Oxygen-free drying and upgrading system of lignite and lignite drying process

A lignite drying technology, applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., to achieve the effect of reducing emissions and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

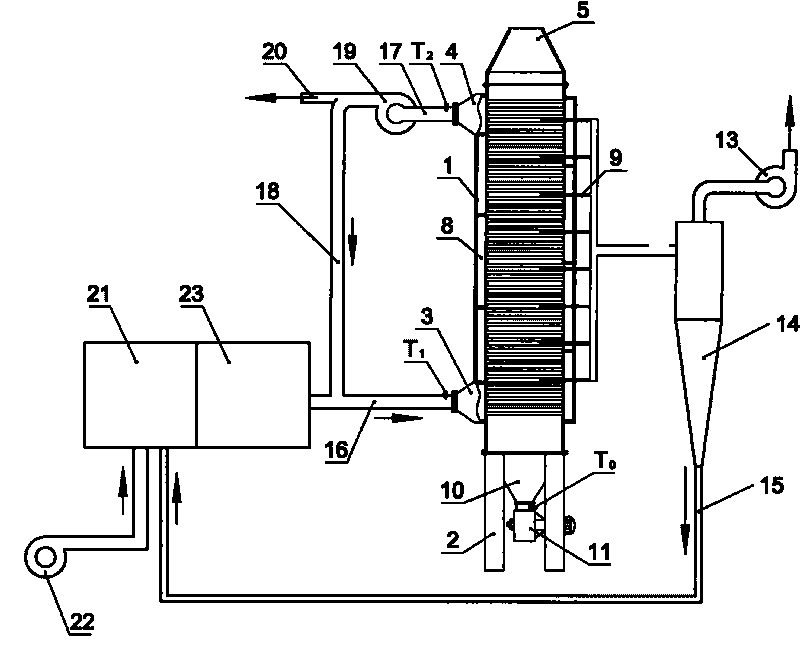

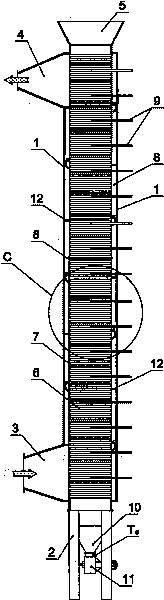

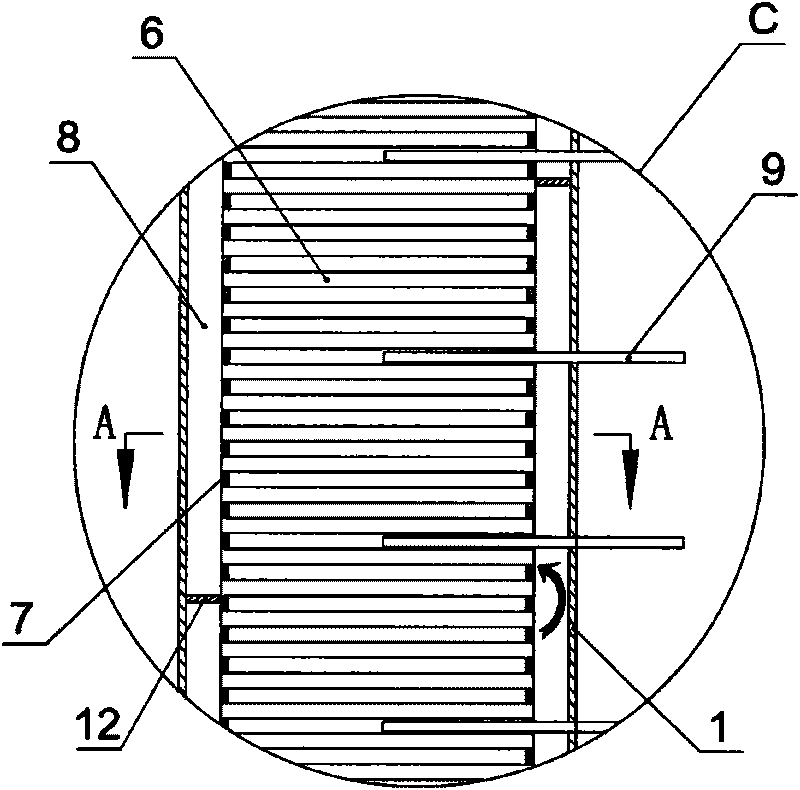

[0041] Embodiment one: see figure 1 , figure 2, diagram 2-1 , Figure 2-2 , a lignite anaerobic drying and upgrading system, including the coal anaerobic drying device described in Embodiment 1, and also includes a heating system, the heating flue gas output pipe of the heating system communicates with the inlet pipe 16 of the coal anaerobic drying device, during drying The flue gas inlet pipe and the flue gas outlet pipe of the device are respectively equipped with thermometers T 1 , T 2 , there is a discharge valve and a thermometer T at the discharge port at the bottom of the drying device 0 A steam pipe 9 is also provided inside the drying cylinder of the coal anaerobic drying device, and the steam pipe is drawn out of the drying device, and the steam pipe is drawn out of the drying device and directly discharged.

[0042] At the same time, a fork pipe (return pipe) 18 is provided on the air outlet pipe 17 of the coal anaerobic drying device, and the fork pipe 18 an...

Embodiment 2

[0054] Embodiment 2: The meaning is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is: control the flue gas input temperature T 1 400~800℃, flue gas output temperature T 2 100-250°C.

Embodiment 3

[0055] Embodiment three: the meaning is basically the same as that of embodiment one, and the similarities will not be repeated. The difference is: for the lignite drying and upgrading, the lignite discharge rate is controlled, and the lignite final heating temperature T is maintained. 0 It is between 200 and 350°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com