Method for realizing SNCR and SCR combined denitration by using coal-fired boiler

A technology for a coal-fired boiler and a realization method, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high operation cost, low denitration rate, complex system, etc., and achieve low operation cost and broad application prospects. , the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

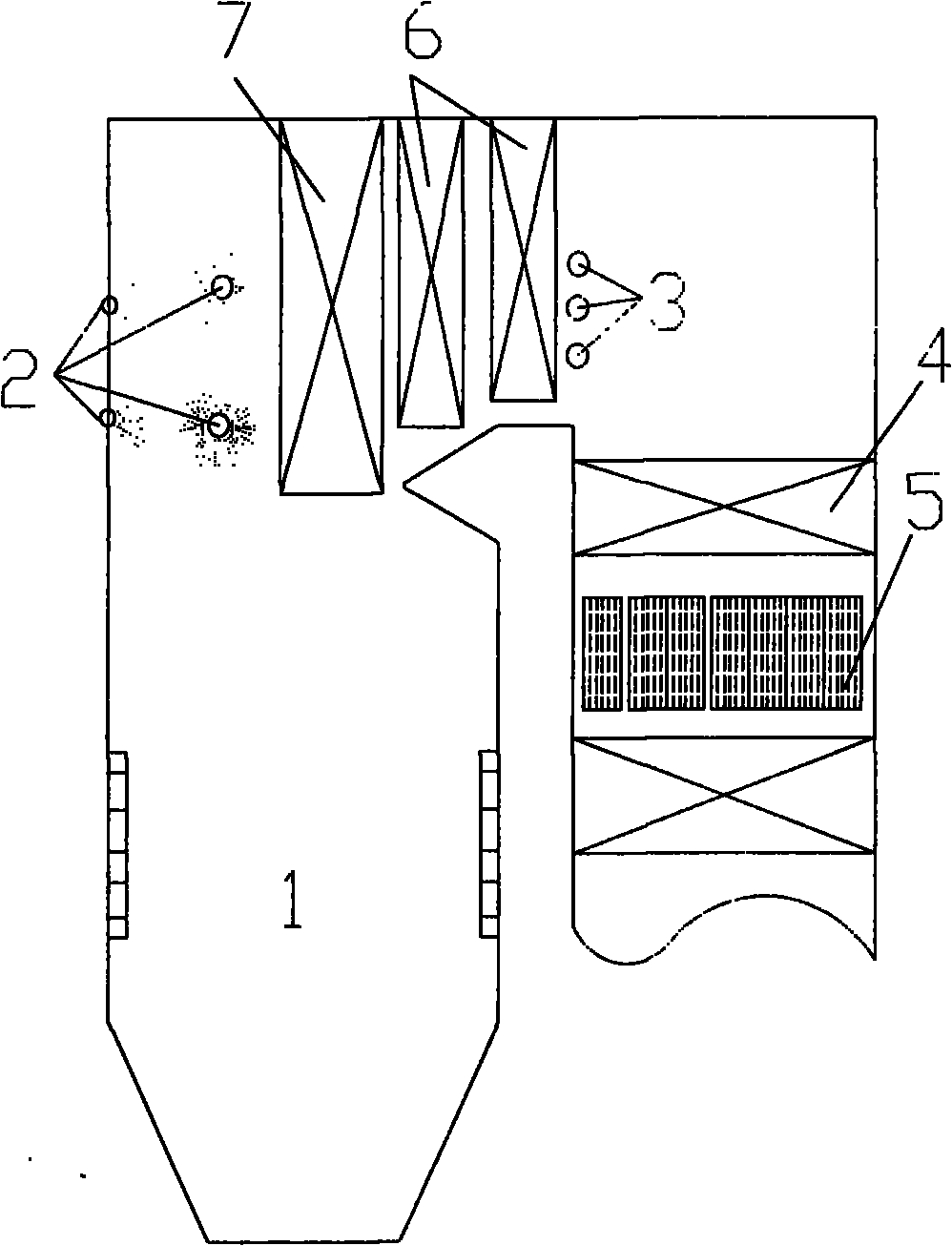

[0026] Such as figure 1 What is shown is a method for realizing the joint denitrification of coal-fired boiler SNCR and SCR. Fuel combustion produces 350mg / m in boiler furnace 1 3 The left and right NO flows upward with the flue gas, and a reducing agent spray gun 2 is arranged on the upper part of the furnace. A total of 10 reducing agent spray guns are arranged in two layers on the front wall and side wall, all of which are single-nozzle spray guns. The flue gas temperature in the furnace at the elevation of the spray gun arrangement is 800-950°C. The reducing agent is urea solution with a concentration of 5%-15%, and the molar ratio of the injection amount of the reducing agent to the NO in the flue gas is 1.2:1-1.6:1. The urea solution sprayed into the furnace by the reducing agent spray gun 2 evaporates while mixing with the flue gas, and decomposes into NH 3 and HCNO. NH 3 And part of HNCO reacts with NO to generate N 2 , reducing the NO concentration, part of the...

