Loose blasting gas extraction technology of horizontal branch well of coal seam floor

A technology for horizontal branch wells and coal seam floors, which is applied in the direction of gas discharge, mining fluid, directional drilling, etc., and can solve problems such as delays in underground production, danger of blind blasting, and gas outbursts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

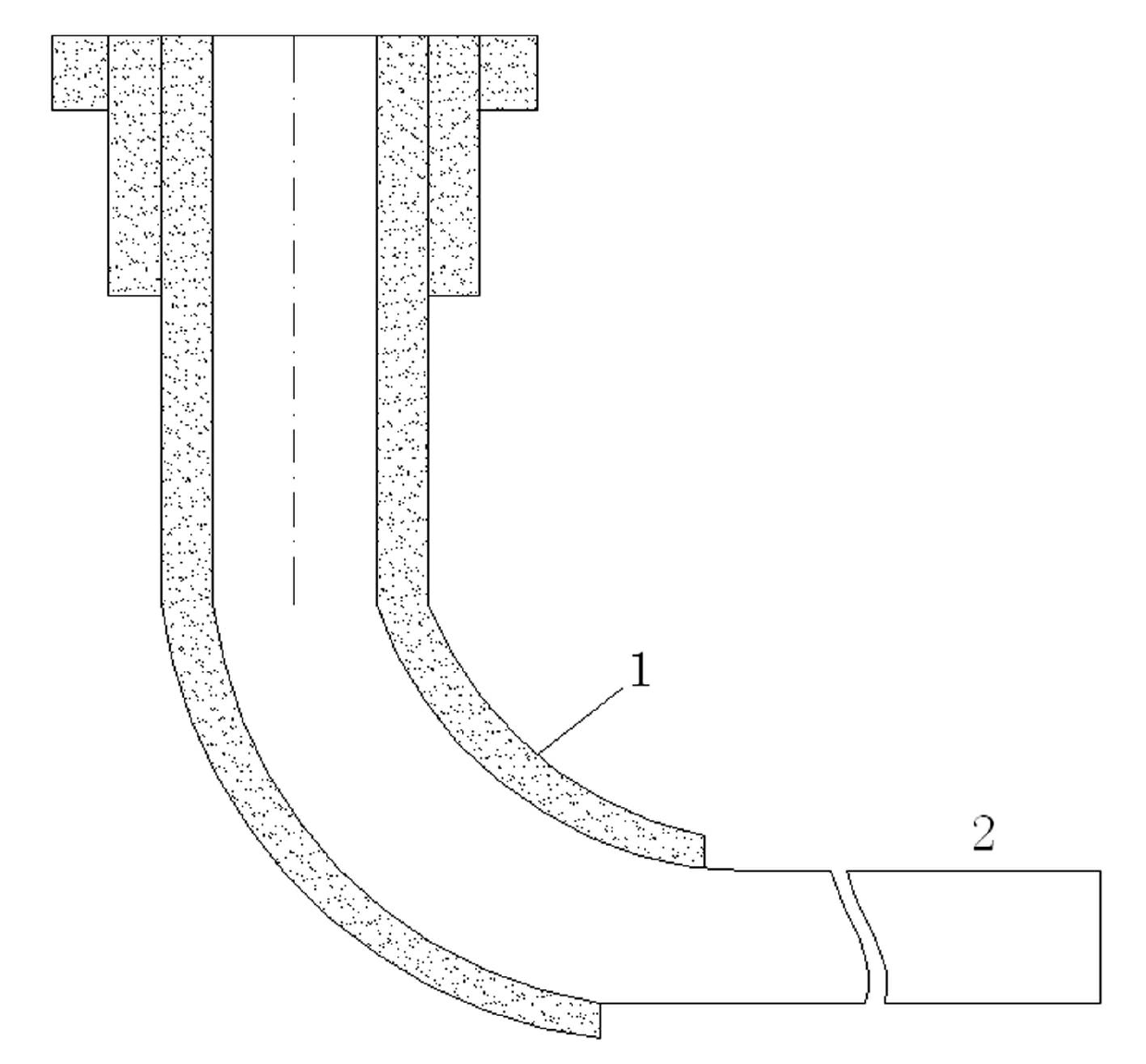

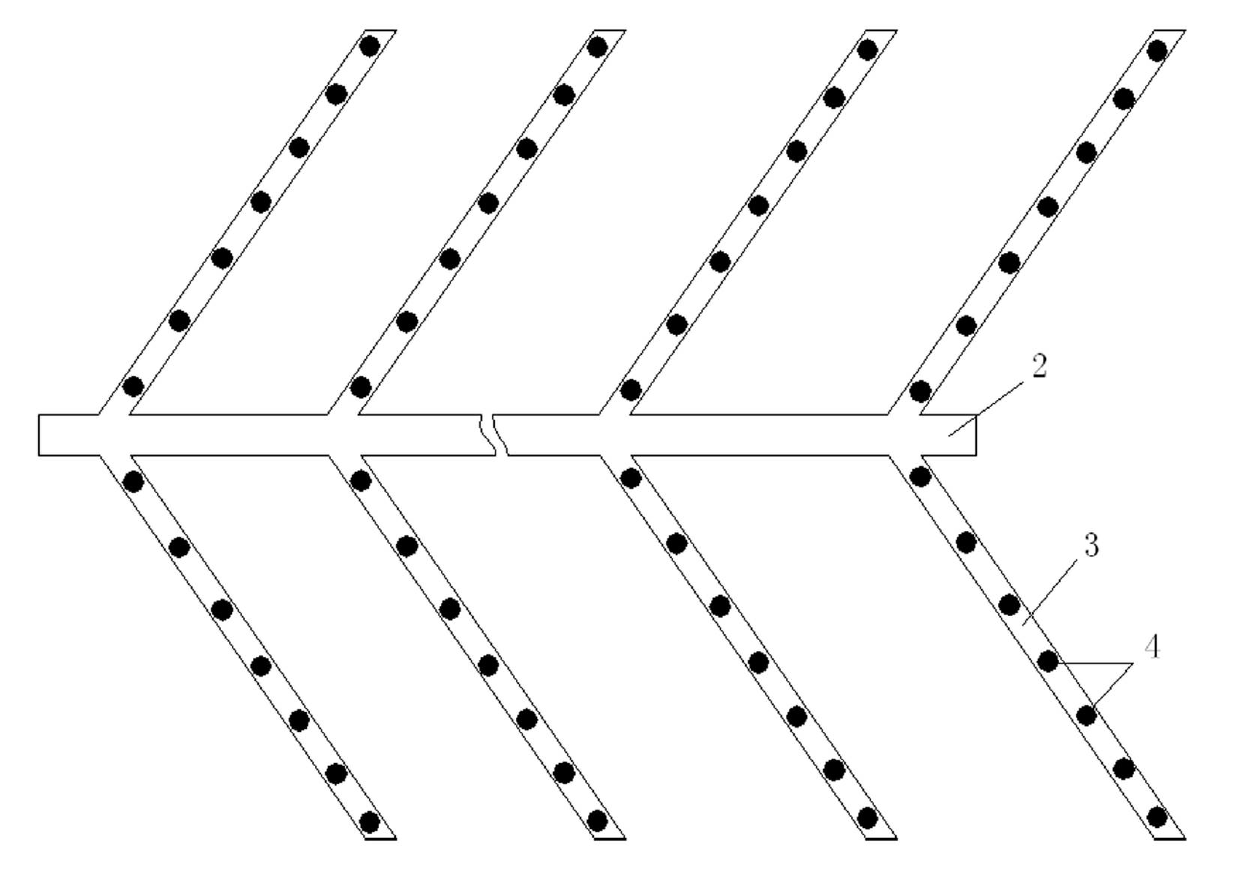

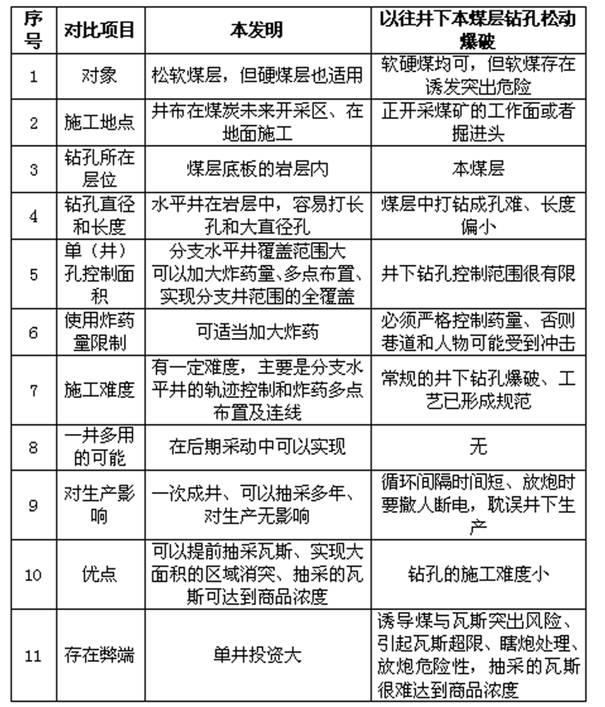

[0016] Example: such as figure 1 , figure 2 As shown, the gas drainage technology of horizontal branch wells on the coal seam floor by loose blasting includes the following steps in sequence: (1) Select gas content greater than 8 m 3 / t and the coal reservoirs with firmness coefficient f<0.5; (2) Select the layers where the main horizontal well 2 and branch horizontal well 3 are located at 1-2 m from the coal seam floor; (3) According to the layers of the main horizontal well section, take For the purpose of achieving large-radius build-up, where build-up radius 1 is between 250-500 m, determine the location of the surface wellhead and build-up point; (4) The wellbore structure adopts a three-opening structure, with main horizontal well 2 and branch horizontal well 3 Open-hole wells are used; (5) Main horizontal wells and branch horizontal wells are constructed in the selected floor strata; (6) Explosive points 4 are arranged in the branch horizontal well sections, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com