Hole drilling and protecting method of drilling tool for soft coal seam gas extraction hole drilling and protecting

A soft coal seam and gas drainage technology, which is applied in the field of coal mine gas drainage drilling construction, can solve the problems of inability to remove the drill bit, economic loss, and influence on the decentralization of the screen pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

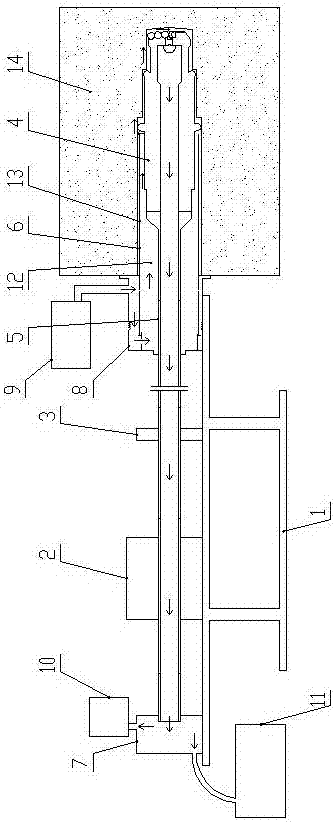

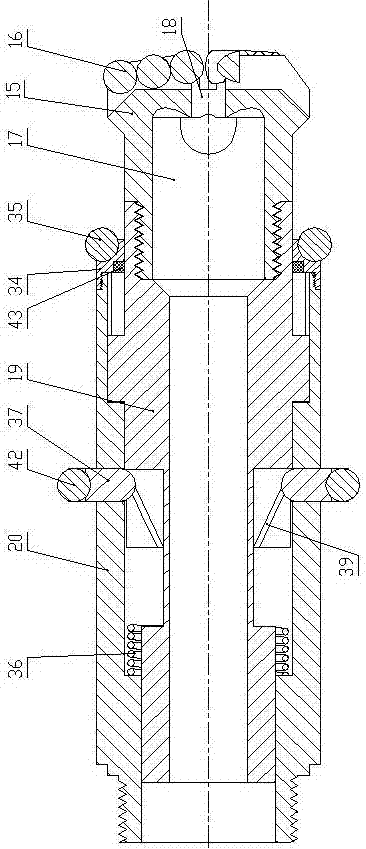

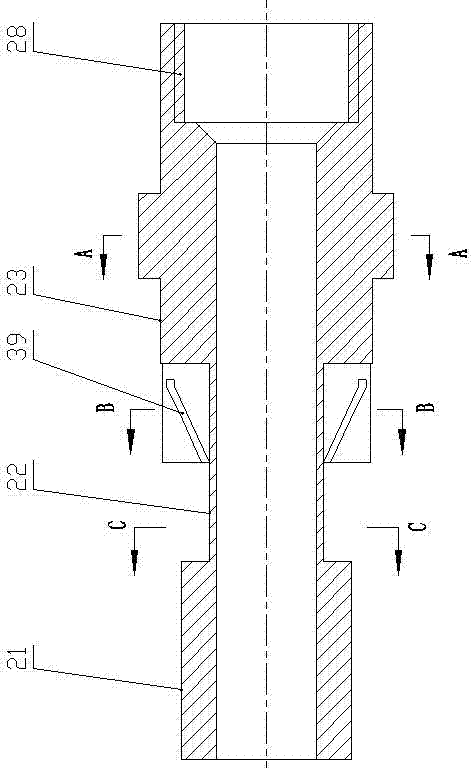

[0027] Such as Figure 1-Figure 10As shown in the present invention, the drilling tool for drilling and protecting holes for gas drainage in soft coal seams includes a bracket 1, a power drive device 2, a guide support frame 3, a hollow internal slag discharge variable diameter drill bit 4, and a hollow smooth surface drill rod 5 , PVC hole protection pipe 6, the first buffer tank 7, the second buffer tank 8, water supply device 9, air supply device 10 and slag collection container 11; PVC hole protection pipe 6 sets outside the hollow smooth drill pipe 5, PVC protection An annular channel 12 is formed between the inner wall of the hole pipe 6 and the hollow smooth drill rod 5, and the direction of drilling is from back to front. The rear end of the hollow smooth drill rod 5 is connected with the first buffer box 7, and the first The lower part of the buffer box 7 is connected to the slag collection container 11, the top of the first buffer box 7 is connected to the air supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com