Method for producing moulded coal by oil-rich coal with low-ash low-sulfur low-phosphor and high-heat productivity

A high calorific value, briquette technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of waste of oil and gas resources, environmental pollution, irritation, etc., and achieve the effect of reducing smoke and dust emissions, reducing pollution emissions, and less pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

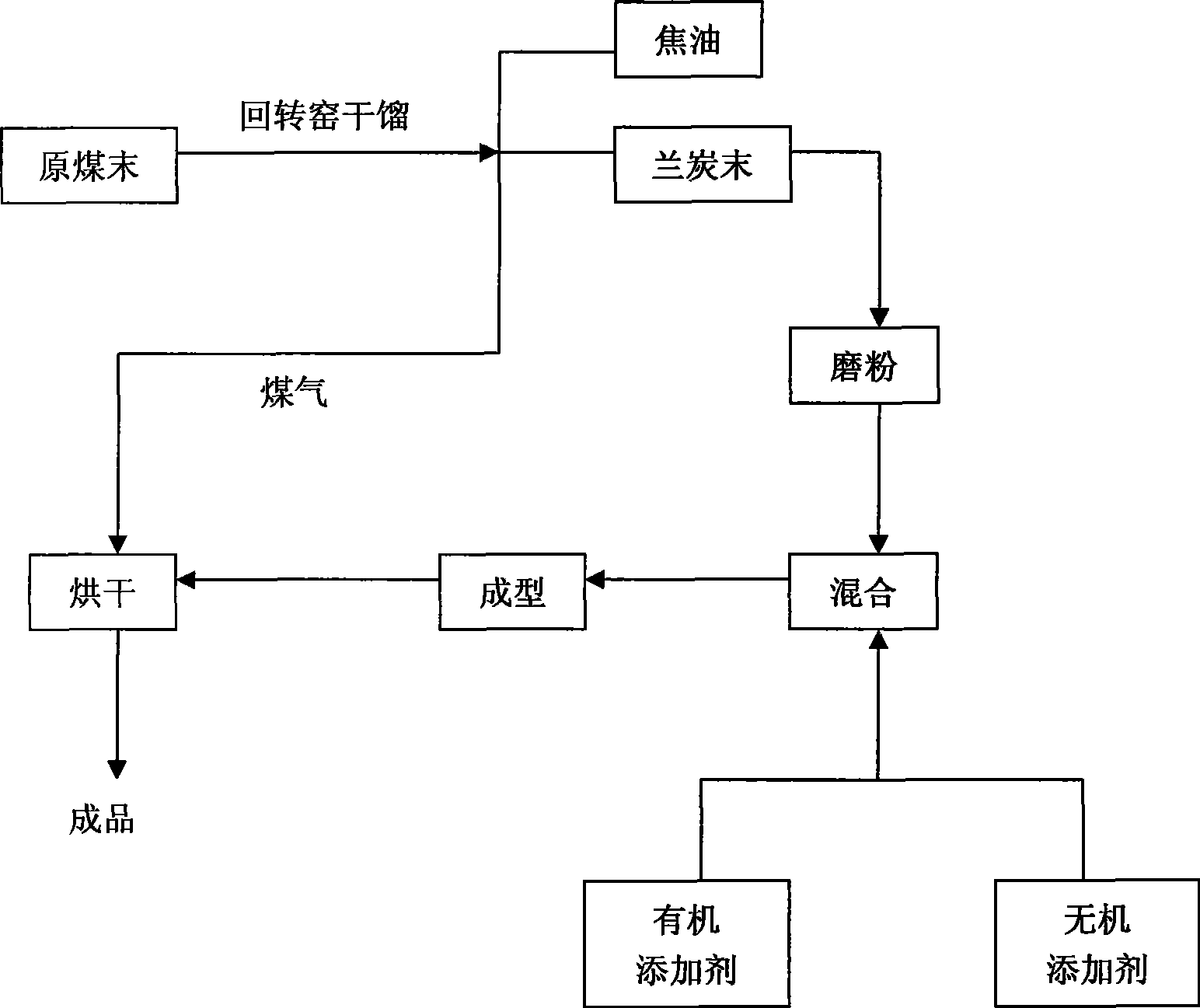

Image

Examples

specific Embodiment 1

[0011] Specific Example 1: A method for producing environmentally friendly anthracite briquettes with low-ash, low-sulfur, low-phosphorus, high-calorific oil-rich coal, using bituminous coal powder as raw material, and undergoing low-temperature dry distillation at 700°C for 2 hours Finally, tar, gas and semi-coke powder are produced, and the semi-coke powder is pulverized, added with binders and additives, mixed, extruded, and then dried to make environmentally friendly and clean anthracite briquettes; , the binder is a composite binder, including an organic binder and an inorganic binder, and the organic binder is polyvinyl alcohol and starch, adding 1 kg of polyvinyl alcohol per ton of briquette, 15 kg of starch, polyvinyl alcohol and The starch is prepared into a 5% emulsion, the inorganic binder is bentonite, 34kg is added after the bentonite is pulverized, and caustic soda, sulfur-fixing agent, waterproofing agent, quick-setting agent, synergist and combustion accelerant ...

specific Embodiment 2

[0012] Specific Example 2: A method for producing environmentally friendly anthracite briquettes with low-ash, low-sulfur, low-phosphorus, high-calorific oil-rich coal, using bituminous coal powder as raw material, and undergoing low-temperature dry distillation at 600°C for 6 hours Finally, tar, gas and semi-coke powder are produced, and the semi-coke powder is pulverized, added with binders and additives, mixed, extruded, and then dried to make environmentally friendly and clean anthracite briquettes; , described binding agent is composite binding agent, comprises organic binding agent and inorganic binding agent, organic binding agent is polyvinyl alcohol and starch, every ton of briquette adds polyvinyl alcohol 5kg, starch 6kg, polyvinyl alcohol and The starch is prepared into a 10% emulsion, the inorganic binder is bentonite, 40kg is added after the bentonite is pulverized, and caustic soda, sulfur-fixing agent, waterproofing agent, quick-setting agent, synergist and combu...

specific Embodiment 3

[0013] Specific Example 3: A method for producing environmentally friendly anthracite briquettes with low-ash, low-sulfur, low-phosphorus, high-calorific oil-rich coal, using bituminous coal powder as raw material, and undergoing low-temperature dry distillation at 650°C for 4 hours Finally, tar, gas and semi-coke powder are produced, and the semi-coke powder is pulverized, added with binders and additives, mixed, extruded, and then dried to make environmentally friendly and clean anthracite briquettes; , the binder is a composite binder, including organic binder and inorganic binder, the organic binder is polyvinyl alcohol and starch, and 1.5kg of polyvinyl alcohol, 10kg of starch, polyethylene Alcohol and starch are prepared into an 8% emulsion, the inorganic binder is bentonite, and 20kg is added after the bentonite is pulverized, and caustic soda, sulfur-fixing agent, waterproofing agent, quick-setting agent, synergist and combustion aid are added as additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com