specific Embodiment 2

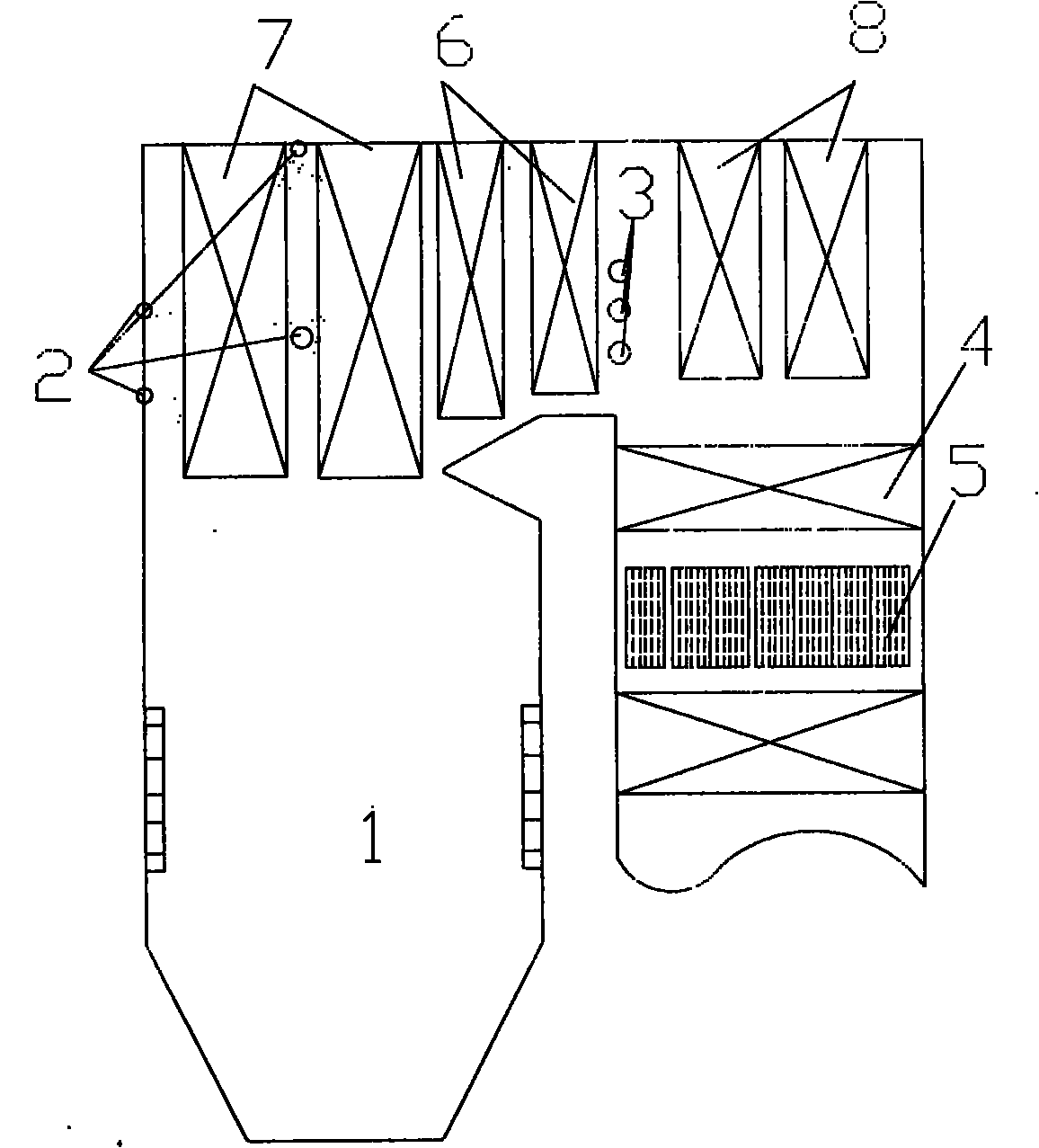

[0028] Such as figure 2 What is shown is a method for realizing the joint denitrification of coal-fired boiler SNCR and SCR. Fuel combustion produces 400mg / m in boiler furnace 1 3 The left and right NO flows upward with the flue gas, and the reducing agent spray gun 2 is arranged on the upper part of the furnace. The specific arrangement is as follows: a total of 14 single-nozzle spray guns are arranged on the front wall in two layers; Seven single-nozzle spray guns are arranged along the width direction on the top. The flue gas temperature in the furnace at the elevation of the spray gun arrangement is 700-850°C. The reducing agent is ammonia solution with a concentration of 5-12%, and the molar ratio of the injection amount of the reducing agent to the NO in the flue gas is 1:1-1.5:1. The ammonia solution sprayed into the furnace from the reducing agent spray gun 2 evaporates while mixing with the flue gas. NH 3 Part of it undergoes a reduction reaction with NO to gene...

