Very soft thick coal seam forepoling hold top coal caving mining method and hydraulic support structure

A technology of hydraulic support and advanced support, which is applied in mine roof support, ground mining, mining equipment, etc., and can solve problems such as top coal chipping, low recovery rate, and uncontrollable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

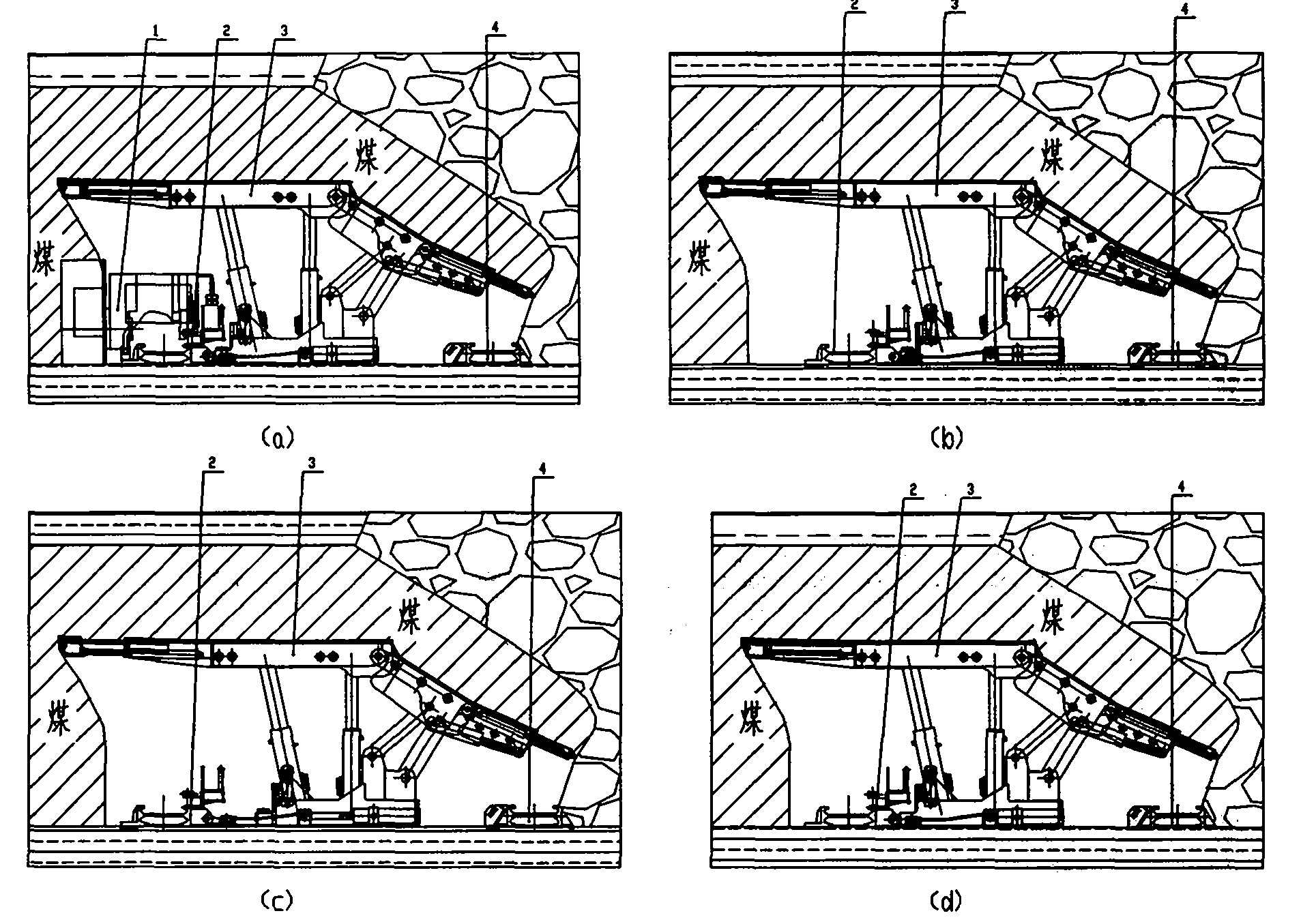

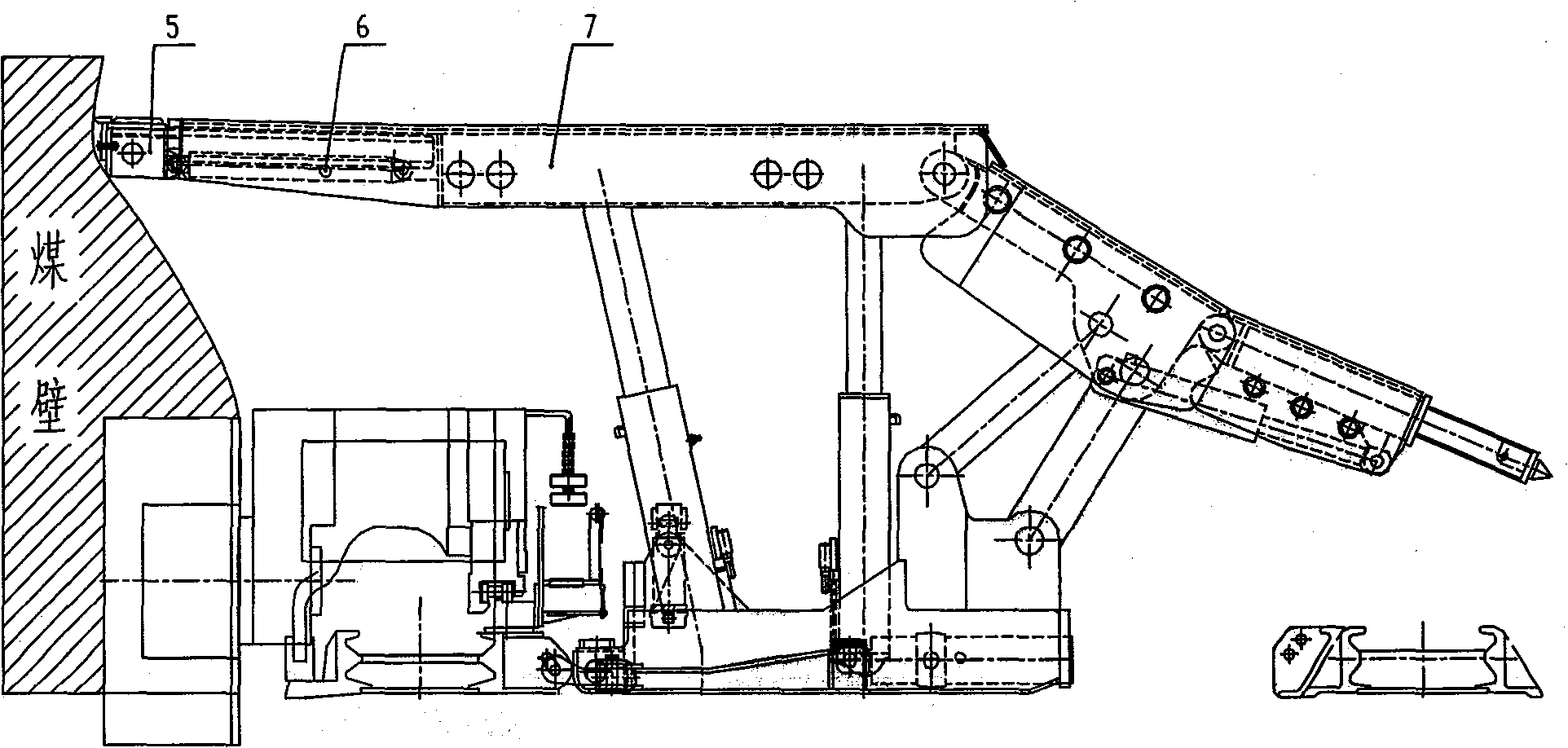

[0011] figure 1 The patented ultra-soft and thick coal seam advance support hugging coal mining method shown in the present invention mainly consists of a shearer (1), a front conveyor (2), a caving hydraulic support (3), and a rear conveyor (4) and other components. Under the condition of extremely soft coal seam, the matching relationship between the shearer (1) and the caving hydraulic support (3) is advanced support, that is, the shearer (1) drum is in the top coal caving position at the beginning of the machine cutting cycle. The hydraulic support (3) top beam (7) cuts bottom coal and loads coal, such as figure 1 As shown in (a), at this time, the roof of the coal wall on the working face has reached a dynamic equilibrium, the coal mining efficiency is high, and the safety is guaranteed. With the progress of coal loading, the coal wall will further collapse. Stretch out the shovel-type telescopic beam (5), if the top-coal sheet is not smooth, the top-coal can be leveled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com