Dual-channel porous turbulence pressure relief drilling tool for soft coal rock drilling, and construction method of drilling tool

A dual-channel, soft coal-rock technology, applied to drilling equipment and methods, drilling tools, percussion drilling, etc., can solve the problems of easy blockage, damage, and low drilling efficiency of drilling holes, and achieve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

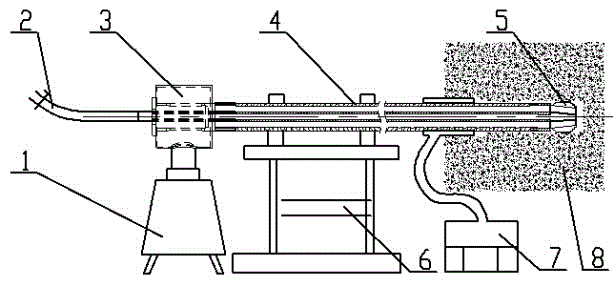

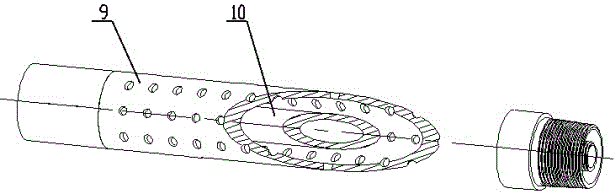

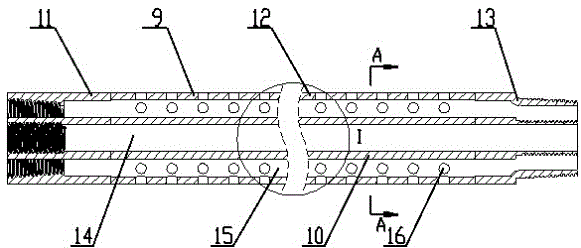

[0031] Embodiment one: if Figure 1 to Figure 9 As shown, the present invention is a dual-channel porous turbulent flow pressure relief drilling tool for soft coal and rock drilling and a construction method thereof, including a dual-channel porous turbulent flow pressure relief drill rod 4, a dual-channel drill bit 5, and a rotary slag discharge at the drill tail. Device 3, the drill tail rotary slagging device 3 is connected to the dual-channel porous turbulent flow pressure relief drill pipe 4 on the drilling rig, and the dual-channel drill bit 5 is installed on the front end of the dual-channel porous turbulent flow pressure relief drill pipe 4 . The double-channel porous turbulent flow pressure relief drill pipe 4 is composed of a porous outer drill pipe body 9 and an inner pipe 10 . The porous outer drill rod body 9 is composed of an internally threaded joint 13, a porous rod body 12 and an externally threaded joint 11. A plurality of small holes 16 are arranged on the r...

Embodiment 2

[0038] Embodiment two: if Figure 10 ~ Figure 13 As shown, the difference from Embodiment 1 is that the outer surface of the outer drill rod body 9 is provided with a helical rib 28, and the helical rib adopts a welding helical blade or a plasma coating process. When the rod rotates, the helical ribs on the surface of the drill pipe form a spiral conveying state, which can realize auxiliary slag discharge, and at the same time, it is beneficial to the surface of the drill pipe to dissipate heat and avoid the high temperature of the drilling tool caused by heat accumulation; on the other hand, the helical ribs on the surface of the drill pipe It can effectively improve the strength of the drill rod body 9 outside the hole, and indirectly prolong the service life of the drill rod. The construction method of embodiment two is the same as embodiment one.

Embodiment 3

[0039] Embodiment three: as Figure 14 ~ Figure 17 As shown, the difference from Embodiment 1 and Embodiment 2 is that the outer surface of the outer drill pipe body 9 is provided with a helical groove 29. The function of the helical groove is similar to that of Example 2, but its auxiliary slagging ability is weak, and its important The function is to exert its heat dissipation function in the stuck drill area, which can effectively prevent drilling gas combustion, drilling CO poisoning and other in-hole accidents formed in the stuck drill area. The construction method of embodiment three is the same as embodiment one and embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com