specific Embodiment 3

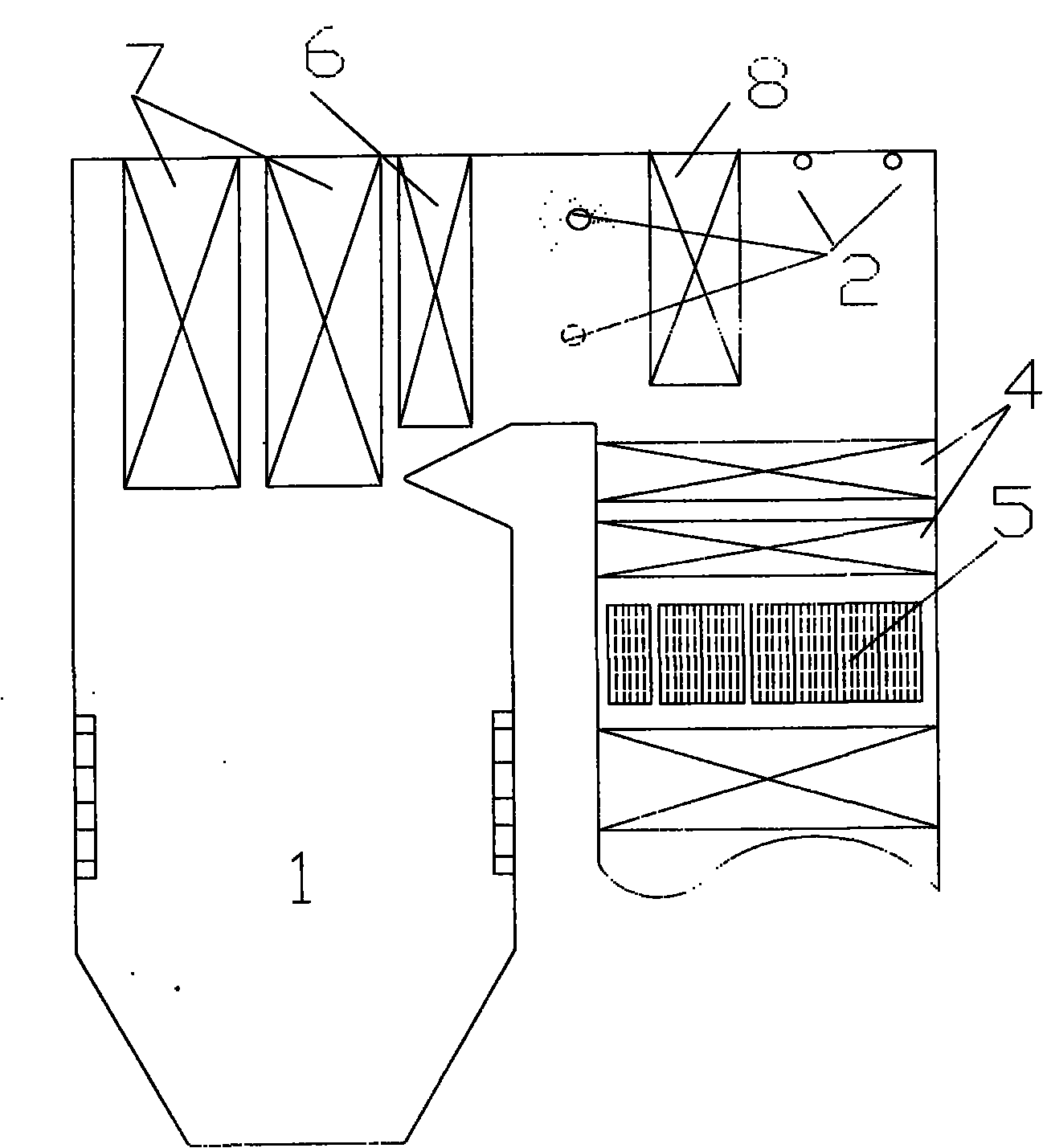

[0030] Such as image 3 What is shown is a method for realizing the joint denitrification of coal-fired boiler SNCR and SCR. Fuel combustion produces 350mg / m in boiler furnace 1 3The left and right NO flows upward with the flue gas, and flows through the panel heating surface 7 and the horizontal convection heating surface 6 . Reductant spray guns 2 are arranged in the steering chamber, and the specific arrangement is as follows: two multi-nozzle spray guns are arranged on the left and right side walls at the entrance of the steering chamber; two rows are arranged on the top of the rear steering chamber, and each row is arranged with 8 single-nozzle spray guns along the width direction . The flue gas temperature in the furnace where the spray gun is arranged is 600-800°C. The reducing agent is ammonia solution with a concentration of 12% to 20%, and the molar ratio of the injection amount of the reducing agent to the NO in the flue gas is 1.5:1 to 2:1. The ammonia solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com