Device and method for measurement while drilling of ground stress

A technology of measurement while drilling and in-situ stress, which is applied in the direction of measurement, earthwork drilling, wellbore/well components, etc., which can solve the problems of unusability and achieve the effects of short time, convenient use and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

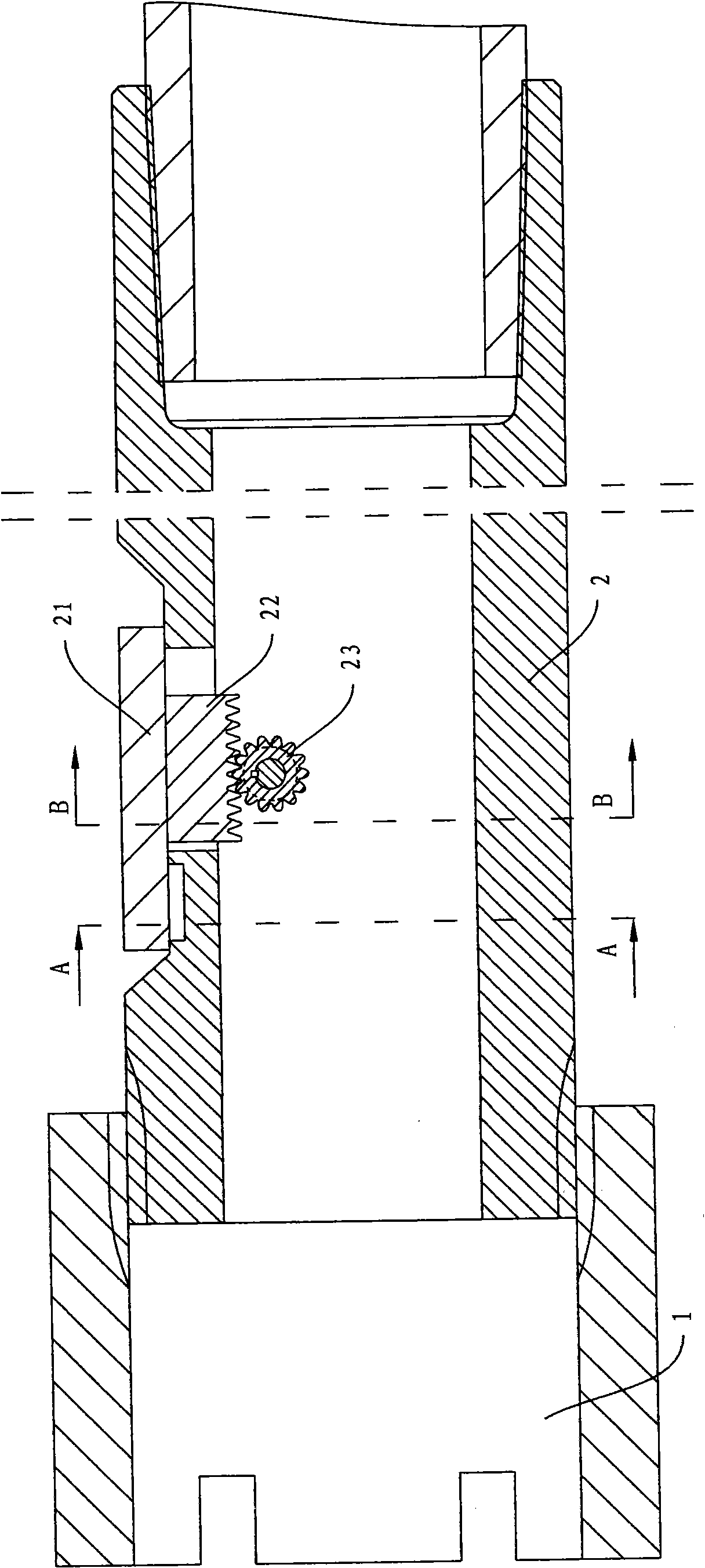

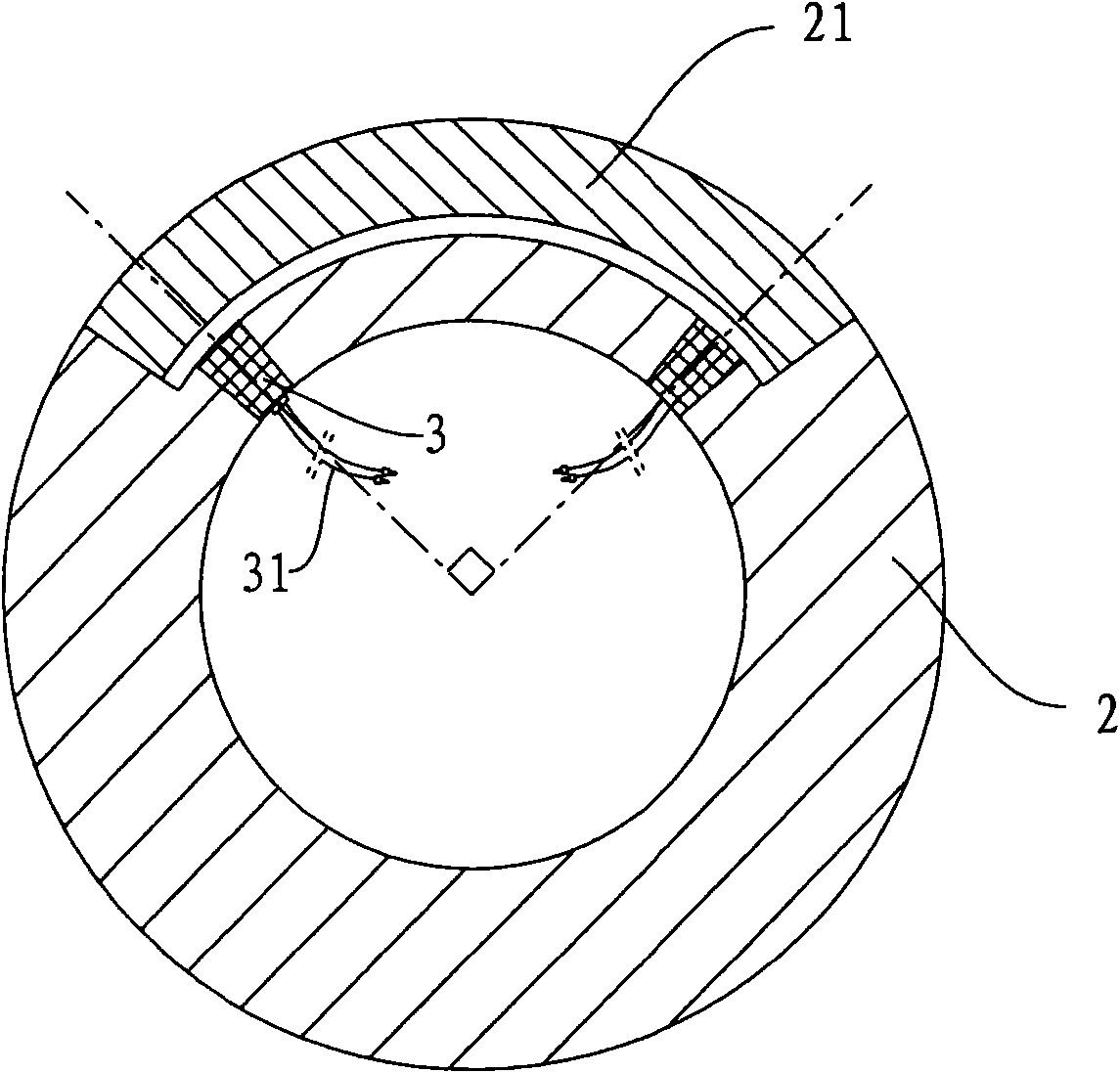

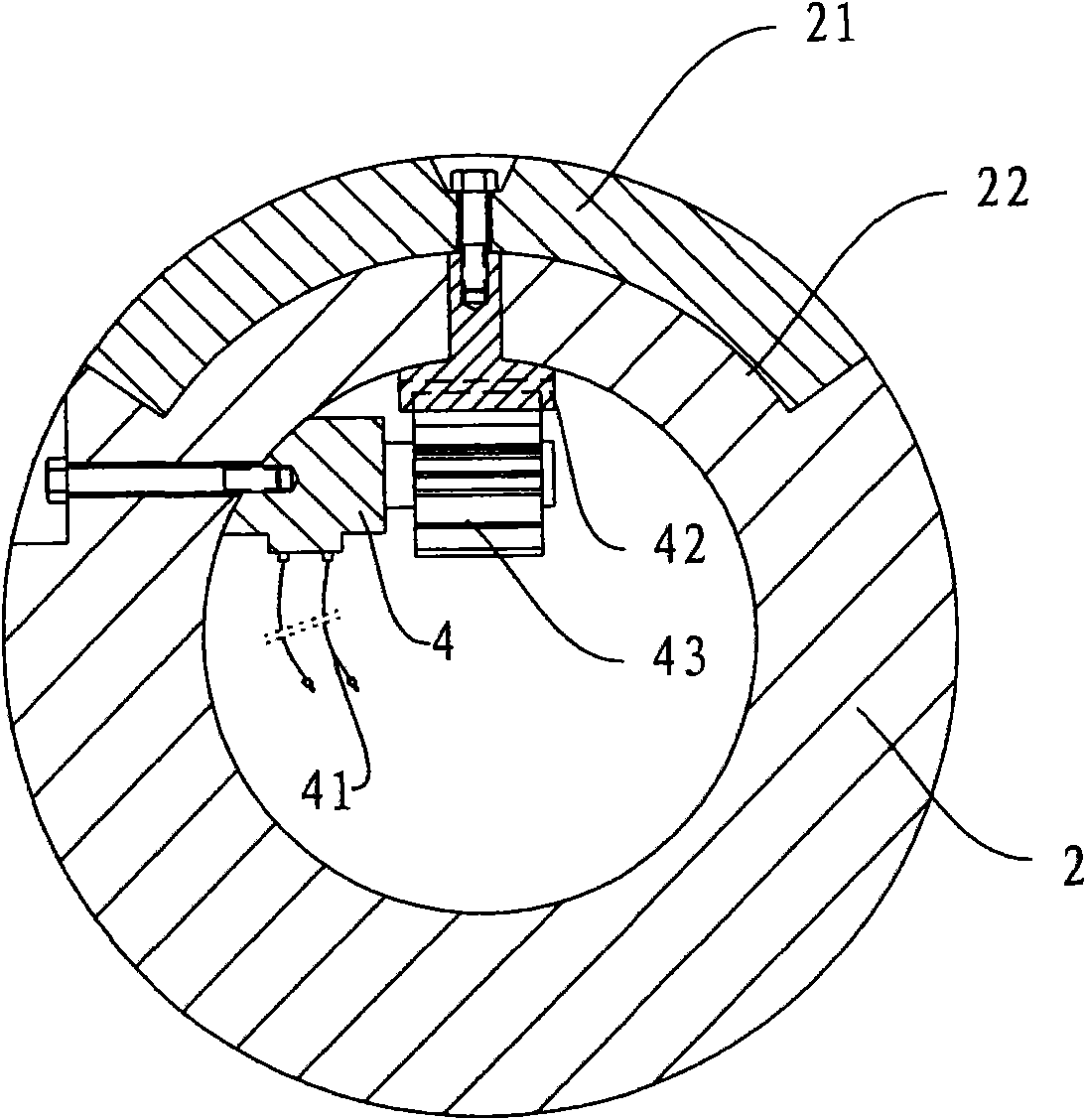

[0023] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a kind of in-situ stress measurement-while-drilling device, including a drilling machine (not shown in the figure), a drill pipe 2 and a drill bit 1, and the side wall close to the drill bit 1 on the drill pipe 2 connected to the drill bit 1 A pressure sensor 3 is