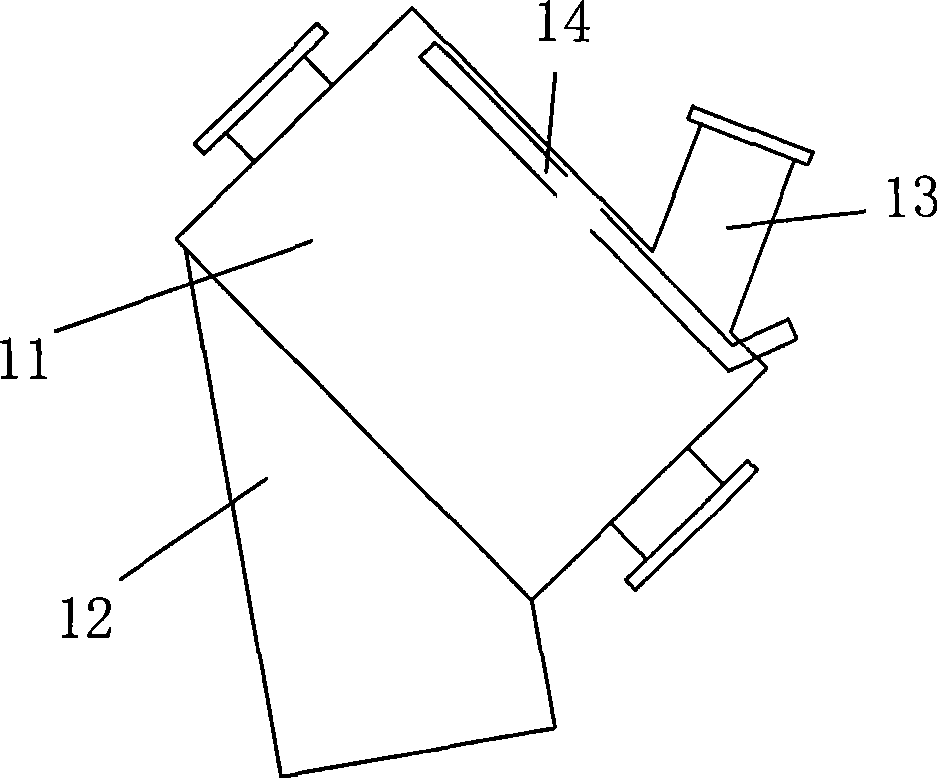

[0028] See Figure 1, figure 2 , the orifice multi-way device 1 is provided with a drill pipe passage 11 on it, and a sprayer 14 is arranged on the inner side wall of the drill pipe passage 11; Downward; the drainage channel 13 is connected to the upper side of the drill pipe channel 11 as a branch, and the outlet is upward. When a spray hole occurs, the coal powder and gas are divided according to their respective channels in the multi-way device of the orifice, and sprayed to reduce dust, so as to ensure the normal footage of the drilling rig.

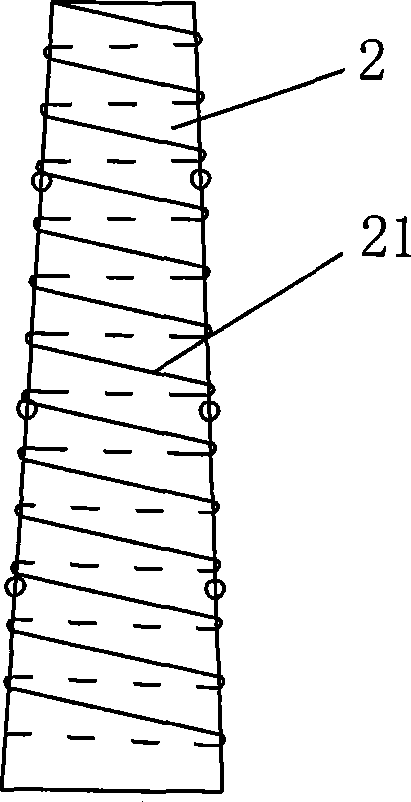

[0029] See Figure 1, image 3 , a telescopic connecting pipe 2 is set, which is made of high-strength filament fiber cloth, and flexible steel wire 21 is arranged in a spiral shape by sewing in the interlayer of high-strength filament fiber cloth; the upper opening of the connecting pipe 2 is small, and the bottom opening is large. Its upper port is connected with the pulverized coal channel 12 in the orifice multi-way device 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com