Method for treating copper scum using converter

A technology of copper scum and converter, which is applied in the field of copper scum treatment by converter, can solve the problems of high production cost, environmental pollution, low metal recovery rate, etc., and achieve the effect of improving the comprehensive utilization rate of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

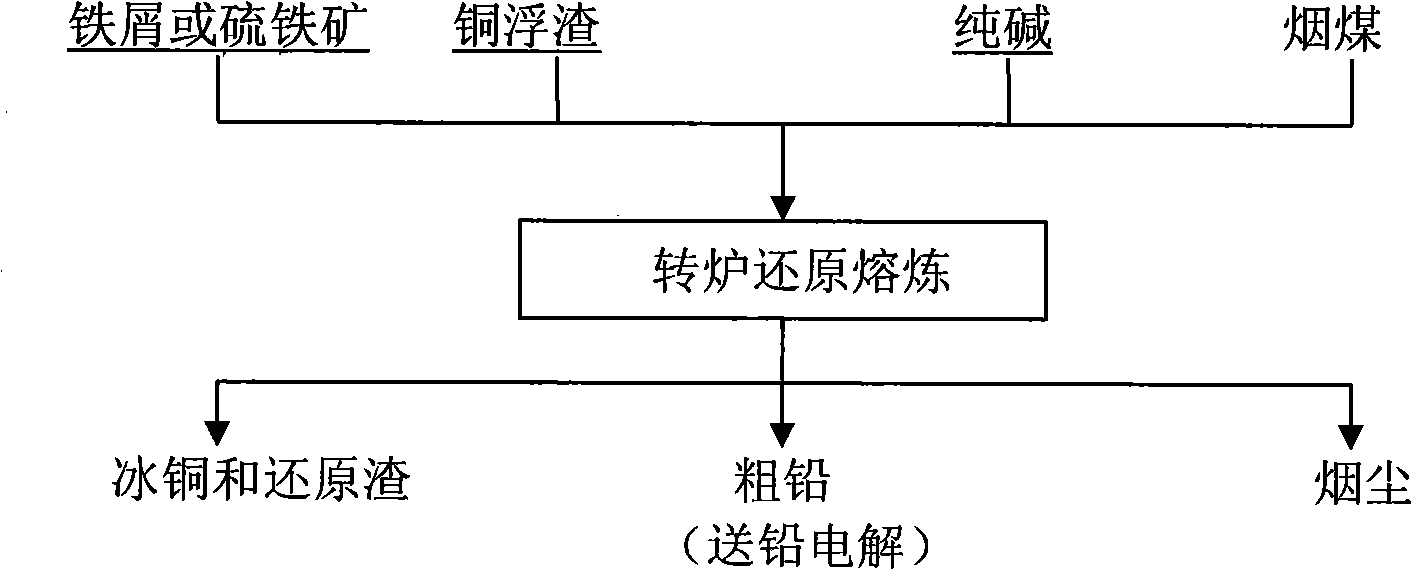

Image

Examples

Embodiment 1

[0020] Embodiment one: raw material copper scum composition: lead 68.9%, copper 13.58%, arsenic 5.78%, antimony 0.84%, according to the batching scheme of copper scum: soda ash: iron filings: bituminous coal=100: 10: 5: 5, material After the preparation is completed, add it to the converter twice, first recover the metallic lead in the copper scum at a temperature of 700-800°C, then increase the temperature to 1200°C to recover the lead in a combined state. Place copper matte at a temperature of ~1150°C, lower the temperature to 700-750°C and put rough lead, and remove the scum in the matte copper and rough lead. See Table 2 for technical indicators.

[0021] Table 2: Technical indicators of copper dross converter treatment

[0022] serial number

Embodiment 2

[0023] Embodiment two: raw material copper scum composition: lead 72.02%, copper 12.96%, arsenic 5.44%, antimony 0.75%, according to copper scum: soda ash: pyrite: the batching scheme of bituminous coal=100: 11: 7: 5 will After the materials are prepared, add them to the converter twice, first recover the metallic lead in the copper dross at a temperature of 700-800°C, and then raise the temperature to 1250°C to recover the lead in a combined state. Put matte copper at 1050~1150℃, lower the temperature to 700~750℃ and put crude lead. The obtained technical indicators are shown in Table 3.

[0024] Table 3: Technical indicators of copper dross converter treatment

[0025] serial number

Embodiment 3

[0026] Embodiment three: raw material copper scum composition: lead 67.66%, copper 13.85%, arsenic 5.87%, antimony 0.92%, according to the batching scheme of copper scum: soda ash: iron filings: bituminous coal=100: 9: 5: 5 will material After the preparation is completed, add it to the converter twice, first recover the metallic lead in the copper scum at a temperature of 700-800°C, then increase the temperature to 1200°C to recover the lead in a combined state. Place matte copper at a temperature of ~1150°C, and place rough lead at a temperature lowered to 700-750°C. The obtained technical indicators are shown in Table 4.

[0027] Table 4: Technical indicators of copper dross converter treatment

[0028] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com