Feeding method and device for hole protecting pipe for soft coal seam gas extraction hole

A technology for gas drainage and soft coal seam, applied in gas discharge, safety devices, mining equipment, etc., can solve the problems of residual coal chips in drilling, difficult to feed into local collapsed holes, etc., to achieve the effect of ensuring smooth passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

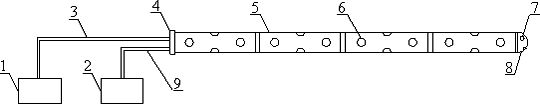

[0026] Embodiment 1: When the borehole protection pipe is sent into the borehole, air with a certain pressure is pressed in to discharge the coal dust in front. The method scheme includes the following steps:

[0027] a. Use epoxy resin glue to fill the sieve holes of the perforated pipe, and install a vent on the top of the first section of the perforated pipe.

[0028] The hemispherical protective cover of the hole; a reducing joint is installed at the end of the last section of the hole protecting pipe, and the reducing joint is connected to the air intake pipe, and the air intake pipe is connected to the air compressor.

[0029] b. After the epoxy resin is solidified, make the air compressor work, and press air with a certain pressure into the hole protection pipe; send the first section of the hole protection pipe into the gas drainage borehole;

[0030] c. Turn off the air compressor, remove the variable diameter joint, connect the second protective tube to the first pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com