arranged on the drill pipe 2, and a slide cover 21 for protecting the pressure sensor 3 is also provided on the drill pipe 2. When the slide cover 21 slides open, the pressure sensor 3 can be exposed. When the slide cover 21 is closed, the pressure sensor 3 can be covered by the slide cover. 21 is closed, and the sliding cover 21 realizes sliding opening and closing by a driving device. There are two pressure sensors 3 with an included angle of 90°, which can measure the ground stress in X and Y directions. Each pressure sensor 3 is provided with a data line 31, and the connection terminal is a plug mode, which is conveni...

Embodiment 2

[0026] An embodiment of the present invention provides a method for measuring in-situ stress while drilling, comprising the following steps:

[0027] 1) Select the position that needs to be measured on the downhole working face, and use the in-situ stress measurement-while-drilling device described in Embodiment 1 to construct the borehole according to the designed borehole inclination, azimuth, depth and aperture. At this time, keep the slide cover 21 is closed;

[0028] 2) Stop the machine after drilling the hole, separate the drill pipe 2 from the drilling rig, then connect the pressure sensor 3 directly to the signal processing device (not shown in the figure), and then connect various other circuits, and then pass through the driving device of the slide cover 21 Sliding the slide cover 21 to expose the pressure sensor 3;

[0029] Specifically, the sliding cover 21 is driven to slide open by controlling the motor 4 to drive the gear 43 and the rack 42 mechanism.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com