High-pressure water jet system and method for drilling and enlarging holes on coal bed

A high-pressure water jet and high-pressure jet technology, which is applied in the direction of liquid/gas jet drilling, drill bits, drilling equipment, etc., can solve the problems of difficult drilling along the bedding, small aperture of the coal seam section of the drilling through the bedding, and reduce operating costs , Avoid stuck and clamped drills, shorten the effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the examples are only to illustrate the present invention, not to limit the protection scope of the present invention.

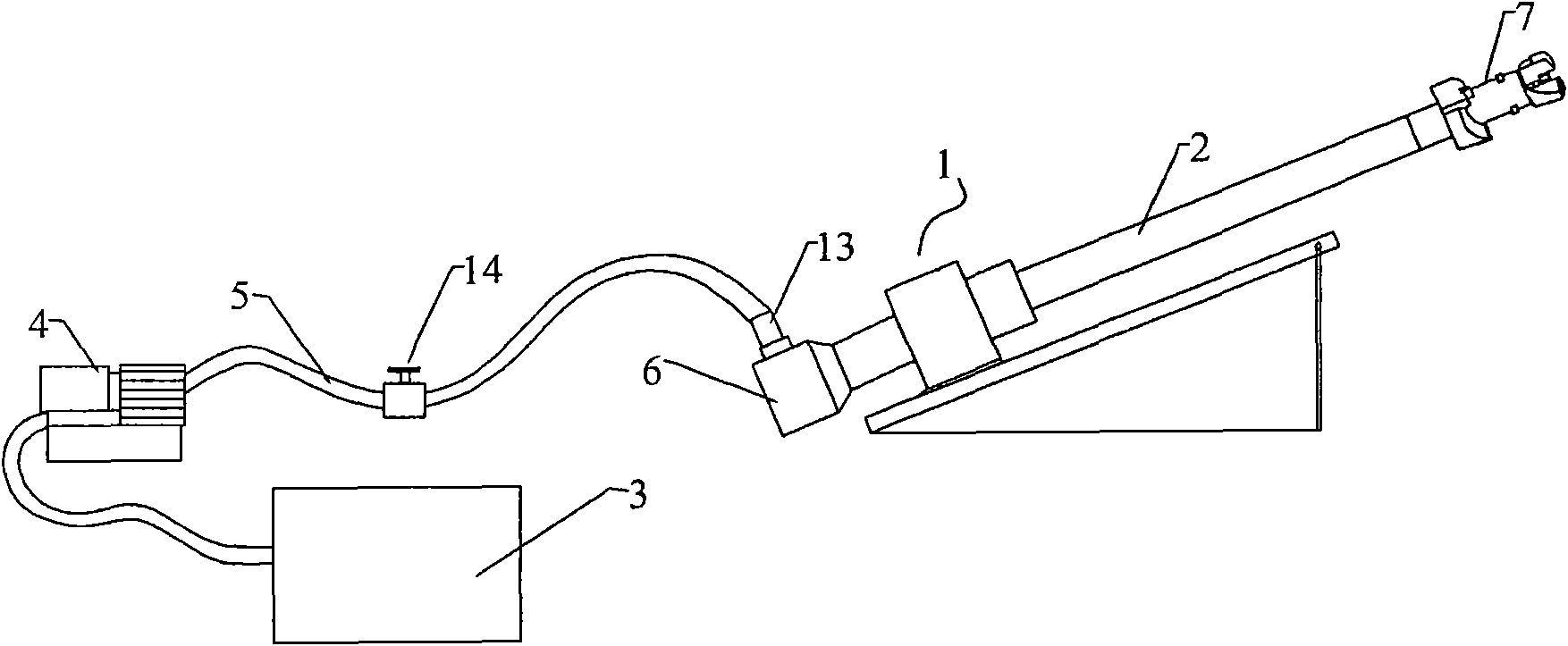

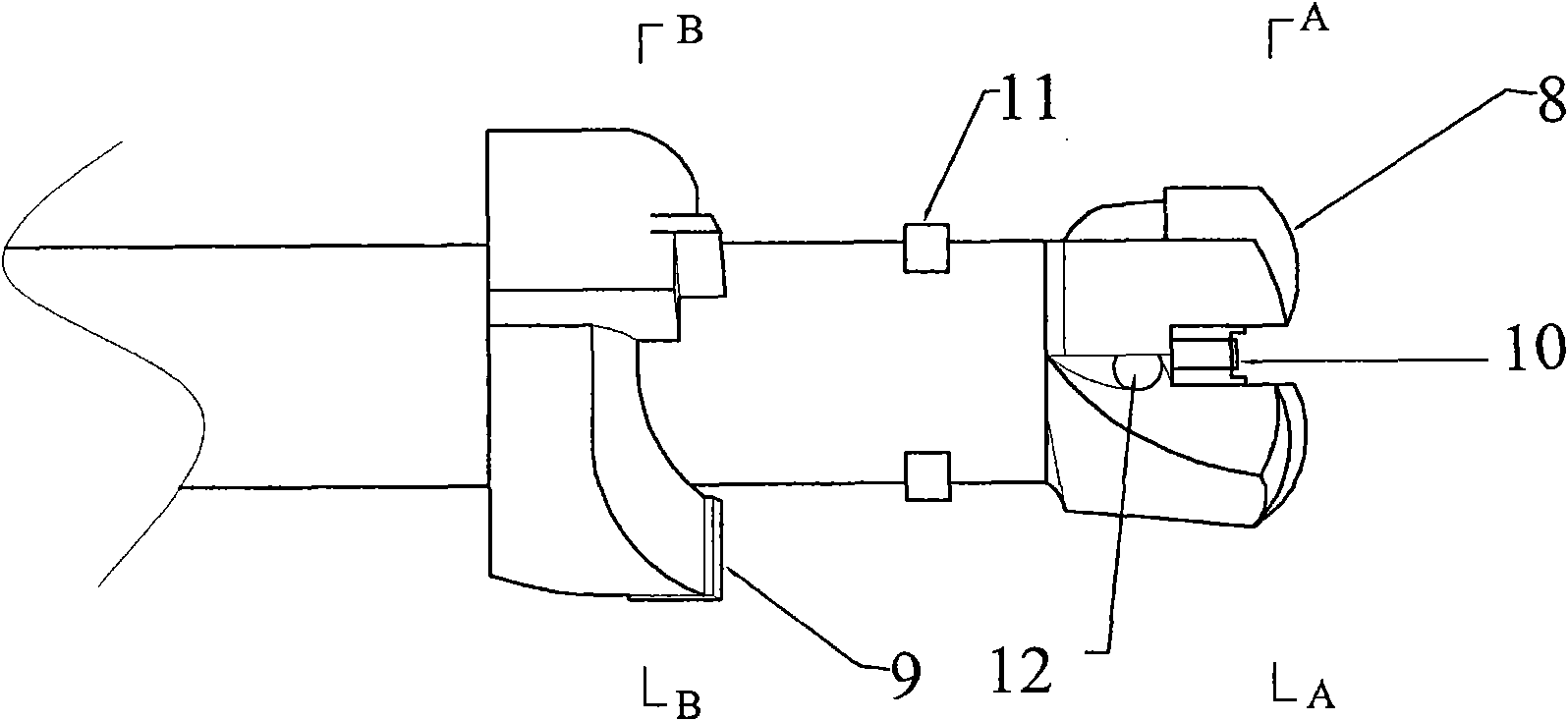

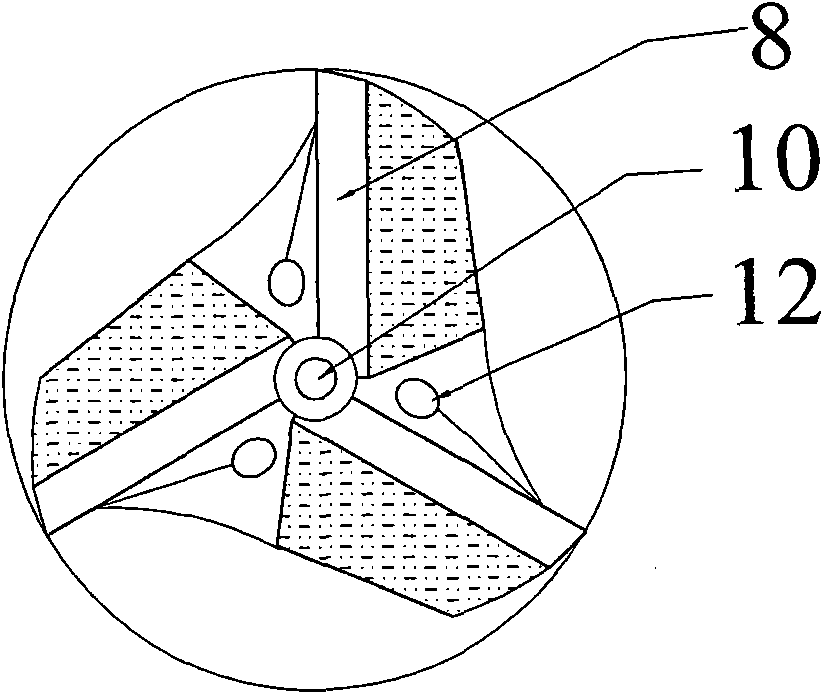

[0033] 1-drilling rig system; 2-high-pressure sealed drill pipe; 3-water storage tank; 4-high-pressure water pump; 5-high-pressure rubber hose; 6-rotary sealing device; Rear increased vane; 10-straight nozzle; 11-side nozzle; 12-oblique nozzle; 13-quick connector; 14-control valve.

[0034] Such as figure 1 As shown, the high-pressure water jet coal seam drilling and reaming system of the present invention includes a drilling rig 1. The drilling rig 1 includes a hydraulic pump, a console and a drilling rig body. The drilling and reaming system also includes a high-pressure water jet system. The high-pressure water jet system includes sequentially Connected water storage tank 3, high-pressure water pump 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com